Foam generator for preventing and extinguishing fire in coal mine

A foam generator, anti-fire technology, applied in the direction of fire prevention, dust prevention, mining equipment, etc., can solve the problems of affecting the foaming effect, complex manufacturing process, blockage, etc., to prolong the mixing time and compact structure Reasonable, not easy to block the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

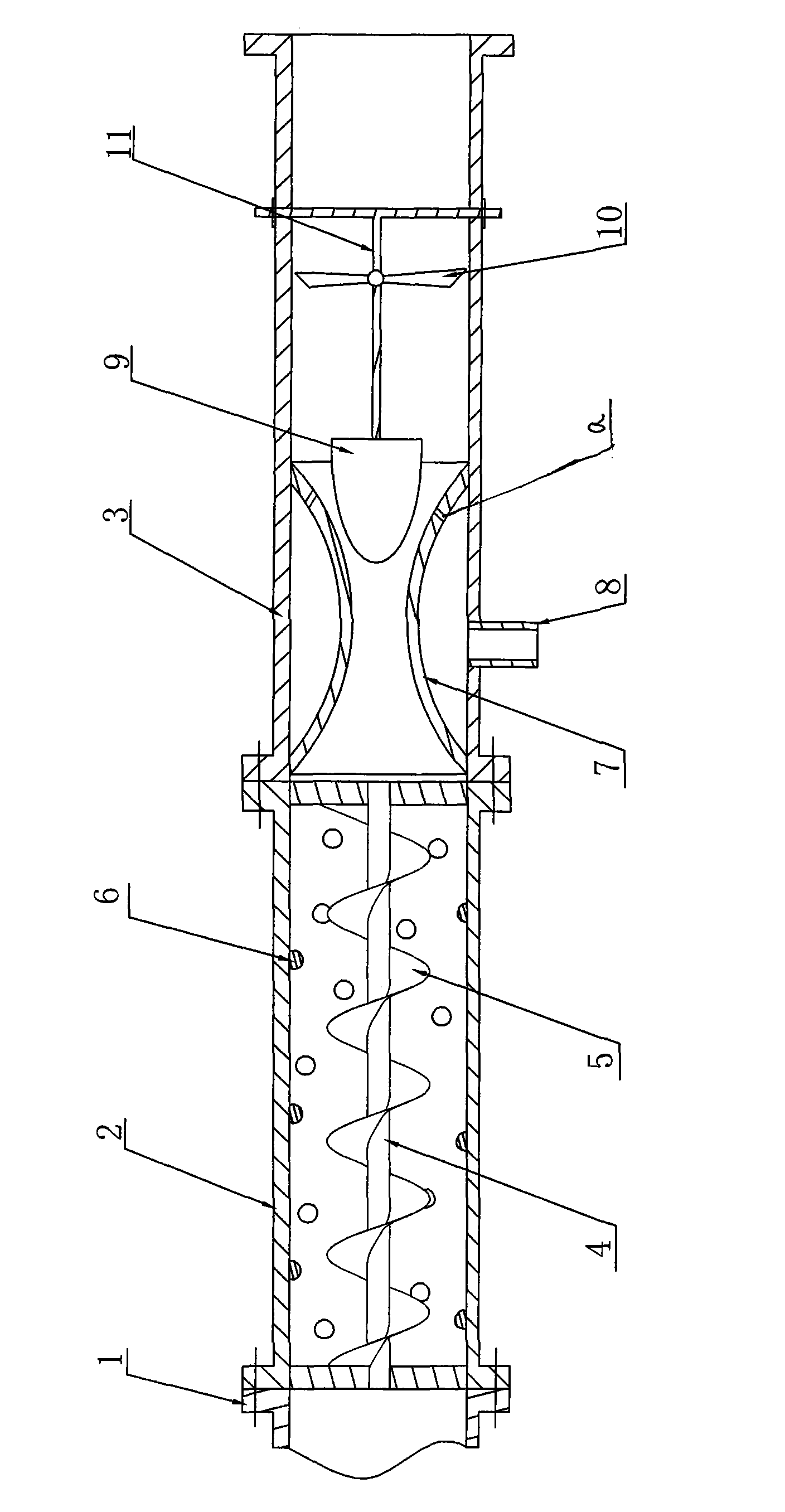

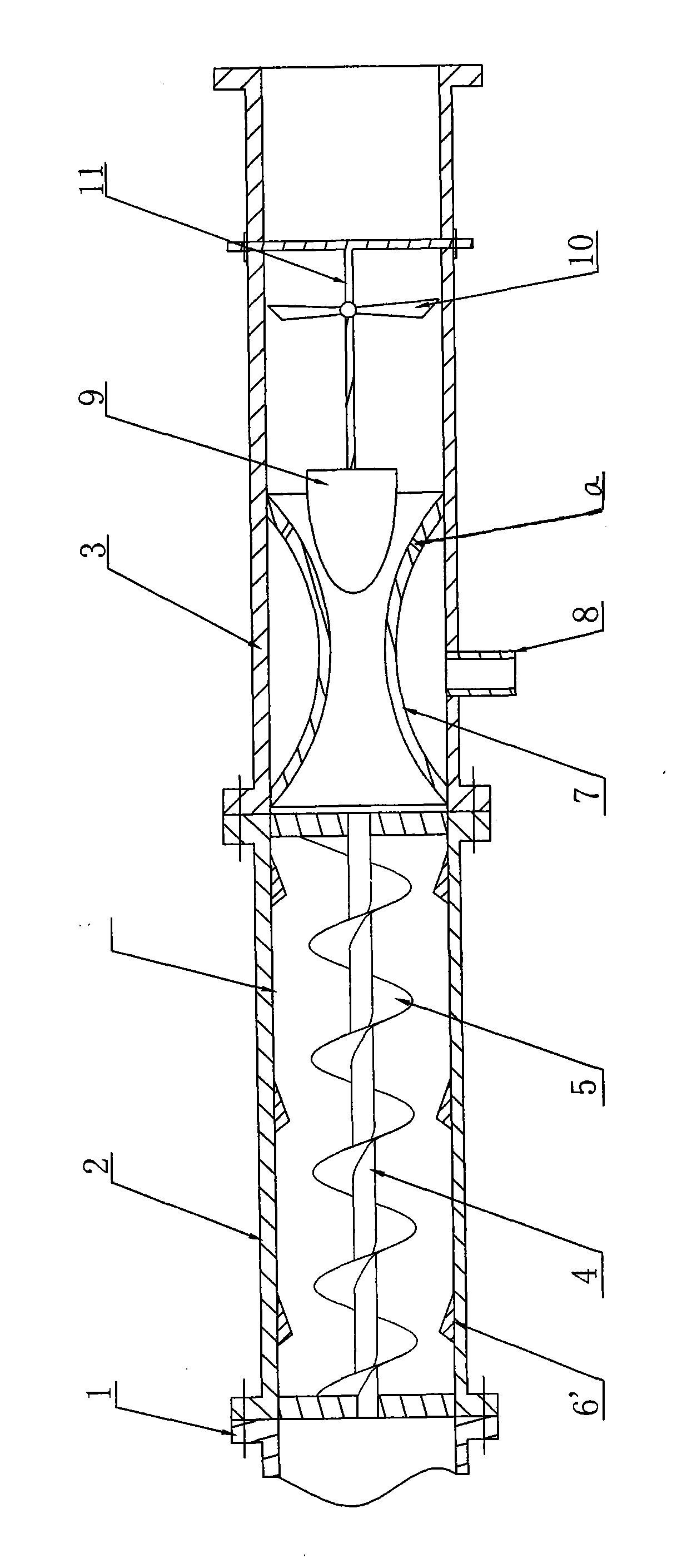

[0020] Such as figure 1 As shown, the foam generator used for coal mine fire prevention and extinguishing of the present invention includes a feed pipe 1, a mixer 2, a foamer cylinder 3, a mixer shaft 4, a stirring blade 5, a raised portion 6, and a Venturi tube 7. Gas inlet pipe 8, collector 9, impeller 10 and fixed rod 11. For convenience of description, the inlet end of the feed pipe 1 is defined as the front.

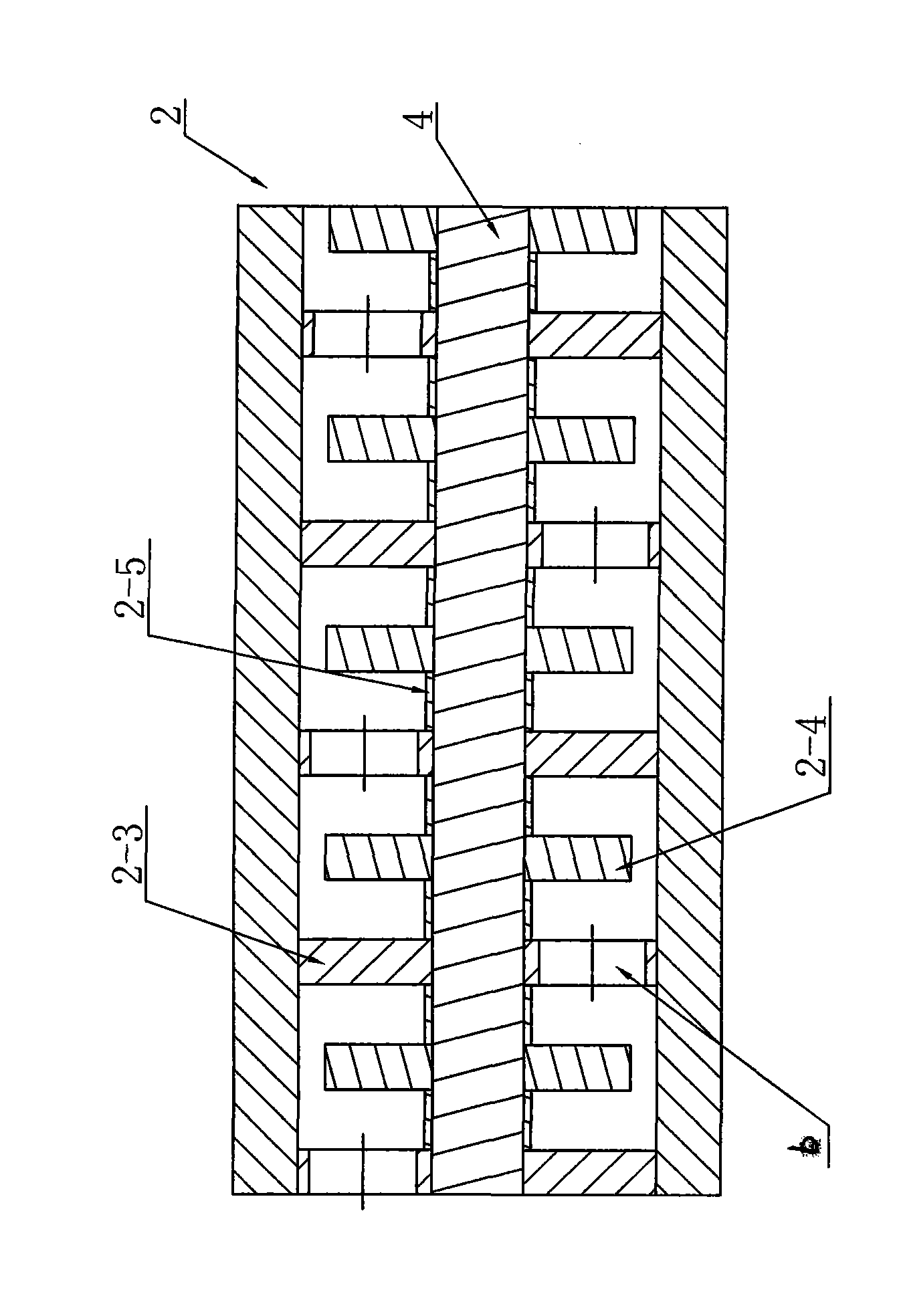

[0021] The feed pipe 1 is connected with the mixer 2 through threaded fasteners, and the yellow mud or fly ash slurry and the foaming agent mixture are transported from the feed pipe 1 to the foam generator used for fire prevention and extinguishing in coal mines. Its axis is equipped with a mixer shaft 4, the mixer shaft 4 is installed in the mixer 2 through a bearing, the mixer shaft 4 is provided with a stirring blade 5, and the stirring blade 5 in this embodiment is along the mixer shaft 4. The axes are spirally arranged on the outer peripheral wall of the sha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com