Lignin heavy metal ion adsorbent and preparation method thereof

A technology of heavy metal ions and adsorbents, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve problems such as easy solubility in water and low adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

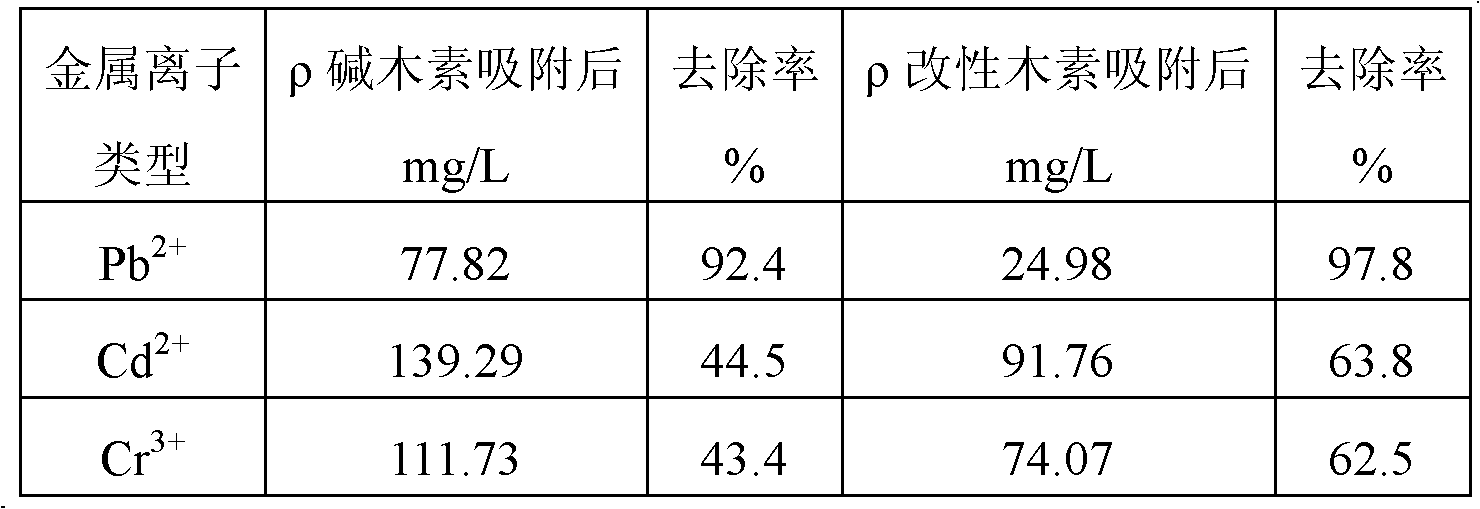

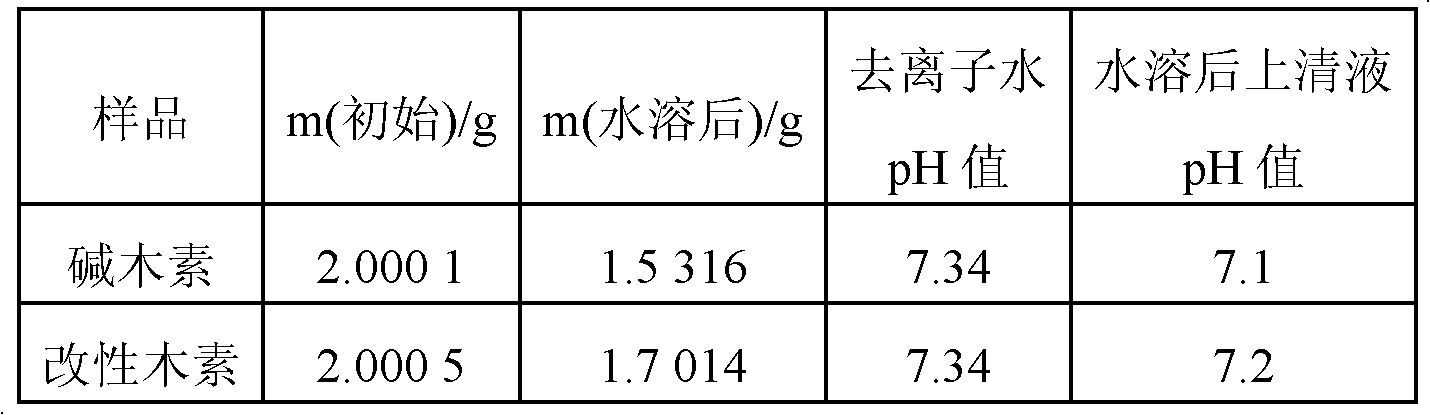

Examples

Embodiment 1

[0030] The first step, the extraction of alkali lignin

[0031] Weigh 1 kg of dry reed raw material, cook with 5 kg of 20wt% sodium hydroxide for 3.5 hours, heat up for 1.5 hours, keep warm for 2 hours, and keep warm at 170°C. After the cooking is completed, collect the black liquor, adjust the pH value of the black liquor to about 8 with 20wt% sulfuric acid, centrifuge at 5000r / min for 30min to remove precipitated impurities, then adjust the pH value to 3, and centrifuge at 5000r / min for 30min. The precipitated substance was washed with deionized water to remove excess acid until the pH was 7, and dried in a vacuum oven at 80°C to a moisture content of 5%, and the obtained substance was called alkali lignin. Pass through a 40-mesh sieve after drying.

[0032] The second step, hydroxymethylation

[0033] Add 2ml of formaldehyde solution with a mass fraction of 95% to 10g of alkali lignin, add 5ml of 0.1mol / L sodium hydroxide, and react at 80°C for 1.5h.

[0034] The third s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com