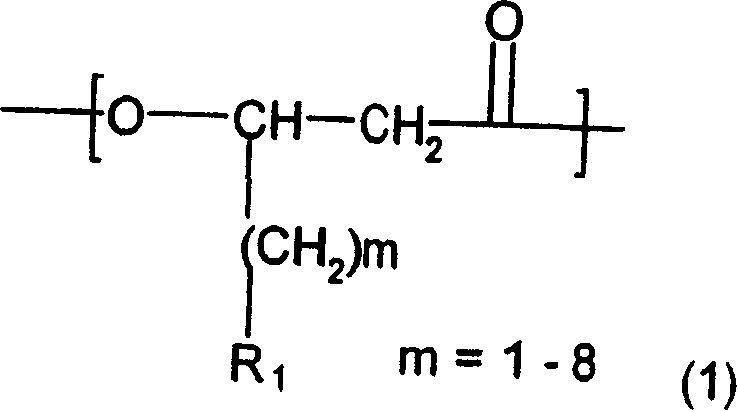

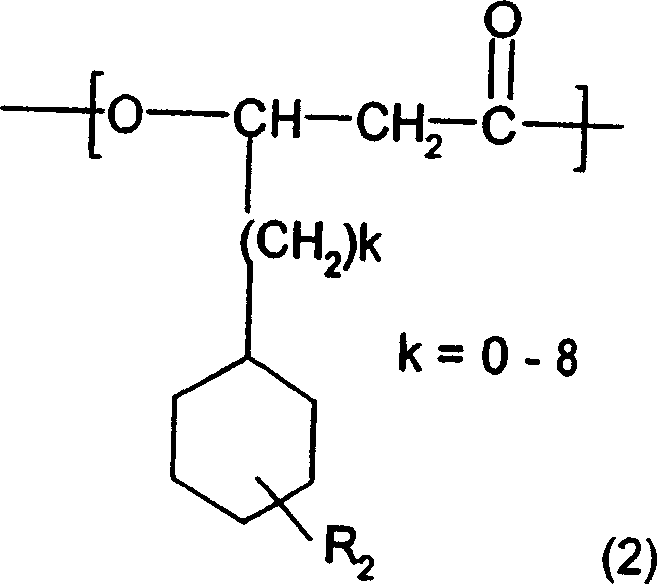

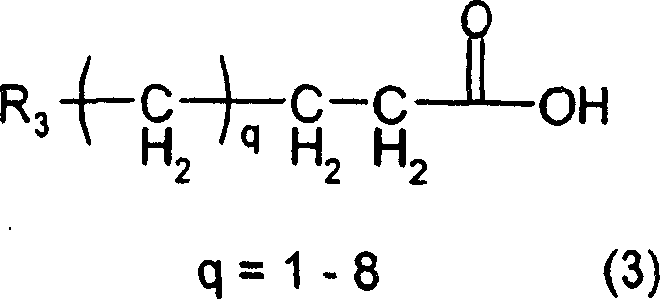

Molecular weight control method of poly hydroxy alkane acid ester

A technology of polyhydroxyalkanoate and molecule, which is applied in the field of molecular weight control of polyhydroxyalkanoate, and can solve the problems that have not been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0124] [Example 1] Controlling the molecular weight of poly 3-hydroxyl-5-phenylvaleric acid (PHPV) with polyethylene glycol-1

[0125] Containing polypeptone (Wako Pure Chemical Industries) 0.5% (W / V), 5-phenylvaleric acid 0.1% (W / V) and molecular weight control agent polyethylene glycol 200 (PEG200: average molecular weight 190-210; Kishida Chemical 0%, 1%, 2%, 5% (V / V) M9 medium 200ml, add the culture of the Pseudomonascichorii YN2 bacterium that has been shaken at 30 ℃ for 8 hours with the M9 medium containing polyptone 0.5% in advance Incubate 1 mL of the solution in a 500-mL shaking flask at 30°C for 24 hours. After culturing, the cells were obtained by centrifugation, washed with methanol, and freeze-dried. After weighing the dried cells, chloroform was added, and the mixture was stirred at 50° C. for 24 hours to extract the polymer. The chloroform from which the polymer was extracted was filtered, concentrated by an evaporator, and the part solidified by precipitation...

Embodiment 2

[0132] [Example 2] Controlling the molecular weight of PHPV with polyethylene glycol-2

[0133] As a molecular weight control agent, except having used PEG600 (average molecular weight: 570-630) instead of PEG200, it experimented by the method similar to Example 1. use 1 The structure of the obtained polymer analyzed by H-NMR was the same as in Example 1, and it was roughly a PHPV homopolymer. Table 2 shows the weights of the obtained bacterial cells and polymers, the weight ratio of polymers to bacterial cells, the molecular weights and molecular weight distributions of the obtained polymers.

[0134] PEG600(%)

[0135] CDW: cell dry weight; PDW: polymer dry weight; P / C: PDW / CDW; Mn: number average molecular weight; Mw / Mn: molecular weight distribution

Embodiment 3

[0136] [Example 3] Controlling the molecular weight of PHPV with polyethylene glycol-3

[0137] As a molecular weight control agent, except having used PEG2000 (average molecular weight: 1800-2200) instead of PEG200, it experimented by the method similar to Example 1. use 1 The structure of the obtained polymer analyzed by H-NMR was the same as in Example 1, and it was roughly a PHPV homopolymer. Table 3 shows the weights of the obtained bacterial cells and polymers, the weight ratio of polymers to bacterial cells, the molecular weights and molecular weight distributions of the obtained polymers.

[0138] PEG2000(%)

[0139] CDW: cell dry weight; PDW: polymer dry weight; P / C: PDW / CDW; Mn: number average molecular weight; Mw / Mn: molecular weight distribution

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com