Shunting type multi-pipe pulse detonation combustion chamber

A technology of pulse detonation and combustion chamber, applied in the direction of combustion chamber, continuous combustion chamber, combustion method, etc., can solve the problems of turbine blade erosion, turbine impact, etc., to reduce impact and thermal erosion, and reduce pulsation , increase the effect of mixing time and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

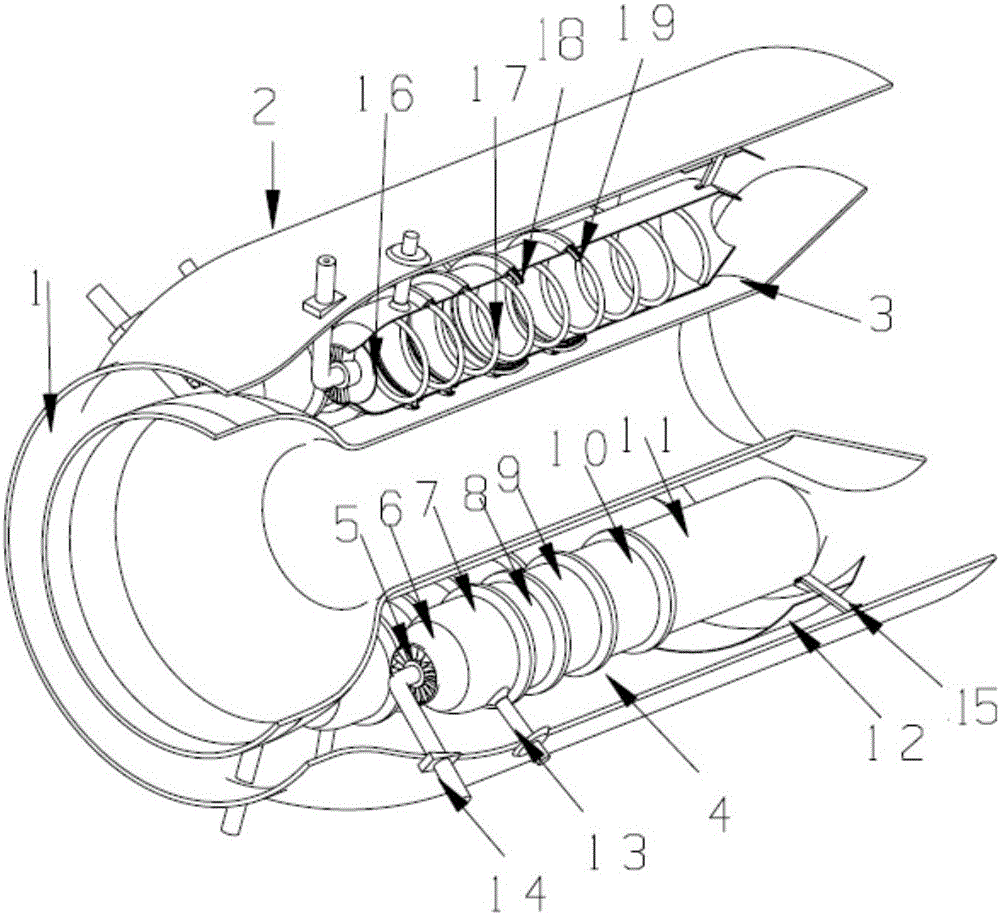

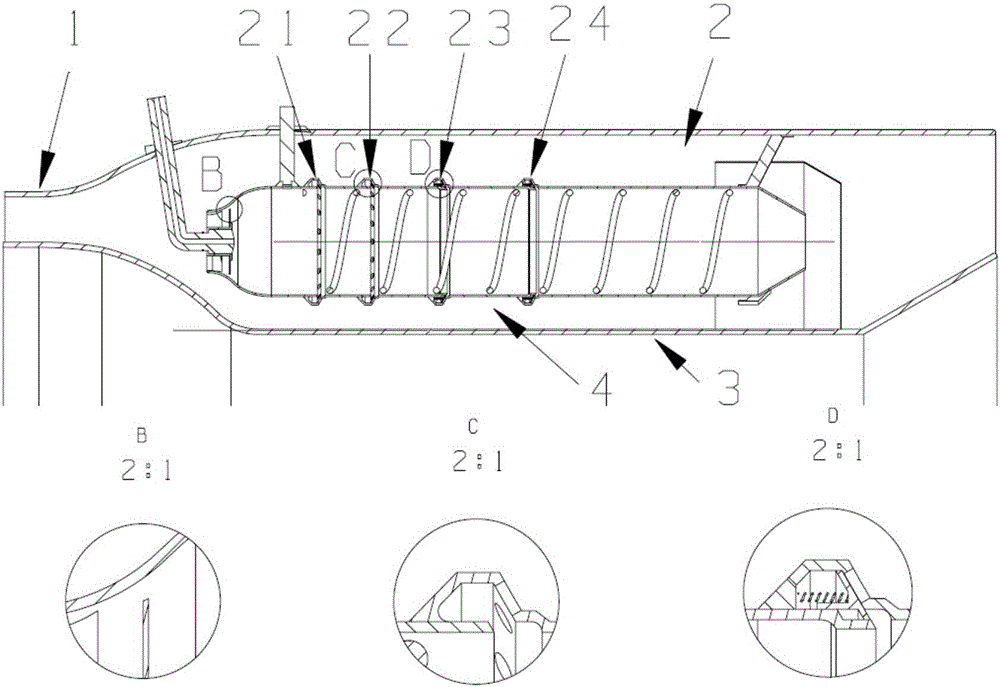

[0021] A split multi-tube pulse detonation combustion chamber described in this embodiment is as follows: figure 1 As shown, it includes a pre-diffuser 1 of the combustion chamber, a casing 2 outside the combustion chamber, a casing 3 inside the combustion chamber, a fuel nozzle 14 , a spark plug, a circular detonation tube 4 and a guide ring 12 . The six detonation tubes are distributed in a ring, and the central angle of the central axis of the two adjacent detonation tubes is 60°. The detonation tube 4 is fixed outside the combustion chamber through the fuel supply seat, the ignition mounting seat 13 and the guide ring fin 15 on the receiver. Outside the combustion chamber, the inner and outer casings 2 and 3 are connected by the turbine guide vane and the compressor diffuser vane. The guide ring 12 is a ring of flakes to stabilize the detonation gas and reduce the mixing loss. The ignition installation The seat is used to install the spark plug mouth. The detonation tube...

Embodiment approach 2

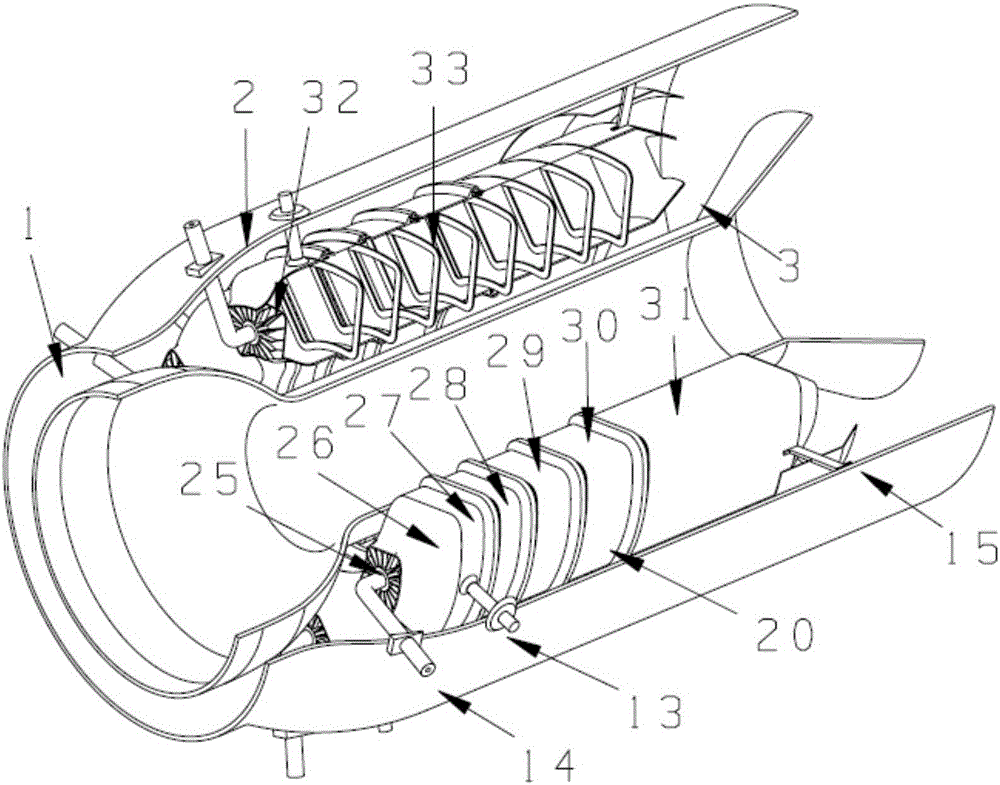

[0024] As a second embodiment of the present invention, see figure 2 , the circular detonation tube 4 is replaced by a fan-shaped detonation tube 20 . The corresponding central angle of the fan-shaped detonation tube 20 is 45°, the radius of the inner arc is 1.25 times the radius of the casing 3 inside the combustion chamber, and the radius of the outer arc is 7 / 8 of the casing 2 outside the combustion chamber. The ignition seat is on the outer arc of the ignition section. Sector-shaped detonation tube 20 is made up of head sector-shaped air intake section 26, sector-shaped ignition section 27, sector-shaped detonation section a28, sector-shaped detonation section b29, sector-shaped detonation section c30, and sector-shaped detonation section d31. The valve plate 32 used on the fan-shaped detonation tube 20 is also fan-shaped, and the detonation enhancement device is changed to a fan-shaped obstacle 33, and the working mode of the fan-shaped detonation tube is the same as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com