Solid wood door leaf and manufacturing method thereof

A manufacturing method and technology of solid wood doors, applied to door leaves, windows/doors, manufacturing tools, etc., can solve problems such as easy loosening, whitening, cracked paint surface, etc., and achieve the effect of tight bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

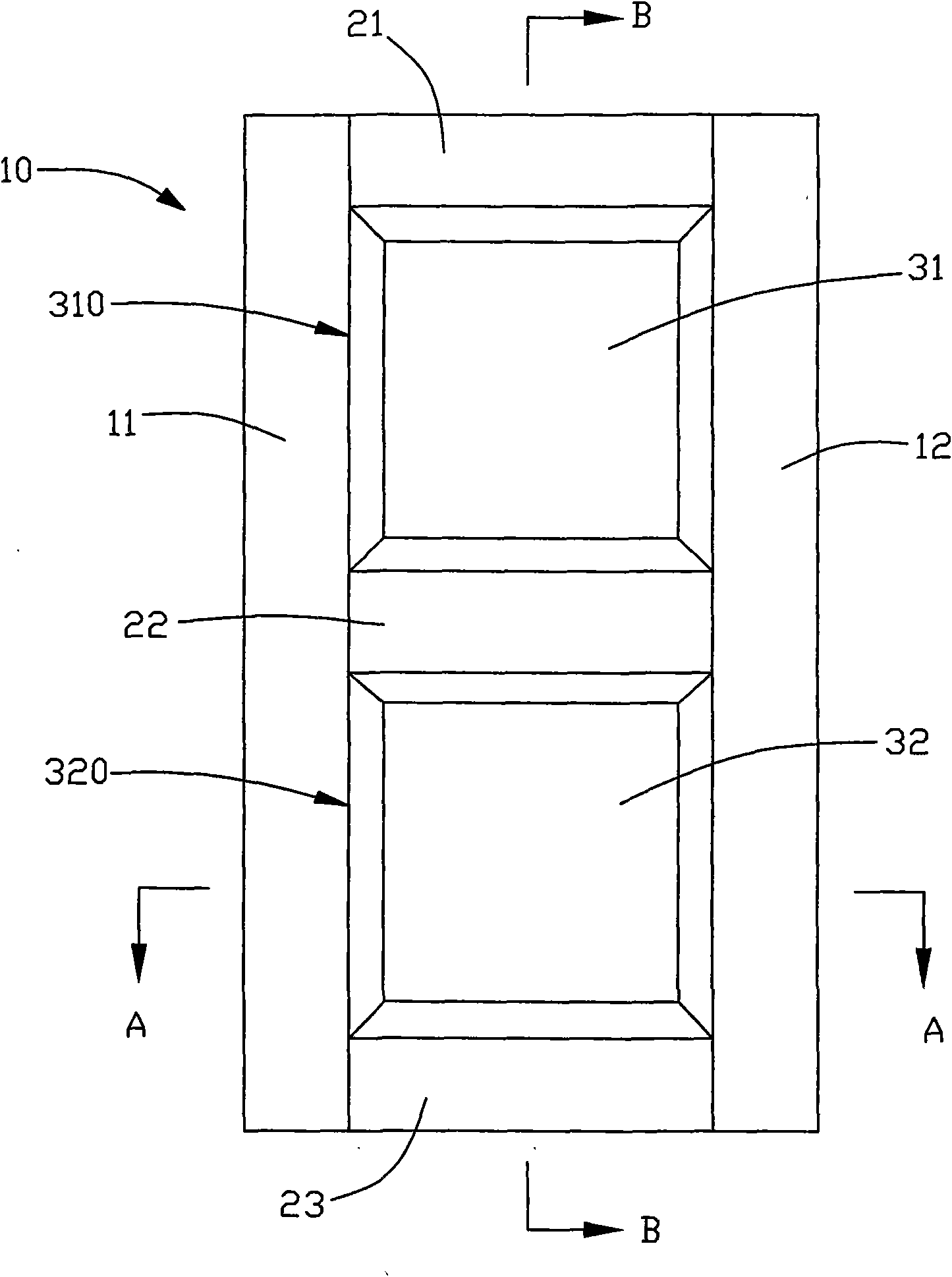

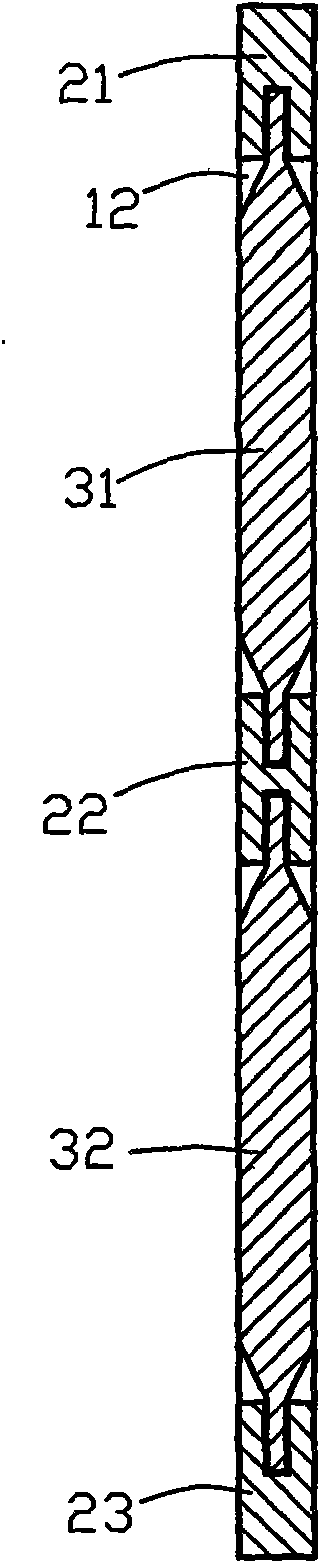

[0024] A kind of solid wood door leaf, refer to figure 1 , comprising a door leaf frame 10 and at least door blocking plates 31, 32 embedded in the door leaf frame 10, the door leaf frame 10 consists of two left and right arranged door posts 11, 12 and three vertically arranged crosspieces 21, 22 , 23 assembled, the crosspieces 21, 22, 23 are respectively connected between the upper, middle and lower parts of the door stand 11, 12, and form two door blocking plate assembly ports 310, 320, the door blocking plate 31, 32 are respectively embedded in the assembly openings 310, 320 of the door blocking plate.

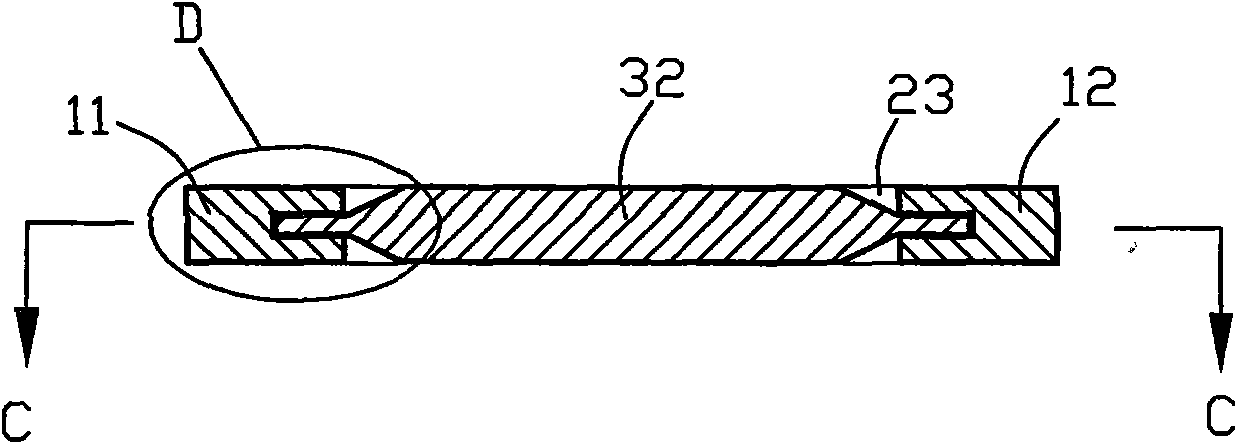

[0025] Also refer to Figure 2 to Figure 6 , the periphery of each door blocking plate assembly opening 310, 320 forms an assembly groove 100 that is embedded and assembled with the edge of the corresponding door blocking plate 11, 12. The outside of the boards 31, 32 are covered with a paint layer 112 respectively, and there are unpainted adhesive places at the bottom of...

Embodiment 2

[0030] This embodiment is basically the same as the above-mentioned embodiment one, with reference to Figure 7 with Figure 8 , the main difference is that in this embodiment, only the local positions of the bottom of the assembly groove 100 and the periphery 101 of the door blocking plates 31, 32 are used as unpainted glued places, and adhesive 111 is coated on the glued places.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com