Nitrogen-containing silicon-oxygen-carbon compound composite negative electrode material of lithium ion secondary battery and preparation method

A technology for secondary batteries and negative electrode materials, applied in secondary batteries, battery electrodes, negative electrodes, etc., can solve the problems that affect the commercialization of silicon-based negative electrode materials, shorten the service life, and poor electrical conductivity, and achieve improved electrical conductivity. and cycle performance, improved surface properties, and the effect of improved cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

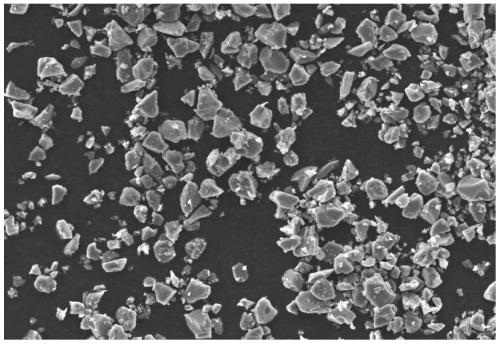

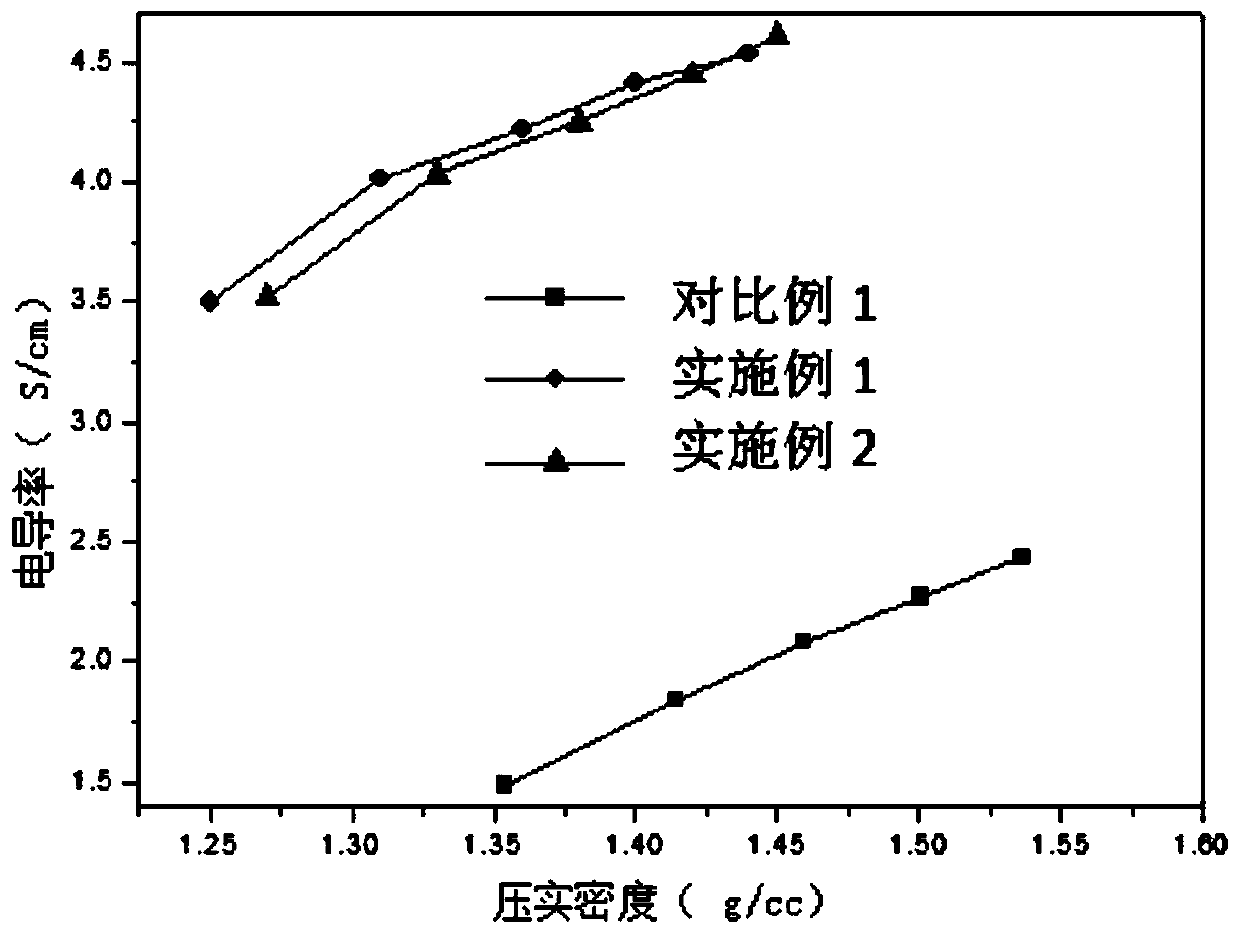

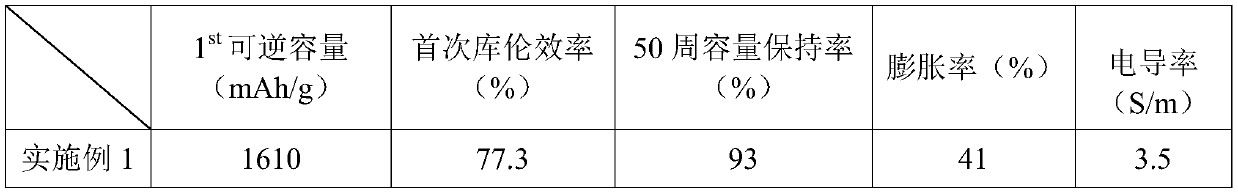

Embodiment 1

[0029] Dissolve tetraethyl orthosilicate in aqueous solution, the mass ratio of tetraethyl orthosilicate to water is 1:5, add hydrochloric acid to adjust PH=2, heat in a water bath with mechanical stirring, set the temperature at 60°C, and set the stirring speed 200rpm, the stirring time is 30min, then add citric acid, the molar ratio of tetraethyl orthosilicate to citric acid is 1:0.5, the temperature and stirring speed remain unchanged, the stirring time is 120min, then add melamine, tetraethyl orthosilicate The molar ratio of ester to melamine is 1:0.2, the temperature and stirring speed are kept constant, and the stirring time is 120min. After the reaction is completed, it is dried in an oven at 80°C. Put the dried material into a box furnace for roasting, the roasting temperature is 1000°C, under the protection of nitrogen atmosphere, the heating rate is 3°C / min, and the temperature is kept for 6h. After cooling, the semi-finished nitrogen-containing silicon-oxygen-carbon ...

Embodiment 2

[0031] Dissolve tetraethyl orthosilicate in aqueous solution, the mass ratio of tetraethyl orthosilicate to water is 1:5, add hydrochloric acid to adjust PH=2, heat in a water bath with mechanical stirring, set the temperature at 60°C, and set the stirring speed 200rpm, the stirring time is 30min, then add citric acid, the molar ratio of tetraethyl orthosilicate to citric acid is 1:0.8, the temperature and stirring speed remain unchanged, the stirring time is 120min, then add melamine, tetraethyl orthosilicate The molar ratio of ester to melamine is 1:0.4, the temperature and stirring speed are kept constant, and the stirring time is 120min. After the reaction is completed, it is dried in an oven at 80°C. Put the dried material into a box furnace for roasting, the roasting temperature is 1000°C, under the protection of nitrogen atmosphere, the heating rate is 3°C / min, and the temperature is kept for 6h. After cooling, the semi-finished nitrogen-containing silicon-oxygen-carbon ...

Embodiment 3

[0033]Dissolve tetraethyl orthosilicate in aqueous solution, the mass ratio of tetraethyl orthosilicate to water is 1:5, add hydrochloric acid to adjust PH=2, heat in a water bath with mechanical stirring, set the temperature at 60°C, and set the stirring speed 200rpm, the stirring time is 30min, then add citric acid, the molar ratio of tetraethyl orthosilicate to citric acid is 1:1, the temperature and stirring speed remain unchanged, the stirring time is 120min, then add melamine, tetraethyl orthosilicate The molar ratio of ester to melamine is 1:0.6, the temperature and stirring speed are kept constant, and the stirring time is 120min. After the reaction is completed, it is dried in an oven at 80°C. Put the dried material into a box furnace for roasting, the roasting temperature is 1000°C, under the protection of nitrogen atmosphere, the heating rate is 3°C / min, and the temperature is kept for 6h. After cooling, the semi-finished nitrogen-containing silicon-oxygen-carbon com...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com