Preparation method of three-layer carbon-coated composite lithium iron phosphate cathode material

A technology of lithium iron phosphate and cathode material, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of difficulty in Li+ insertion and extraction, low diffusion rate, etc., achieve uniform and dense coating effect, and improve electrical conductivity. , the effect of improving electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

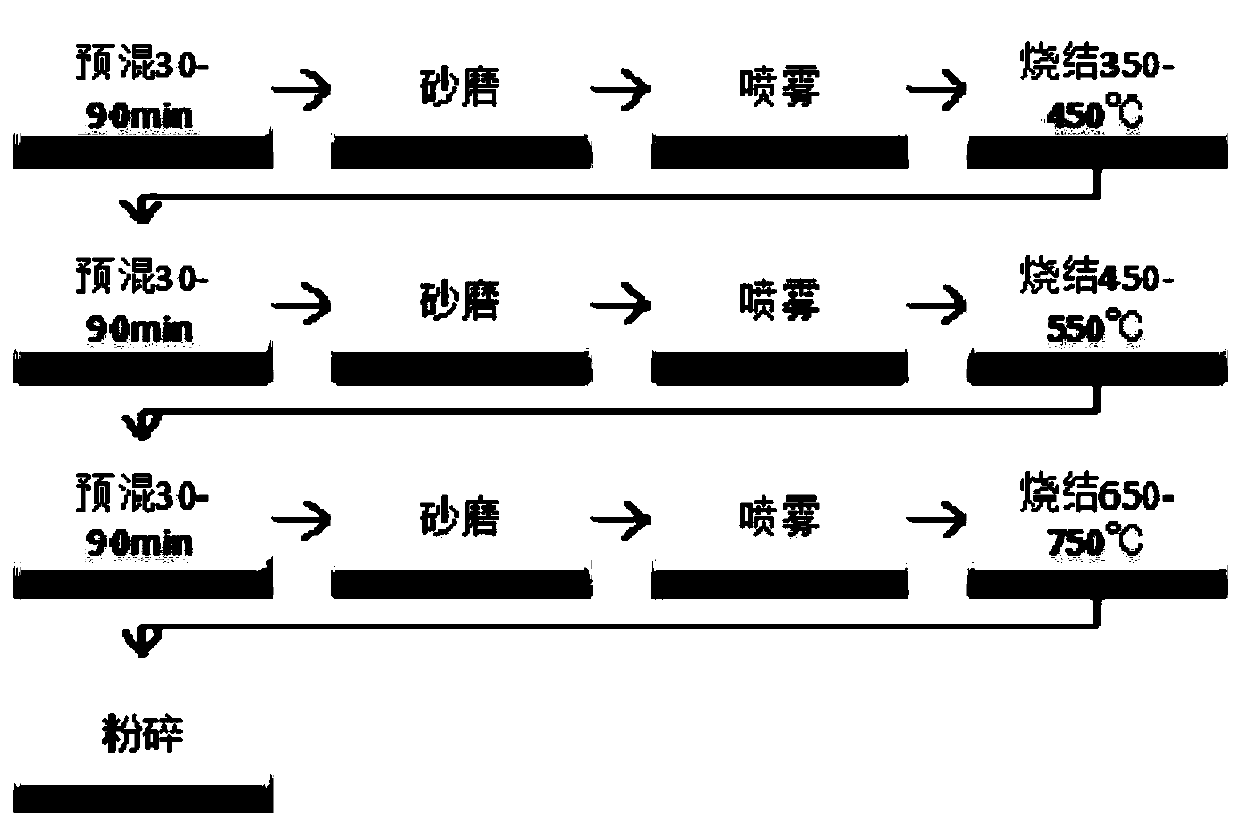

[0049] Such as figure 1 As shown, the manufacturing process of the three-layer carbon-coated composite lithium iron phosphate cathode material in this embodiment is as follows:

[0050] Take by weighing 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 400g glucose, 60g polyvinylpyrrolidone (PVP). Add 10000ml of deionized water to the stirring mill, under stirring, add FePO 4 and Li 2 CO 3 Disperse for 30min. Continue to slowly add glucose and PVP, and obtain a slurry after dispersing for 30 minutes. The above slurry was transferred into a sand mill, and the precursor slurry with an average particle size of 350 nm was obtained by sand grinding in the sand mill. The precursor slurry was transported to the spray dryer, the inlet temperature was set to 240°C, and the outlet temperature was set to 100°C to obtain the precursor powder. Place the precursor powder in a sintering furnace protected by high-purity nitrogen (volume purity 99.999%)...

Embodiment 2

[0060] Such as figure 1 As shown, the manufacturing process of the three-layer carbon-coated composite lithium iron phosphate cathode material in this embodiment is as follows:

[0061] Take by weighing 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 15g superconducting carbon black, 60g polyvinylpyrrolidone (PVP). Add 10000ml of pure water to the stirring mill, and add FePO 4 and Li 2 CO 3 Disperse for 30min. Continue to slowly add superconducting carbon black and PVP, and obtain a slurry after dispersing for 30 minutes. The above slurry was transferred into a sand mill, and the precursor slurry with an average particle size of 350 nm was obtained by sand grinding in the sand mill. The precursor slurry was transported to the spray dryer, the inlet temperature was set to 240°C, and the outlet temperature was set to 100°C to obtain the precursor powder. Place the precursor powder in a sintering furnace protected by high-purity nitrogen...

Embodiment 3

[0066] Such as figure 1 As shown, the manufacturing process of the three-layer carbon-coated composite lithium iron phosphate cathode material in this embodiment is as follows:

[0067] Take by weighing 7200g anhydrous ferric phosphate (FePO 4 ), 1818g lithium carbonate (Li 2 CO 3 ), 30gPEG, 60g polyvinylpyrrolidone (PVP). Add 10000ml of pure water to the stirring mill, and add FePO 4 and Li 2 CO 3Disperse for 30min. Continue to slowly add PEG and PVP and disperse for 30 minutes to obtain a slurry. The above slurry was transferred into a sand mill, and the precursor slurry with an average particle size of 350 nm was obtained by sand grinding in the sand mill. The precursor slurry was transported to the spray dryer, the inlet temperature was set to 240°C, and the outlet temperature was set to 100°C to obtain the precursor powder. Place the precursor powder in a sintering furnace protected by high-purity nitrogen (volume purity 99.999%), heat up to 400°C at a rate of 5°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com