Device and process for recovering volatile organic gas

A volatile organic and recovery device technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of air environmental quality degradation, waste of resources, and potential safety hazards, and reduce the accumulation of heavy hydrocarbons , Improving device efficiency and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

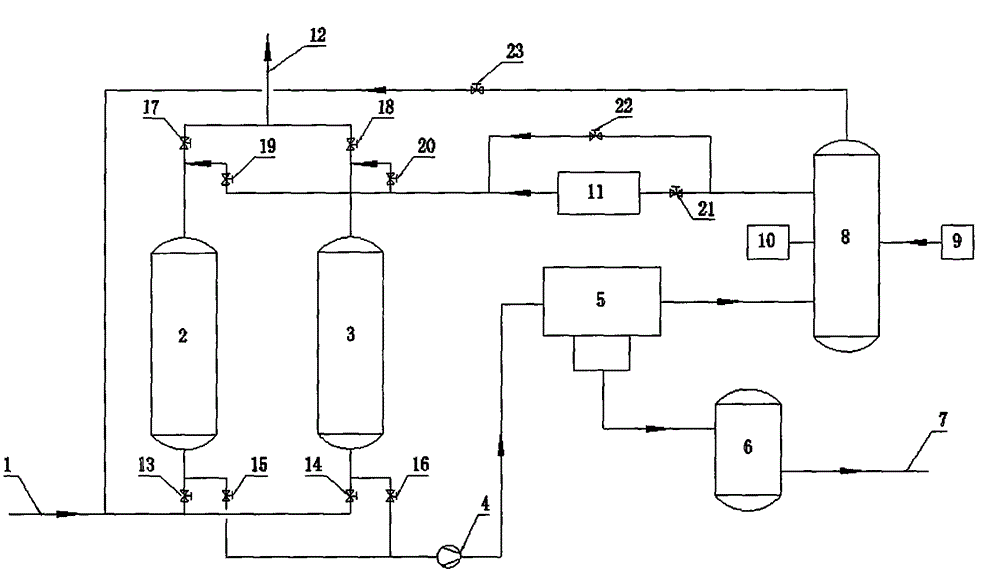

[0030] figure 1 It is a schematic diagram of the volatile organic gas recovery device of the present invention. The device of the present invention includes an adsorption tower A2, an adsorption tower B3, a vacuum pump 4, a condensing unit 5, a recovery tank 6, a recycling gas tank 8, a nitrogen automatic pressure stabilizing device 9, an oxygen content analyzer 10, and a heat exchanger 11. Wherein, the volatile organic gas inlet pipe 1 is connected to the bottom of the adsorption tower A 2 and the adsorption tower B 3 respectively through two branch pipelines, and the inlet valves 13 and 14 are respectively installed on the two branch pipelines; the adsorption tower A 2 and the top of adsorption tower B 3 are respectively provided with exhaust valves 17, 18; one end of vacuum pump 4 is connected to the bottom of adsorption tower A 2 and adsorption tower B 3 respectively through two branch pipelines, and the two branch pipelines are equipped with evacuation valves respectively...

Embodiment 2

[0033] The device described in Example 1 is used to recover the oily waste gas produced during the gasoline transfer process, and activated carbon is used as the adsorbent. The specific process is as follows: the oily waste gas first enters the adsorption tower A2 through the intake pipe 1, wherein the gaseous oily waste gas is absorbed. The adsorbent in the tower is adsorbed and intercepted, and the clean tail gas is discharged into the atmosphere through the purified gas exhaust pipe 12; when the adsorption of the adsorption tower A 2 is close to saturation, it switches to the desorption regeneration program; and the intake valve 14 and exhaust valve of the adsorption tower B 3 are opened 18. Close the evacuation valve 16 and the flushing valve 20 of the adsorption tower B3, so that the adsorption tower B3 enters the adsorption procedure; after the desorption regeneration procedure of the adsorption tower A2 ends, the adsorption procedure is switched on, and the adsorption tow...

Embodiment 3

[0042] Adopt the device described in embodiment 1 to reclaim dimethyl carbonate volatile gas, adopt active carbon+molecular sieve to be adsorbent, concrete technological process is: first oil gas enters adsorption tower A 2 by inlet pipe 1, wherein gaseous dimethyl carbonate Absorbed and intercepted by the adsorbent in the tower, the clean tail gas is discharged into the atmosphere through the purified gas exhaust pipe 12; when the adsorption of the adsorption tower A 2 is close to saturation, it switches to the desorption regeneration program; and the intake valve 14 and the exhaust gas of the adsorption tower B 3 are opened. Valve 18 closes the evacuation valve 16 and flushing valve 20 of adsorption tower B, so that adsorption tower B 3 enters the adsorption program; after the desorption regeneration program of adsorption tower A 2 ends, it cuts into the adsorption program, and adsorption tower B 3 enters the desorption regeneration program. Switching in turns, wherein, the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com