Process for producing powdered milk comprising multiple resistance nutrition immune optimization system

A production process and technology of milk powder, which is applied in the field of production process of milk powder containing multi-resistance nutrition and immune optimization system, can solve the problems such as failure to maintain nucleotide biological activity and component structure, uneven addition, and fishy smell, etc. The ability of the intestine to resist viruses, improve the intestinal flora, and ensure the effect of product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

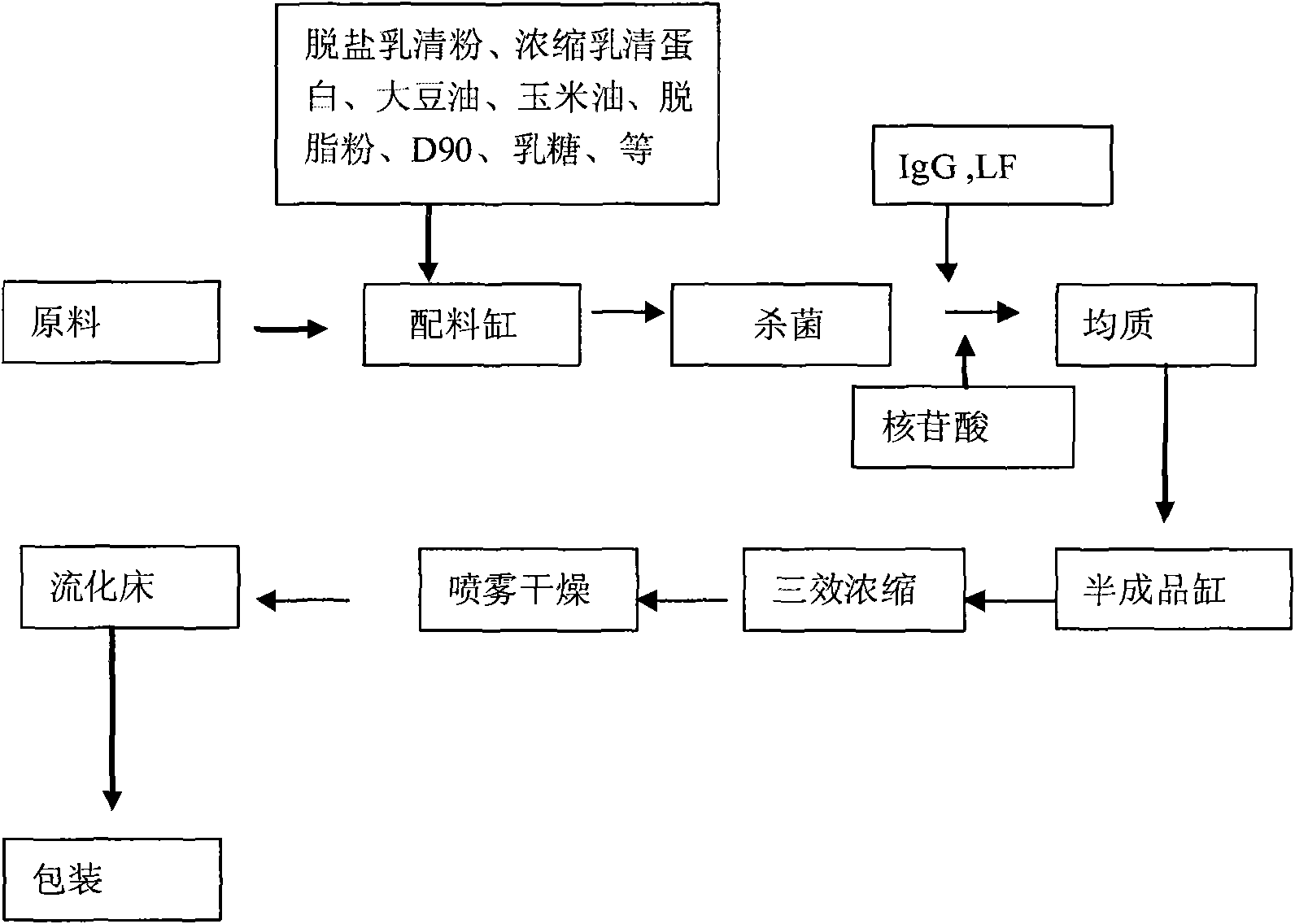

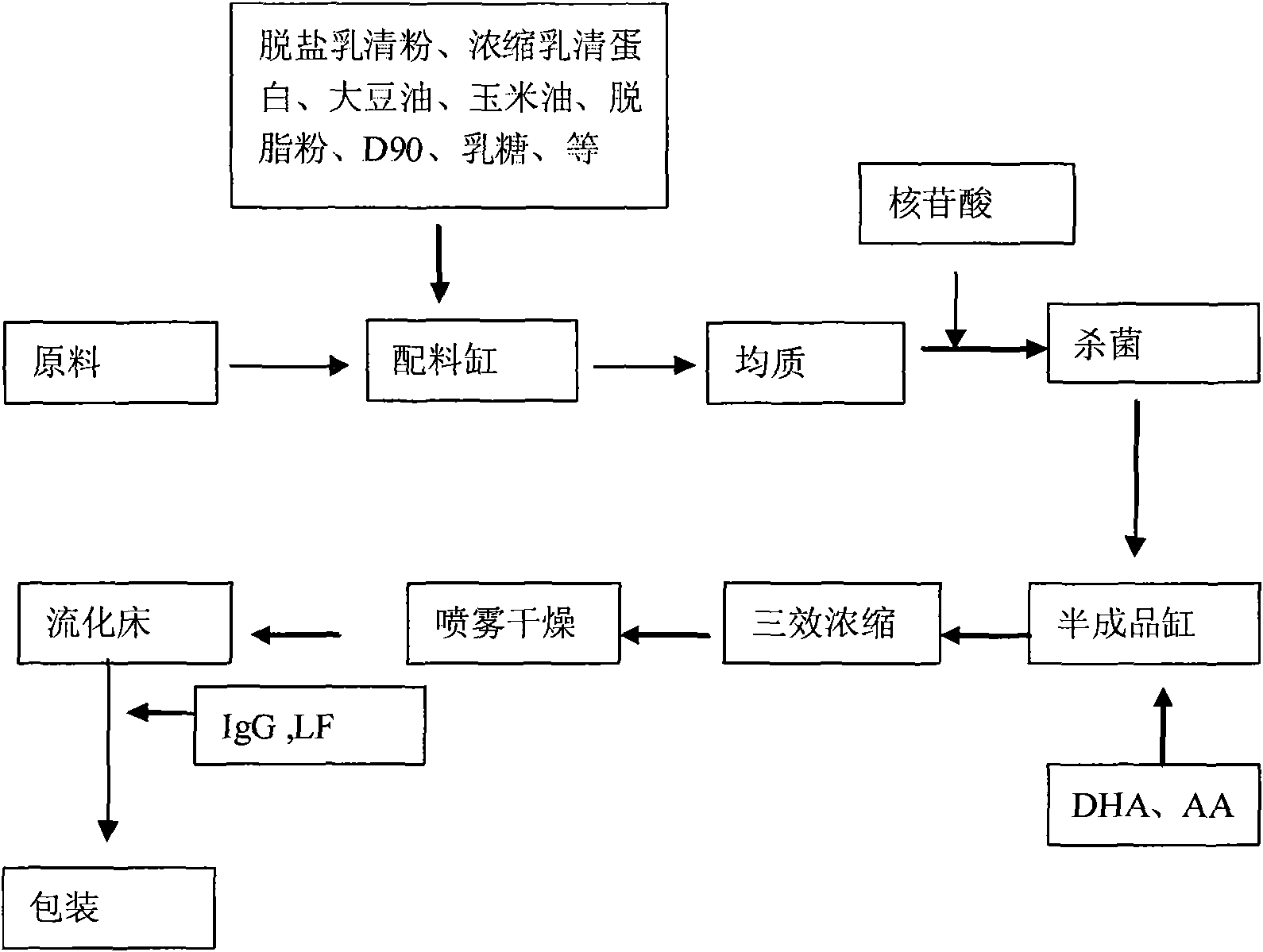

[0055] A production process of milk powder containing multi-resistance nutritional immune optimization system of the present invention mainly includes the following steps:

[0056] (1) Pretreatment of raw milk, including: acceptance of raw milk, filtration and centrifugal purification, pre-sterilization at 50-65°C, cooling to 0-4°C for storage.

[0057] (2) Preparation of docosahexaenoic acid and arachidonic acid mixed solution: DHA and ARA are dissolved in water at 25-50°C. What the present invention uses are obtained from microalgae and microencapsulated DHA, Add ARA, DHA, and ARA at the semi-finished tank, and stir for 45-60 minutes at the same time to ensure the uniformity of DHA and AA. Delay oxidation, and basically eliminate fishy smell.

[0058] (3) Mixed ingredients: take Kg fresh milk as an example, preferably, add:

[0059] Fresh cow (goat) milk 1500~3000kg

[0060] Desalted whey powder 1050~3500kg

[0061] Soybean oil 60~260kg

[0062] Corn oil 60~200kg

[00...

specific Embodiment approach 2

1 set

[0117] The products of the above two embodiments are respectively suitable for infants of 0-12 months and 6-36 months.

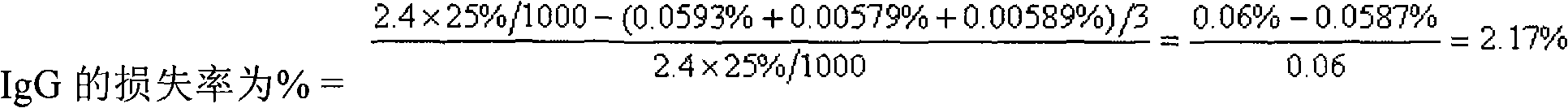

[0118] The present invention aims at the characteristics of physiological and nutritional functions of Chinese infants and young children, and the important functional biologically active nutrients are made to exert the greatest biological effect through advanced technology, scientific proportioning and mutual cooperation. Immune protein G and lactoferrin (LF) are added at the fluidized bed, and added after increasing the amount without sterilization, homogenization and spraying, which not only ensures the biological activity of immune protein G and lactoferrin (LF), but also The quality of the product is guaranteed. The addition of fructo-oligosaccharides (FOS) and galacto-oligosaccharides (GOS) improves the intestinal flora, inhibits the growth of harmful products and pathogenic bacteria in the intestinal tract, thereby ensuring the abilit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com