Synthesis method of single-ended unsaturated polyethylene glycol compound

A polyethylene glycol and synthesis method technology, applied in the field of organic synthesis, can solve problems such as danger, high requirements for storage conditions, and high requirements for experimental equipment, and achieve the effects of reducing equipment requirements, reducing production costs, and improving product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

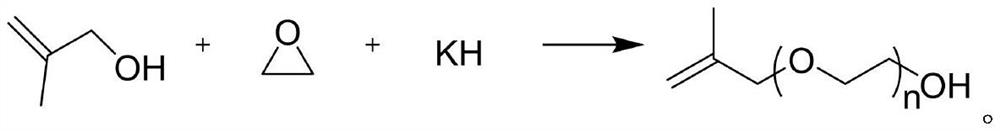

Image

Examples

Embodiment 1

[0029] Embodiment 1: take potassium hydride, potassium hydroxide as initiator

[0030] Add 50mL of anhydrous tetrahydrofuran to the reactor, add 1.78g of potassium hydride and 1g of potassium hydroxide, close the reactor, fill the reactor with nitrogen to pressurize, then vacuumize and then fill with nitrogen; open the vent valve, and then open the feed valve, add 1.17g of 2-methallyl alcohol, close the feed valve, then close the vent valve, turn on the stirring, set the temperature at 40°C, react for four hours, turn off the stirring, heat, and cool the reactor with liquid nitrogen To minus 20°C, vacuumize and then fill with nitrogen, repeat this three times; open the vent valve, then open the feed valve, carefully add ethylene oxide (100mL) and quickly close the feed valve and vent valve, put Set the temperature at 45°C and react for three days. After the reaction time is up, evaporate the solvent to dryness; add 100 mL of 0.5 mol / L hydrochloric acid solution and stir for 30...

Embodiment 2

[0034] With sodium hydride and potassium hydroxide as initiators, the chemical equation is as follows:

[0035]

[0036] Add 50mL of anhydrous tetrahydrofuran to the reactor, add 2.61g of sodium hydride and 1g of potassium hydroxide, close the reactor, pressurize the reactor with nitrogen, then vacuumize and then fill with nitrogen; open the vent valve, and then open the feed valve, add 1.71g of 2-methallyl alcohol, close the feed valve, then close the release valve, turn on the stirring, and set the temperature to 40°C. React for four hours, turn off stirring and heating, cool the reactor to minus 20°C with liquid nitrogen, vacuumize and then fill with nitrogen, repeat this three times; open the vent valve, then open the feed valve, and carefully add ethylene oxide After alkane (100mL), quickly close the feed valve and vent valve, set the temperature to 45°C and react for three days, after the reaction time is up, evaporate the solvent to dryness; add 0.5mol / L hydrochloric...

Embodiment 3

[0039] Embodiment 3: take sodium hydride, potassium hydroxide as initiator

[0040]50 mL of anhydrous tetrahydrofuran was added to the reactor, and 1.06 g of sodium hydride and 1 g of potassium hydroxide were added. Close the reactor, pressurize the reactor with nitrogen and then evacuate and then fill with nitrogen; open the vent valve, then open the feed valve, add 2.91g of 2-methallyl alcohol, close the feed valve, and then close the discharge valve. Air valve, open the stirring, set the temperature at 40°C, react for four hours, turn off the stirring, heat, cool the reactor to minus 20°C with liquid nitrogen, and then fill it with nitrogen after vacuuming, repeat this three times; open the vent valve , and then open the feed valve, carefully add ethylene oxide (100mL) and quickly close the feed valve and vent valve, set the temperature to 45°C and react for three days, after the reaction time is reached, evaporate the solvent to dryness; add 100 mL of 0.5 mol / L hydrochlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com