Collagen protein and collagen polypeptides, preparation thereof and applications

A collagen and collagen polypeptide technology, which is applied in the fields of peptide/protein components, animal/human proteins, specific peptides, etc., to achieve the effects of considerable economic benefits, low cost, and simple process equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

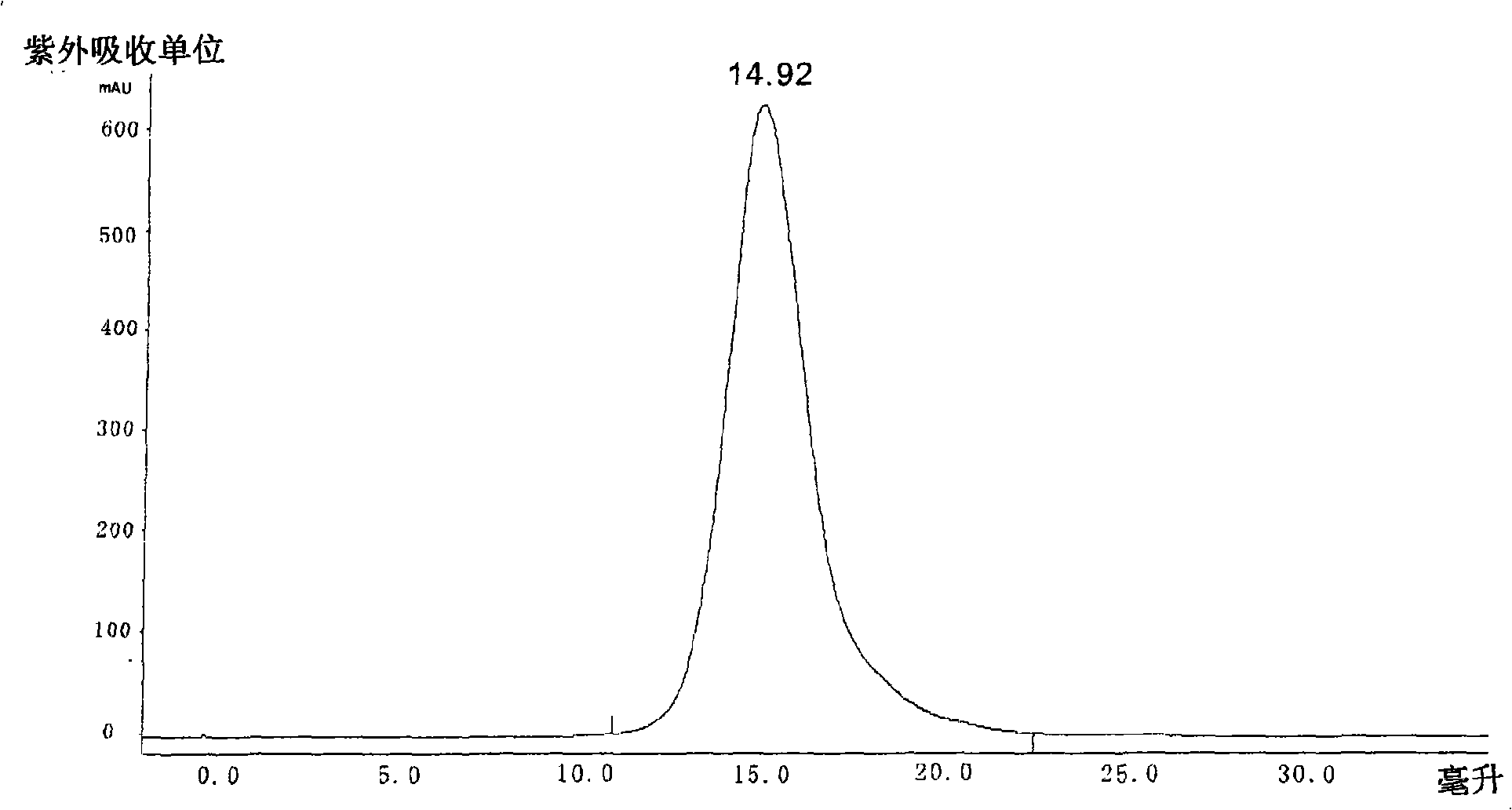

[0044] Example 1 Preparation of Collagen and Polypeptide Using Tilapia Scale as Raw Material

[0045] Wash 100 grams of decalcified tilapia scales with water, add deionized water at 1000°C and heat up to 85°C for 30 minutes, then cool down to 45°C, adjust the pH value to 8.0, add 3 grams of alkaline protease, degrade for 2 hours, and then re-degrade under the same conditions Add 4 grams of neutral protease, react for 2 hours, the scales are all dissolved, then raise the temperature to 90°C, keep warm for 15 to 30 minutes to inactivate the enzyme, add an appropriate amount of flocculant diatomite and activated carbon (mixed at 1:1) to settle for 8 Take the supernatant directly; the supernatant is distilled under reduced pressure at a vacuum degree of 0.06-0.10Mpa and a temperature of 40-65°C, and finally spray-dried to obtain solid protein polypeptide powder.

[0046] After determination, among them: Hydroxyproline content: 9.4%; Hydroxylysine, 1.4%.

Embodiment 2

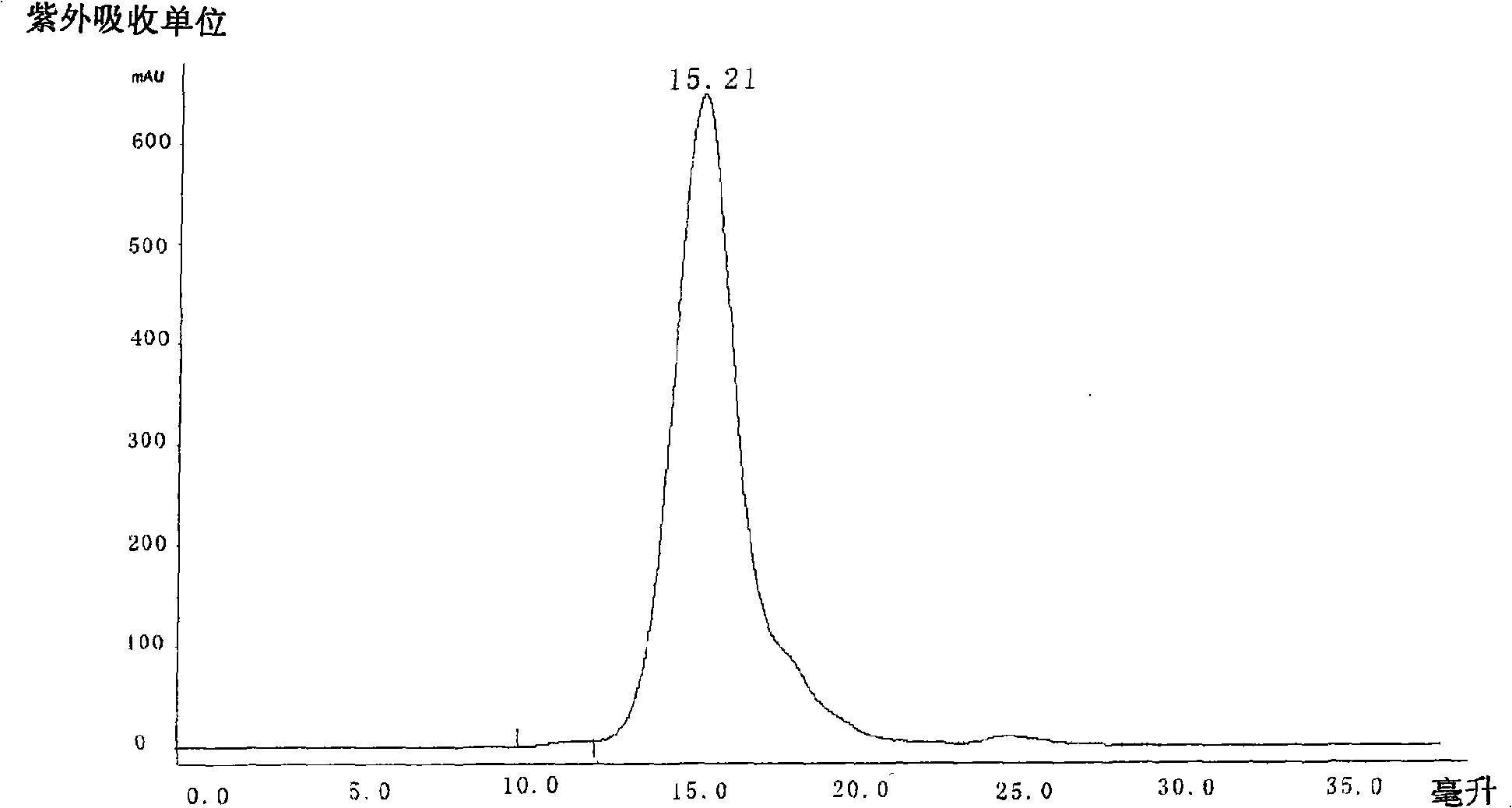

[0047] Example 2 Preparation of Collagen and Polypeptide Using Tilapia Skin as Raw Material

[0048] Weigh 100g of dried fish skin into a 1000ml beaker, wash at room temperature until the pH value is about 7, heat to 80°C for 30 minutes, cool to 50°C, adjust the pH value to 8, add 2.5 grams of alkaline protease, and react for 3 hours ; Adjust the temperature to 45°C, add 4 grams of neutral protease, and stir at a constant temperature for 3 hours; heat to 85°C for 15 minutes to inactivate the enzyme. Add an appropriate amount of flocculant diatomaceous earth and activated carbon (mixed at 1:2) to settle for 8 hours, and take the supernatant directly. The supernatant is distilled under reduced pressure at a vacuum degree of 0.06-0.10Mpa and a temperature of 40-65°C, and finally spray-dried to obtain solid protein polypeptide powder.

[0049] Product testing results: Hydroxyproline content: 9.38%; Hydroxylysine, 1.31%.

Embodiment 3

[0050] Example 3 Preparation of Collagen and Polypeptides Using Cod Skin as a Raw Material

[0051] Weigh 100g of dried cod skin into a 1000ml beaker, wash at room temperature until the pH value is about 7, heat to 80°C for 30 minutes, cool to 50°C, adjust the pH value to 8, add 4 grams of trypsin respectively, and react 6 Hours; adjust the temperature to 45°C, add 3 grams of 1398 protease, and stir at a constant temperature for 5 hours; heat to 85°C for 15 minutes to inactivate the enzyme.

[0052] After flocculation and precipitation filtration, the filtrate is distilled under reduced pressure at about 50°C, and finally spray-dried to obtain fish skin collagen polypeptide powder.

[0053] Product testing results: Hydroxyproline content: 7.3%; Hydroxylysine, 1.3%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com