Charcoal negative electrode material and its preparation method

A negative electrode material, carbon black technology, applied in the direction of battery electrodes, electrical components, circuits, etc., can solve the problems of cladding layer cracking, particle agglomeration, and natural graphite that cannot be overcome, so as to achieve structural stability, increase structural stability, It is beneficial to the effect of pole piece processing

Active Publication Date: 2007-02-07

福建杉杉科技有限公司

View PDF5 Cites 20 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

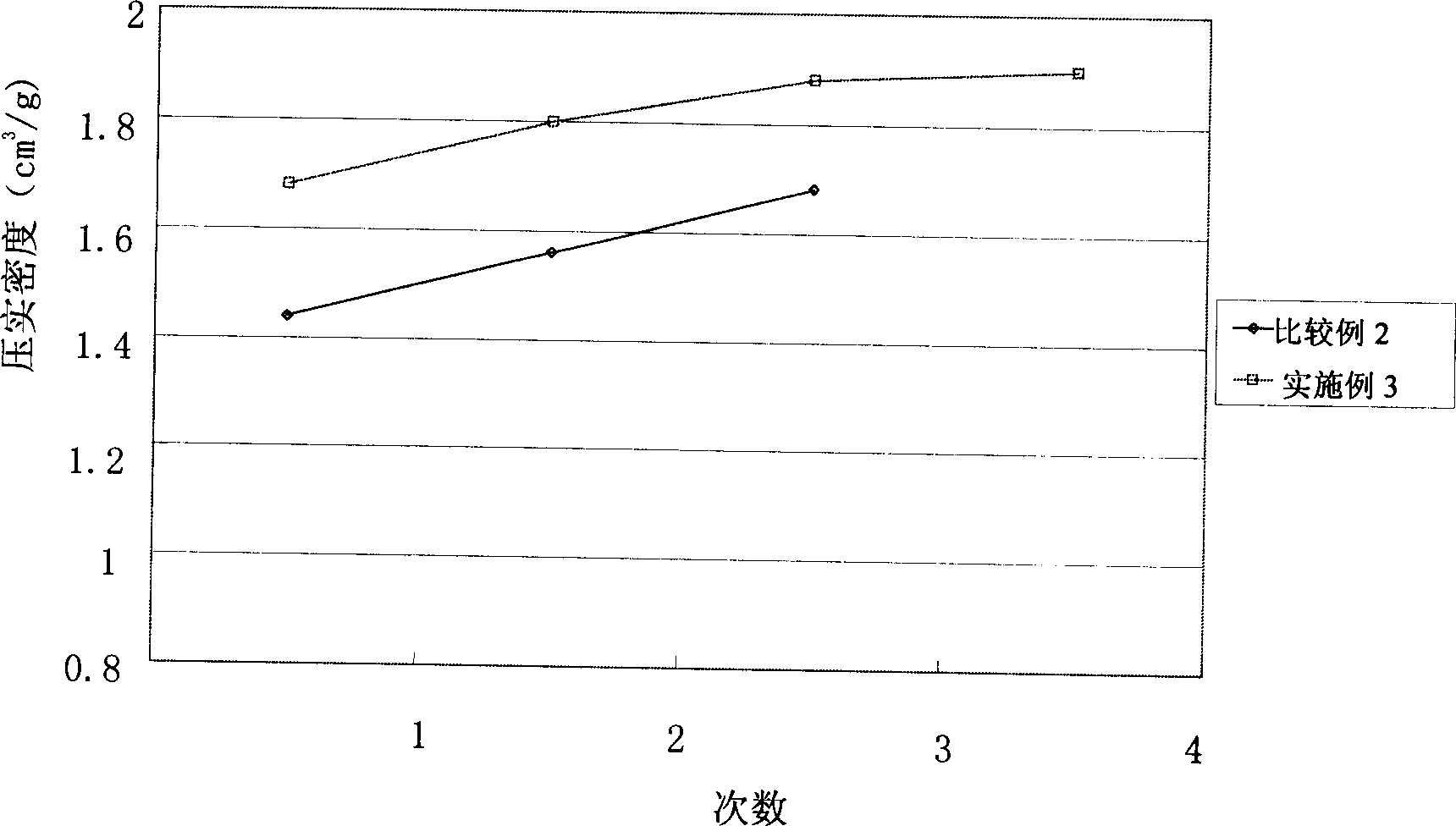

The low-crystallinity carbon coated in the above-mentioned patents is low in processing temperature, and there are few microcrystals in an ordered state in the structure. It is still in a state of random stratification, and the material has high strength and poor toughness. When the compacted density is high, It is easy to break the cladding layer, resulting in the exposure of internal materials

US patent US20040023115 proposes the use of spherical natural graphite mixed with graphitized mesophase powder to obtain graphite materials that are easy to roll with high density and can be used to prepare lithium batteries with high energy density, but the weakness of natural graphite cannot be overcome

However, grap

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Discharge capacity | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a new carbon cathode, which comprises: graphite powder and the graphitized middle phase cover layer, wherein it is characterized in that: the average thickness of middle layer is 0.5-8 mum. And the invention also discloses a relative preparation, which comprises: (1) mixing 5-45% graphite powder and 95-55% pitch, adding the aggregation restrain agent at 0.5-5%, to polymerize at 380-480Deg. C; (2) separating; (3) drying; (4) carbonizing; (5) graphitizing. The invention covers graphitized middle phase layer over the graphite, to obtain better property, and it can restrain the solid particle aggregation, to control the diameter.

Description

technical field [0001] The invention relates to a carbon negative electrode material and a preparation method thereof, in particular to a graphite carbon negative electrode material containing a coating layer and a preparation method thereof. Background technique [0002] Carbon materials are widely used in many fields due to their stable chemical properties, high electronic conductivity, intercalation to form intercalation compounds, and heat resistance, thermal shock resistance, and high specific strength. . Especially in recent years, the development of carbon anode materials for lithium-ion batteries has been active. Natural graphite, artificial graphite and special artificial graphite-graphitized mesophase (including mesophase carbon microspheres and monolithic mesophase powder) have been used in commercial batteries. Several types of carbon materials. Natural graphite has an ideal layered structure, has a high capacitance (>350mAh / g), and is easy to compact (>1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): H01M4/58C01B31/02H01M4/583

CPCY02E60/10

Inventor 李辉张殿浩

Owner 福建杉杉科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com