Multi-impellor rotary vane type hydrodynamic cavitation generator and hydrodynamic cavitation method

A hydraulic cavitation and generating device technology, which is applied in the direction of mechanical oscillation water/sewage treatment, components of pumping devices for elastic fluids, non-variable pumps, etc., can solve the problem that is not enough to trigger physical and chemical reactions or Intensify the effect, deal with problems such as the large pipeline structure of the system, and the small hydraulic cavitation intensity, so as to achieve the effect of low equipment manufacturing cost, reduced scale and complexity, and reduced floor space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

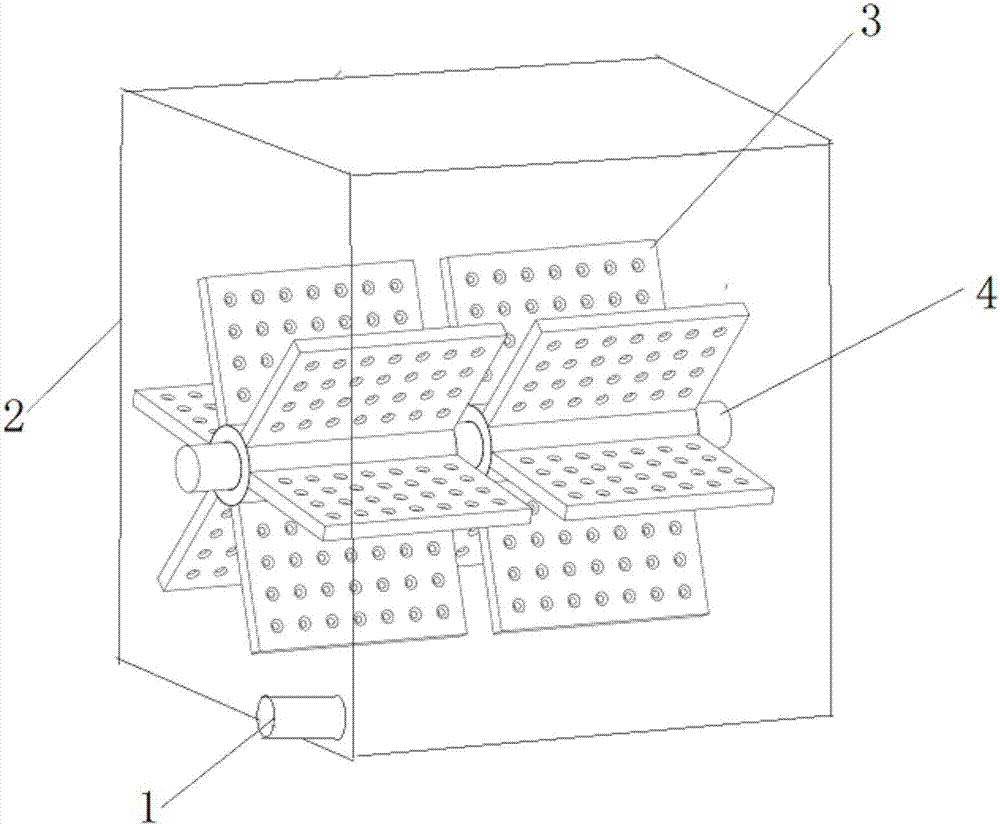

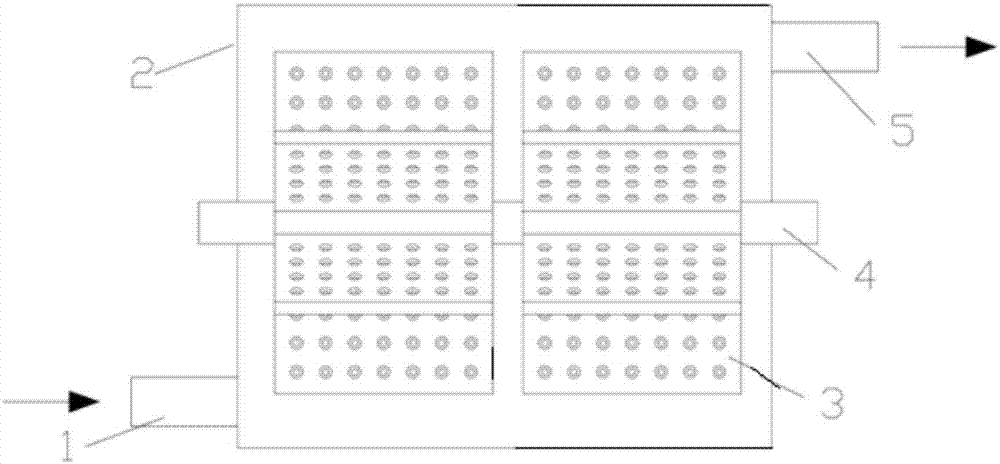

[0043] A multi-impeller rotary blade type hydraulic cavitation generating device, comprising:

[0044] The box body 2 is used to accommodate the liquid. The bottom end of the front side is provided with a liquid inlet 1, and the top end of the rear side is provided with a liquid outlet 5. The liquid inlet 1 and the liquid outlet 5 are respectively arranged at both ends of the diagonal line of the box body;

[0045] Cavitation bodies, including,

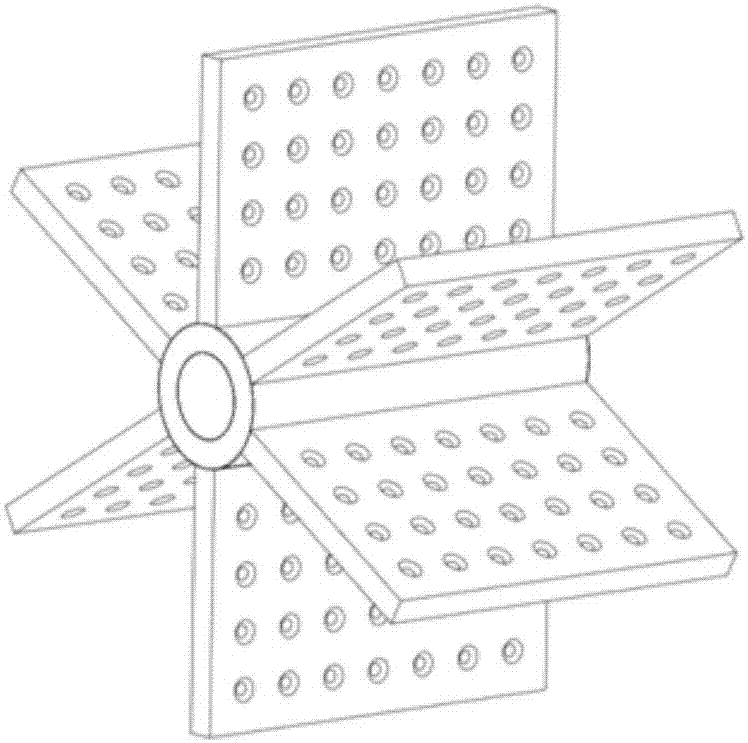

[0046] The rotating shaft 4 is installed in the center of the box body 2 and driven by an external motor;

[0047] A plurality of impellers 3 are all coaxially installed on the rotating shaft 4, and each is composed of a plurality of blades...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com