Method for preparing tungsten carbide by using regeneration tungsten powder

A technology of tungsten carbide and tungsten powder, applied in the direction of carbides and carbides of tungsten/molybdenum, to achieve the effect of promoting decomposition, easy fragmentation, and accelerating the rate of carbonization reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

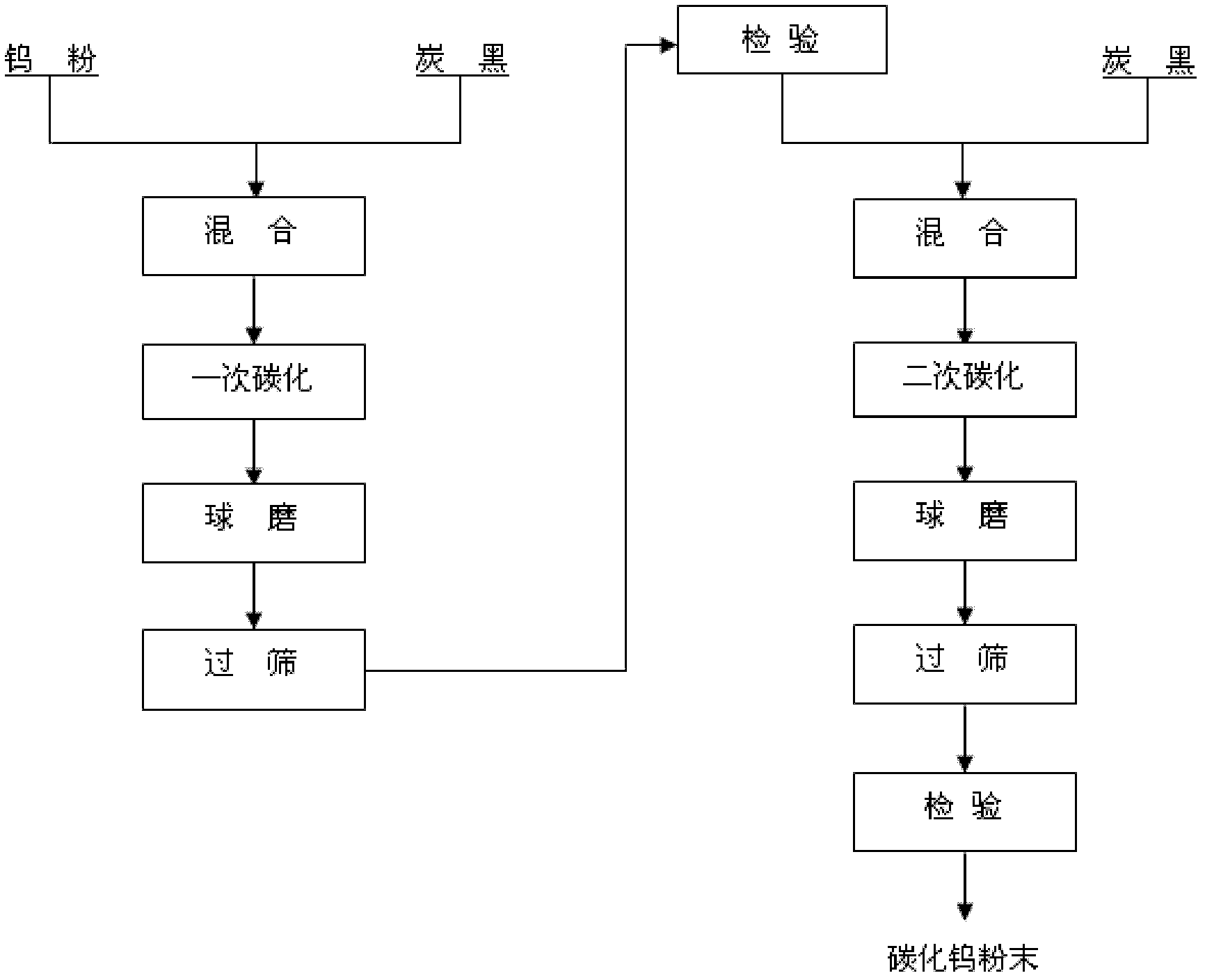

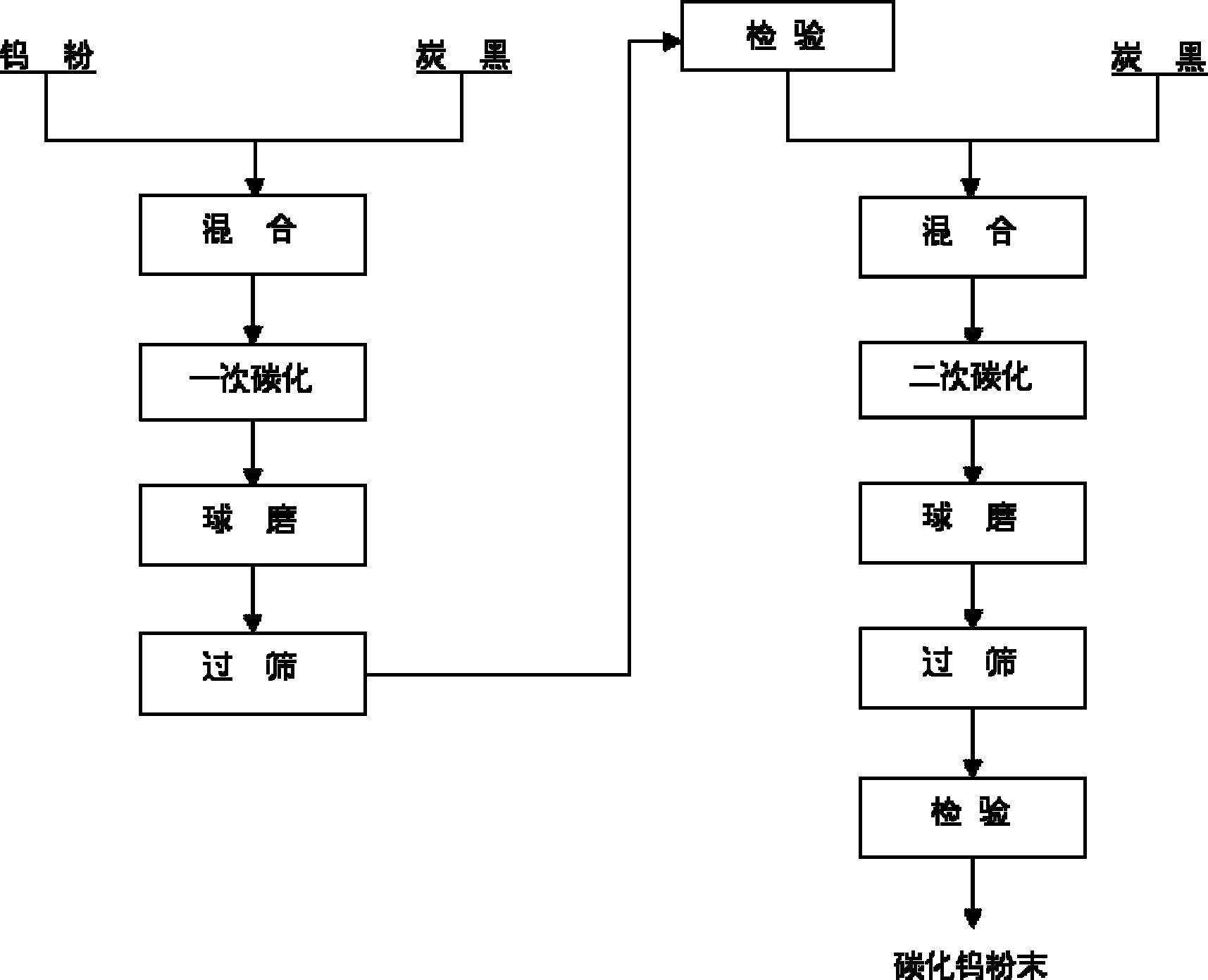

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Weigh 5 kg of tungsten powder with a Fischer particle size of 50 microns and a purity of 99.5%, and 0.175 kg of carbon black with a purity greater than 99%, and ball mill and mix them in a ball mill. After fully mixing evenly, transfer the mixture into a graphite boat, and slowly push it into the high temperature zone of a Φ120mm×1200mm graphite carbon tube furnace for primary carbonization. During the carbonization process, hydrogen gas is introduced at the same time, and the flow rate of hydrogen gas is controlled at 1.0 L / min. The carbonization temperature in the high temperature zone of the graphite carbon tube furnace is controlled at 1950°C, and the stay time of the boat in the high temperature zone is controlled at 80 minutes. After the primary carbonization is completed, the boat is slowly pushed out of the high-temperature zone of the graphite carbon tube furnace, and the primary carbonized material is obtained after it is slowly cooled. The carbo...

Embodiment 2

[0027] Example 2: Weigh 5 kg of tungsten powder with a Fischer particle size of 10 microns and a purity of 99.5%, and 0.160 kg of carbon black with a purity greater than 99%, and ball mill and mix them in a ball mill. After fully mixing evenly, transfer the mixture into a graphite boat, slowly push it into the high-temperature zone of a Φ120mm×1200mm graphite carbon tube furnace for primary carbonization. The carbonization temperature in the high temperature zone of the graphite carbon tube furnace is controlled at 1850°C, and the stay time of the boat in the high temperature zone is controlled at 50 minutes. After the primary carbonization is completed, the boat is slowly pushed out of the high-temperature zone of the graphite carbon tube furnace, and after it is slowly cooled, the primary carbonized material is obtained, and its carbon content is 3.0% according to sampling analysis. Then weigh 0.165kg of carbon black with a purity of more than 99% and the primary carbonized ...

Embodiment 3

[0028] Embodiment 3: Weigh 5 kg of tungsten powder with a Fischer particle size of 20 microns and a purity of 99.5%, and 0.160 kg of carbon black with a purity greater than 99%, and ball mill and mix them in a ball mill. After fully mixing evenly, transfer the mixture into a graphite boat, and slowly push it into the high temperature zone of a Φ120mm×1200mm graphite carbon tube furnace for primary carbonization. During the carbonization process, hydrogen gas is introduced at the same time, and the flow rate of hydrogen gas is controlled at 1.0 L / min. The carbonization temperature in the high temperature zone of the graphite carbon tube furnace is controlled at 1900°C, and the stay time of the boat in the high temperature zone is controlled at 60 minutes. After the primary carbonization is completed, the boat is slowly pushed out of the high-temperature zone of the graphite carbon tube furnace, and the primary carbonized material is obtained after it is slowly cooled. The carbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com