Preparation and surface modification method of stable titanium dioxide particle

A titanium dioxide and surface modification technology, applied in the direction of titanium dioxide, titanium oxide/hydroxide, etc., can solve the problems of preparation and control blank, and achieve the effect of stable and consistent properties, high yield and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

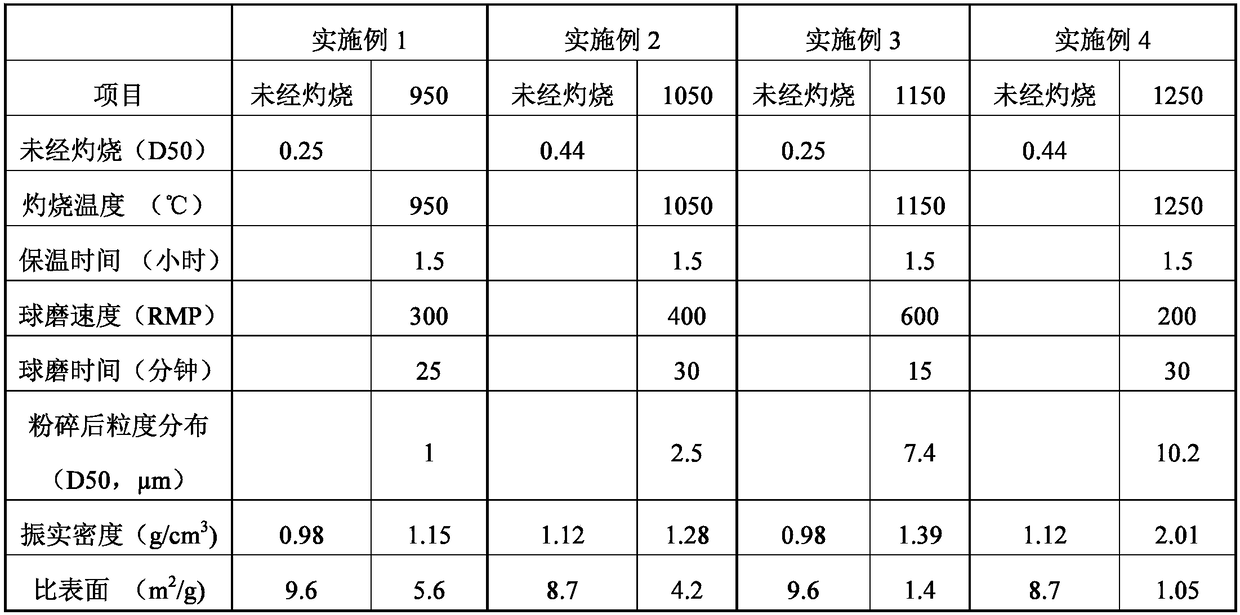

Embodiment 1

[0037] 1. 1000 grams of industrial grade rutile titanium dioxide (purity greater than 95%, particle size distribution D50 is 0.25 microns, D 10 0.031 micron, D 90 0.84 microns) evenly spread in a refractory cordierite saggar with a size of (30cm x 20cmx 10cm), and the laying height of the titanium dioxide raw material is 5 cm.

[0038] Place the cordierite sagger in a high-temperature kiln, raise the temperature at a rate of 1-2°C / min in an air atmosphere, and raise the temperature to 950°C, and keep it warm for 1.5 hours. Then turn off the heat and let the kiln cool down naturally.

[0039] 2. When the temperature of the kiln drops below 200°C, take out the cordierite sagger with a tool. Take out the sintered titanium dioxide in the sagger. First use an alumina mortar to grind it manually, and then put about 300 grams of coarse particles into a 1L zirconia ball mill jar, use zirconia balls as the medium, and use a laboratory small-scale agitating ball mill for pulverizatio...

Embodiment 2

[0043] 1. 1000 grams of industrial grade rutile titanium dioxide (purity greater than 95%, particle size distribution D 50 0.44 microns, D 100.15 microns, D90 is 1.24 microns) evenly spread in a refractory alumina saggar with a size of (30cm x 20cm x 10cm), and the laying height of titanium dioxide raw materials is 6 cm. Place the sagger in a high temperature kiln. In the air atmosphere, the temperature was raised at a rate of 1-2°C / min, the temperature was raised to 1050°C, and the temperature was kept for 1.5 hours. Then turn off the heat and let the kiln cool down naturally.

[0044] 2. When the temperature of the kiln drops below 200°C, take out the alumina sagger with tools. Take out the sintered titanium dioxide in the sagger. First use an alumina mortar to grind it by hand, and then put about 350 grams of coarse particles into a 1L zirconia ball mill jar, use zirconia balls as the medium, and use a small laboratory stirring ball mill for pulverization. The speed of ...

Embodiment 3

[0048] 1. 1000 grams of industrial grade rutile titanium dioxide (purity greater than 95%, particle size distribution D50 is 0.25 microns, D 10 0.031 micron, D 90 0.84 micron) evenly spread in a refractory cordierite sagger with a size of (30cm x 20cm x 10cm), and the laying height of titanium dioxide raw material is 7cm.

[0049] Place this cordierite sagger in a high temperature kiln. In the air atmosphere, the temperature was raised at a rate of 1-2°C / min, and the temperature was raised to 1150°C, and kept for 1.5 hours. Then turn off the heat and let the kiln cool down naturally.

[0050] 2. When the temperature of the kiln drops below 200°C, take out the cordierite sagger with a tool. Take out the sintered titanium dioxide in the sagger. First use an alumina mortar to grind it by hand, and then put about 400 grams of coarse particles into a 1L zirconia ball mill jar, use zirconia balls as the medium, and use a laboratory small-scale agitating ball mill for pulverizati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com