Technology for preparing small-aperture aluminum foam without viscous melt foaming method

A technology of melt foaming and aluminum foam, which is applied in the field of preparation of porous metal materials, can solve the problems of high pyrolysis speed of titanium hydride, increase of foam aluminum preparation cost, easy floating, breaking or merging, etc., to promote production and The effect of spreading, increasing viscosity, and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

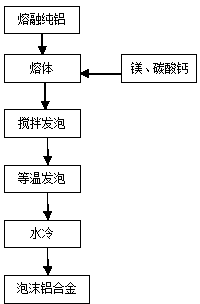

Method used

Image

Examples

Embodiment approach 1

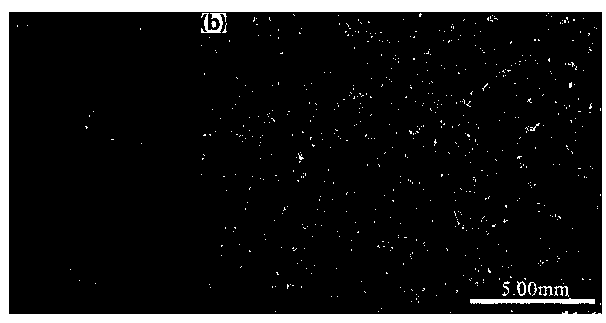

[0019] Embodiment 1: Industrial pure aluminum is heated to 700°C in a stainless steel crucible o C is melted, and the oxide film on the surface of the melt is removed after holding for 10 minutes; then CaCO is added to the aluminum melt 3 The metal magnesium block with 2 times the molar weight was stirred for 5 minutes at a speed of 400rpm after 10 minutes; the temperature of the melt was raised to 710 o C, then add calcium carbonate with a mass of 1.8% of the matrix into the melt and stir at a speed of 1000rpm for 35 seconds, heat and foam for 60s, take out the crucible and water-cool it, and obtain aluminum foam with an average pore diameter of 2.0mm, a porosity of 80%, and a uniform pore structure .

Embodiment approach 2

[0020] Embodiment 2: Heating industrial pure aluminum to 700°C in a stainless steel crucible o C is melted, and the oxide film on the surface of the melt is removed after holding the heat for 10 minutes; adjust the temperature to 680 o C, then add CaCO to the aluminum melt 3 The metal magnesium block with 2 times the molar weight was stirred for 5 minutes at a speed of 400rpm after 10 minutes; the melt temperature was adjusted to 670 o C, then add calcium carbonate with a mass of 1.5% of the matrix to the melt and stir at a speed of 1000rpm for 50 seconds, heat and foam for 30s, take out the crucible and water-cool it, and obtain an aluminum foam with an average pore diameter of 1.0mm, a porosity of 60%, and a uniform pore structure .

Embodiment approach 3

[0021] Embodiment 3: Heating industrial pure aluminum to 700°C in a stainless steel crucible o C melting, heat preservation 10min, remove the oxide film on the surface of the melt; adjust the temperature to 690 o C, the CaCO 3 A pure magnesium block with 3 times the molar weight is added to the melt, and after 10 minutes, it is stirred at a speed of 400rpm for 5 minutes; the temperature of the melt is raised to 700 o C, then add calcium carbonate with a mass of 1.5% of the matrix to the melt and stir at a speed of 1000rpm for 40 seconds, heat and foam for 90 seconds, take out the crucible for water cooling, and obtain a foam with an average pore diameter of 1.5mm, a porosity of 70%, and a uniform pore structure aluminum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com