Catalytic system for catalyzing the polymerization of polar vinyl monomers

A technology of vinyl monomer and catalytic system, applied in the field of catalytic system, can solve the problems of increasing the cost of catalytic system, unable to obtain unsaturated vinyl polymer, etc., and achieve the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

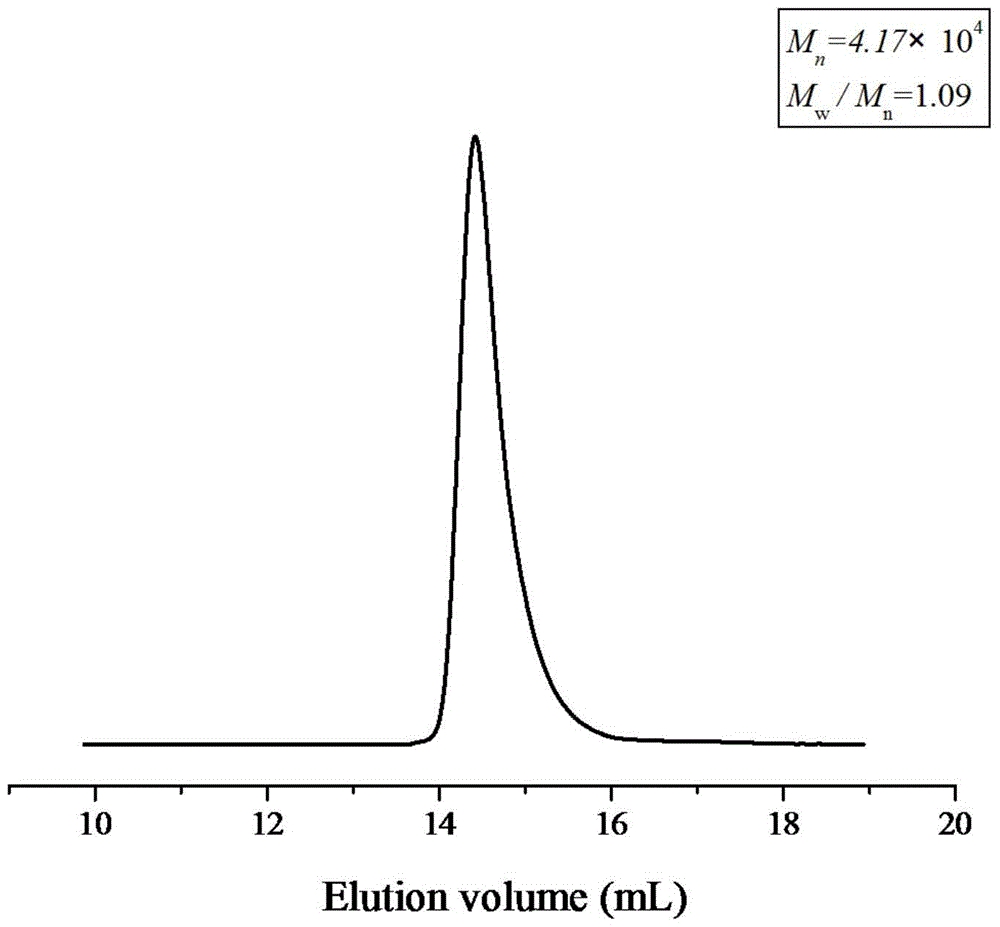

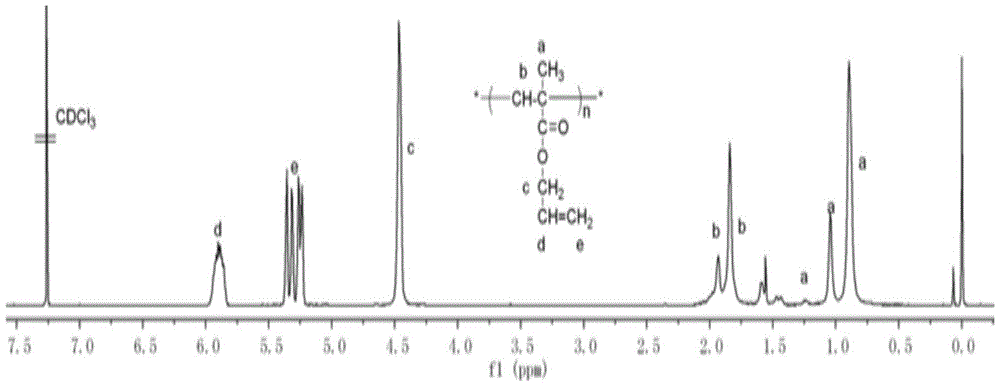

Examples

Embodiment 1

[0025] In a 20 ml reaction flask with a stirring bar, 11.6 mg of triethylsilane (Et 3 SiH), 1.0 g of methyl methacrylate, 5 ml of fluorobenzene, stirred for 5 minutes, then added 88.3 mg of [Et 3 Si][B(C 6 f 5 ) 4 ]·C 7 h 8 Polymerization begins. The reaction was carried out at 20°C for 1 hour. After the reaction was completed, 2 drops of methanol solution containing 10% hydrochloric acid were added to terminate the reaction. The polymer was poured into 200 ml of methanol (containing 10% hydrochloric acid), and stirred for 1 hour. The polymer was collected by filtration, washed three times with 20 ml of methanol each time, and then dried in a vacuum oven at 50° C. to constant weight to obtain 1.0 g of polymer with a yield of 100%. Gel chromatography analysis gained polymethyl methacrylate M n = 10400, PDI = 1.10.

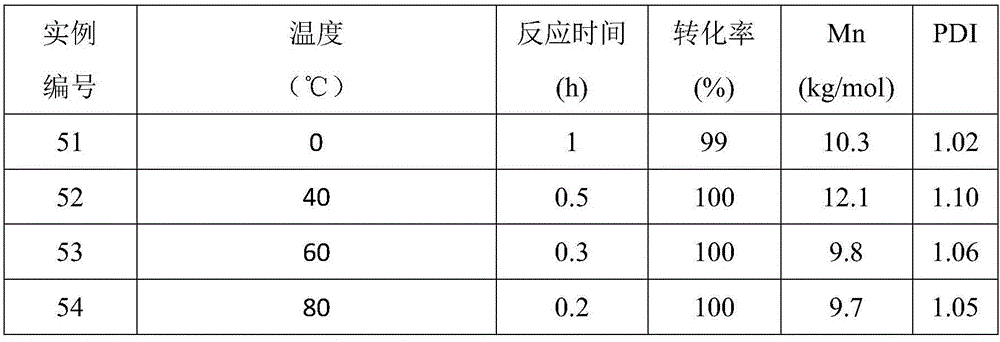

[0026] See Table 1-5 for other application examples

[0027] Table 1 Application examples of different initiators

[0028]

[0029]

[0030] * No...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com