Preparation method of sodium ion battery negative electrode material, negative electrode material and sodium ion battery

A technology of sodium ion battery and negative electrode material, applied in battery electrodes, negative electrodes, secondary batteries, etc., can solve problems such as potential safety hazards, poor rate performance, etc., to reduce the impact of battery performance, improve rate performance, and improve safety. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

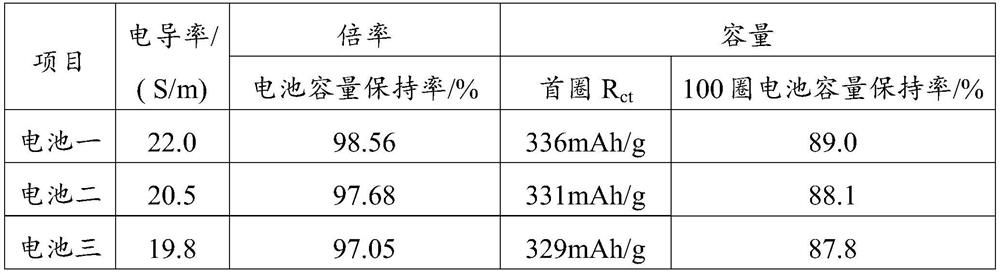

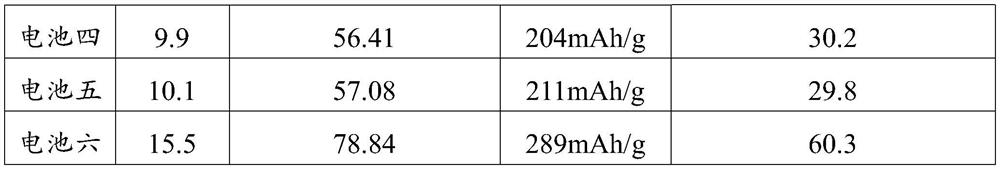

Examples

preparation example Construction

[0015] The preparation method of sodium ion battery negative electrode material of the present invention comprises:

[0016] (1) Hydrothermal reaction

[0017] Stir phenylenediamine, tannic acid and graphene oxide in water evenly, then transfer to a reaction kettle for hydrothermal reaction to obtain a compound;

[0018] (2) Carbonization reaction

[0019] The composite is carbonized in a carbonization furnace at 400-700°C.

[0020] Wherein, in step (1), the mass ratio of phenylenediamine, tannic acid and graphene oxide is 1~3:1~3:1, specifically but not limited to 1:1:1, 1:2:1 , 1:3:1, 2:1:1, 2:2:1, 4:4:3, 5:5:3, 4:5:3, 5:4:3, 2:3:1, 3 :1:1, 3:2:1, 3:3:1, preferably 5:5:3. The conditions of the hydrothermal reaction are a reaction temperature of 85-180° C. and a reaction time of 2-12 hours. Preferably, phenylenediamine, tannic acid and graphene oxide are dissolved in deionized water, stirred for 20 minutes, then transferred to a reactor for hydrothermal reaction. Compar...

Embodiment 1

[0025] The preparation method of the graphene composite material doped with N and O and carbonized comprises:

[0026] (1) Hydrothermal reaction

[0027] Stir phenylenediamine, tannic acid, and graphene oxide with a mass ratio of 5:5:3 in deionized water for 20 minutes, and then transfer to a reaction kettle for 10 hours of hydrothermal reaction at 120°C to obtain a compound;

[0028] (2) Carbonization reaction

[0029] The compound was carbonized in a carbonization furnace at 600°C.

Embodiment 2

[0031] The preparation method of the graphene composite material doped with N and O and carbonized comprises:

[0032] (1) Hydrothermal reaction

[0033] Stir the phenylenediamine, tannic acid, and graphene oxide with a mass ratio of 1:1:1 in deionized water for 20 minutes, and then transfer it to a reaction kettle for 6 hours of hydrothermal reaction at 150° C. to obtain a compound;

[0034] (2) Carbonization reaction

[0035] The composite was carbonized in a carbonization furnace at 500°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com