Silver-nickel composite electrical contact material with nickel distributed in net-shaped mode, and preparation method thereof

A technology of electric contact material and mesh, applied in the direction of cable/conductor manufacturing, contacts, circuits, etc., to achieve high tap density, short process flow, and easy-to-obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

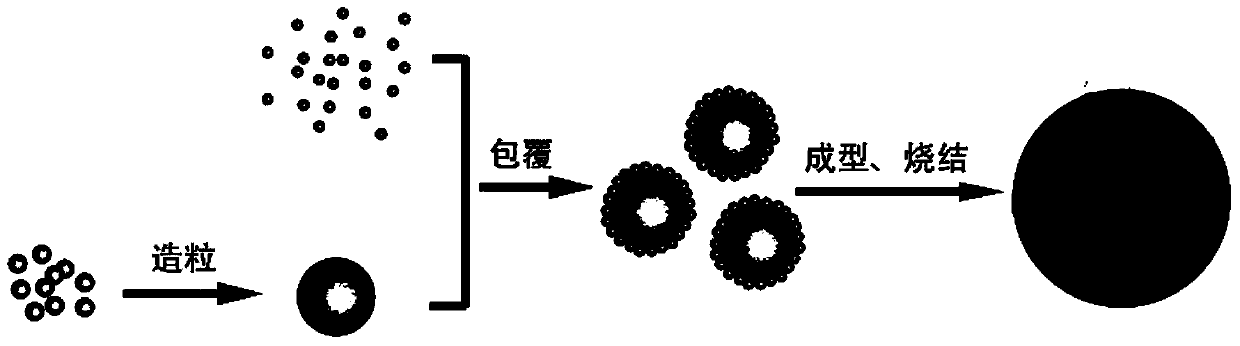

Method used

Image

Examples

Embodiment 1

[0020] The silver-nickel composite electrical contact material with nickel network distribution, the nickel is distributed in the silver matrix in a continuous network, and the mass content of each component in the silver-nickel composite electrical contact material is: silver: 50%; nickel: 50%.

[0021] The preparation method of the silver-nickel composite electrical contact material of the nickel mesh distribution of the present embodiment is as follows:

[0022] Step 1: Preparation of silver particles by dry granulation method: put the silver powder into a steel mold, press it into a green body under a pressure of 20 MPa, then crush and sieve to obtain silver particles with a particle size range of 250-550 μm, and transfer the silver particles into Muffle furnace annealing, annealing temperature 300 ° C, annealing time 3 hours, cooling with the furnace;

[0023] Step 2: taking silver particles and nickel powder with an average particle size of 0.1 μm by mass content;

[00...

Embodiment 2

[0028] The silver-nickel composite electrical contact material with nickel network distribution, the nickel is distributed in the silver matrix in a continuous network, and the mass content of each component in the silver-nickel composite electrical contact material is: silver: 50%; nickel: 50%.

[0029] The preparation method of the silver-nickel composite electrical contact material of the nickel mesh distribution of the present embodiment is as follows:

[0030] Step 1: Prepare silver particles by wet granulation method: spray water into the silver powder, the amount of water is 0.4% of the total mass of the silver powder, to make the surface wet, after the particles are agglomerated, sieve and dry, the drying temperature 40°C, drying time 4 hours, prepare silver particles with a particle size range of 180-250 μm, transfer the silver particles to a muffle furnace for annealing, annealing temperature 300°C, annealing time 6 hours, and cool with the furnace;

[0031] Step 2: ...

Embodiment 3

[0035] The silver-nickel composite electrical contact material with nickel network distribution, the nickel is distributed in the silver matrix in a continuous network, and the mass content of each component in the silver-nickel composite electrical contact material is: silver: 75%; nickel: 25%.

[0036] The preparation method of the silver-nickel composite electrical contact material of the nickel mesh distribution of the present embodiment is as follows:

[0037] Step 1: Preparation of silver particles by dry granulation method: put the silver powder into a steel mold, press it into a green body under a pressure of 26 MPa, then crush and sieve to obtain silver particles with a particle size range of 550-830 μm, and transfer the silver particles into Muffle furnace annealing, annealing temperature 500 ° C, annealing time 1 hour, cooling with the furnace;

[0038] Step 2: taking silver particles and nickel powder with an average particle size of 48 μm by mass content;

[0039...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com