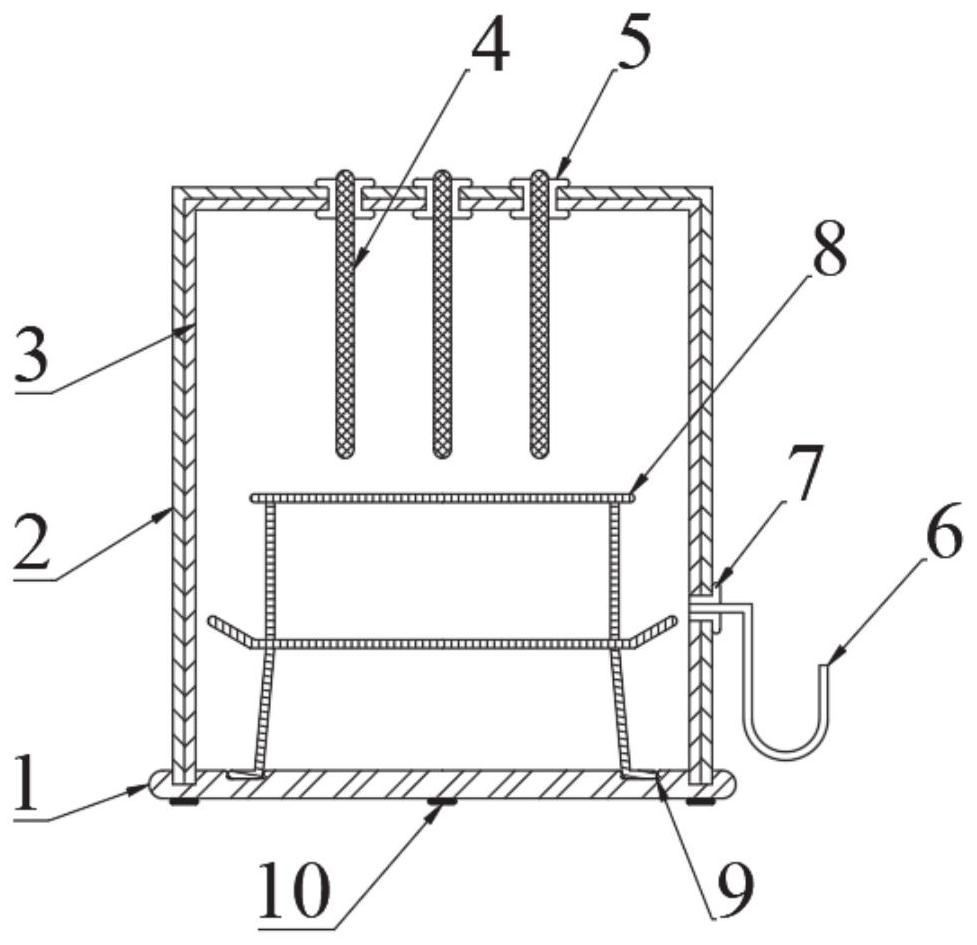

Device for modifying hydrophobic property of MOFs through positive and negative micropressure conversion, and preparation method and application of hydrophobic MOFs

A transformation and modification technology, applied in the field of adsorption catalyst preparation, can solve the problems of inability to determine hydrophobic materials and reduce the specific surface area of materials, and achieve the effects of improved hydrophobic performance, high porosity, and small impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

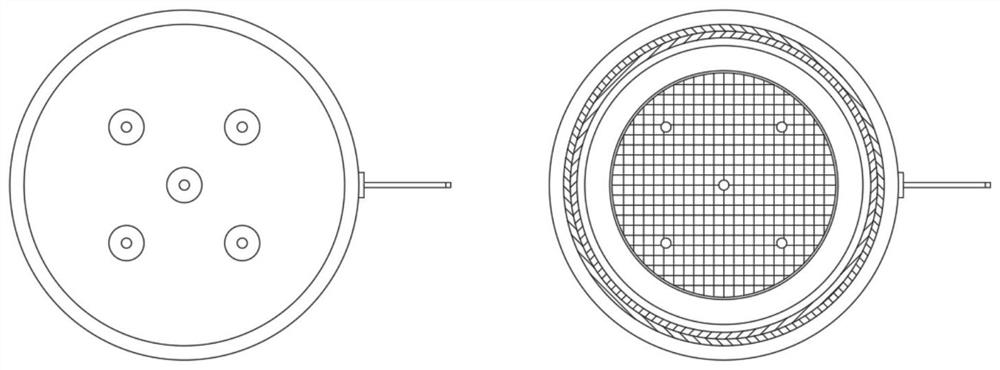

Method used

Image

Examples

Embodiment 1

[0069] a) Weigh 0.14mmol of Fe(NO 3 ) 3 9H 2 O, 1.86mmol of Co(NO 3 ) 2 ·6H 2 O was dissolved in 10ml of methanol, and stirred at a speed of 1000r / min in a water bath at 60°C for 20min; weighed 50mmol of 2-methylimidazole and dissolved in 20ml of methanol, and stirred at a speed of 1000r / min in a water bath at 60°C Stir at a speed of 1500r / min for 20min; mix the above two solutions, and stir for 20min at a speed of 1500r / min in a water bath at 60°C; pour into a beaker after stirring and seal it at room temperature for 12h;

[0070]b) After standing still, remove the supernatant, add 50ml methanol to the beaker, and transfer the mixture to a centrifuge tube; put the centrifuge tube containing the mixture into an ultrasonic cleaner, and shake at a temperature of 60°C for 20min ; After shaking, clean the centrifuge tube, put it into a centrifuge, and centrifuge at a speed of 4000r / min for 20min; after centrifugation, remove the supernatant, add 20ml of methanol, and repeat c...

Embodiment 2

[0083] a) Weigh 0.14mmol of Co(NO 3 ) 2 ·6H 2 O, 1.86mmol of Fe(NO 3 ) 3 9H 2 O, dissolved in 23ml N,N-dimethylformamide (DMF), and stirred at a speed of 1000r / min in a water bath at 50°C for 15min; weighed 2mmol of terephthalic acid (H 2 BDC) was dissolved in 15ml of DMF, and stirred at a speed of 2000r / min in a water bath at 50°C for 15min; the above two solutions were mixed, and stirred at a speed of 2000r / min in a water bath at 50°C for 15min; After stirring, cool to room temperature, pour the solution into the PTFE lining and put it into the reaction kettle, tighten it and put it in the drying oven, and heat it at 120°C for 12h;

[0084] b) After the heating is over, remove the supernatant after standing to room temperature, add 30ml of DMF to the polytetrafluoroethylene liner, and transfer the mixture to a centrifuge tube, add 10ml of ethanol, 10ml of deionized water to the mixture; Put the centrifuge tube containing the mixture into an ultrasonic cleaner and shake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com