Antifreeze anticorrosion durable concrete and preparation method thereof

A durable concrete and anti-corrosion technology, applied in the field of concrete, can solve the problems of unstable quality, difficult supply of cement, and inability to meet the construction period, and achieve the effects of improving project quality, reducing usage, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of frost-resistant and corrosion-resistant durable concrete, the concrete is composed of the following components according to parts by weight (kg): ordinary Portland P.O 42.5 cement 280, A powder 220, medium sand 700 with a fineness modulus of 2.8, and a particle size of 5 -32.5mm, continuously graded gravel 1050, water 164, water reducer 10.56;

[0036] The A powder is composed of the following components in parts by weight (kg): 71.5 parts by weight of slag, 49.5 parts by zeolite rock, 77 parts by fly ash, 11 parts by weight of feldspar, and 11 parts by quicklime.

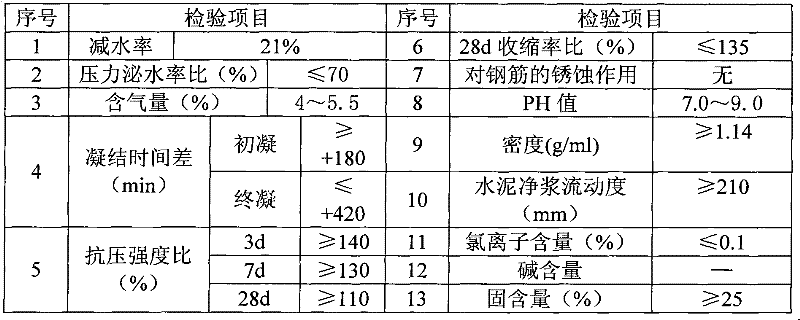

[0037] The water-reducing agent is a composite of aliphatic water-reducing agent and sulfamic acid-based water-reducing agent. It is a commercially available product from Weifang Dayuan Industrial Co., Ltd., and its technical indicators are shown in Table 1.

[0038] The preparation method of the described frost-resistant and corrosion-resistant durable concrete comprises the following steps:

[0...

Embodiment 2

[0046] A kind of frost-resistant and corrosion-resistant durable concrete, the concrete is composed of the following components according to parts by weight (kg): ordinary Portland P.O 42.5 cement 270, A powder 230, medium sand 705 with a fineness modulus of 2.8, and a particle size of 5 -32.5mm, continuously graded gravel 1050, water 164, water reducer 15;

[0047] The A powder is composed of the following parts by weight (kg): slag 80.5, zeolite 57.5, fly ash 80.5, celestite 11.5.

[0048] The water reducer is a composite of aliphatic water reducer and sulfamate-based water reducer, and its technical indicators are shown in Table 1.

[0049] The preparation method of the described frost-resistant and corrosion-resistant durable concrete comprises the following steps:

[0050] (1) Weigh the raw materials of each component of powder A in proportion, pulverize them with an ultrafine mill, and mix them evenly. The specific surface area of powder A is 600m 2 / kg;

[0051] (2...

Embodiment 3

[0055] A kind of anti-freezing and anti-corrosion durable concrete, according to the weight part (kg), the concrete is composed of the following components: ordinary Portland P.O 42.5 cement 280, A powder 220, medium sand 715 with a fineness modulus of 2.8, and a particle size of 5 -32.5mm, continuously graded gravel 1050, water 164, water reducer 18;

[0056] The A powder is composed of the following components in parts by weight (kg): slag 66, zeolite rock 44, fly ash 77, feldspar 22, quicklime 11.

[0057] The water reducer is a composite of aliphatic water reducer and sulfamate-based water reducer, and its technical indicators are shown in Table 1.

[0058] The preparation method of the described frost-resistant and corrosion-resistant durable concrete comprises the following steps:

[0059] (1) Weigh the raw materials of each component of powder A in proportion, pulverize them with an ultrafine mill, and mix them evenly. The specific surface area of powder A is 800m 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com