Self-adhesive flaky material

A technology of laminated materials and self-adhesive layers, applied in the direction of adhesives, film/sheet adhesives, special decorative structures, etc., can solve the problems of laminate application and smooth processing, and achieve high peeling resistance and energy saving Effect of raw material, high static shear strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

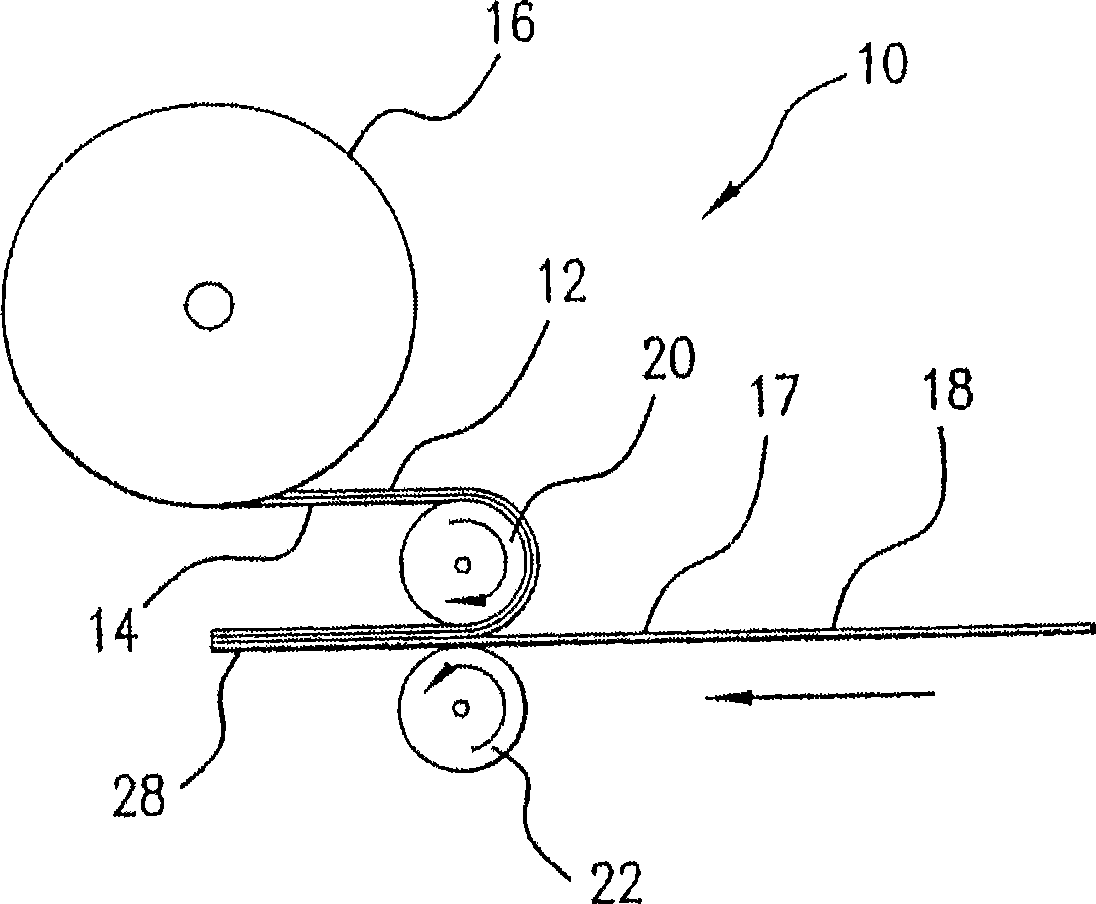

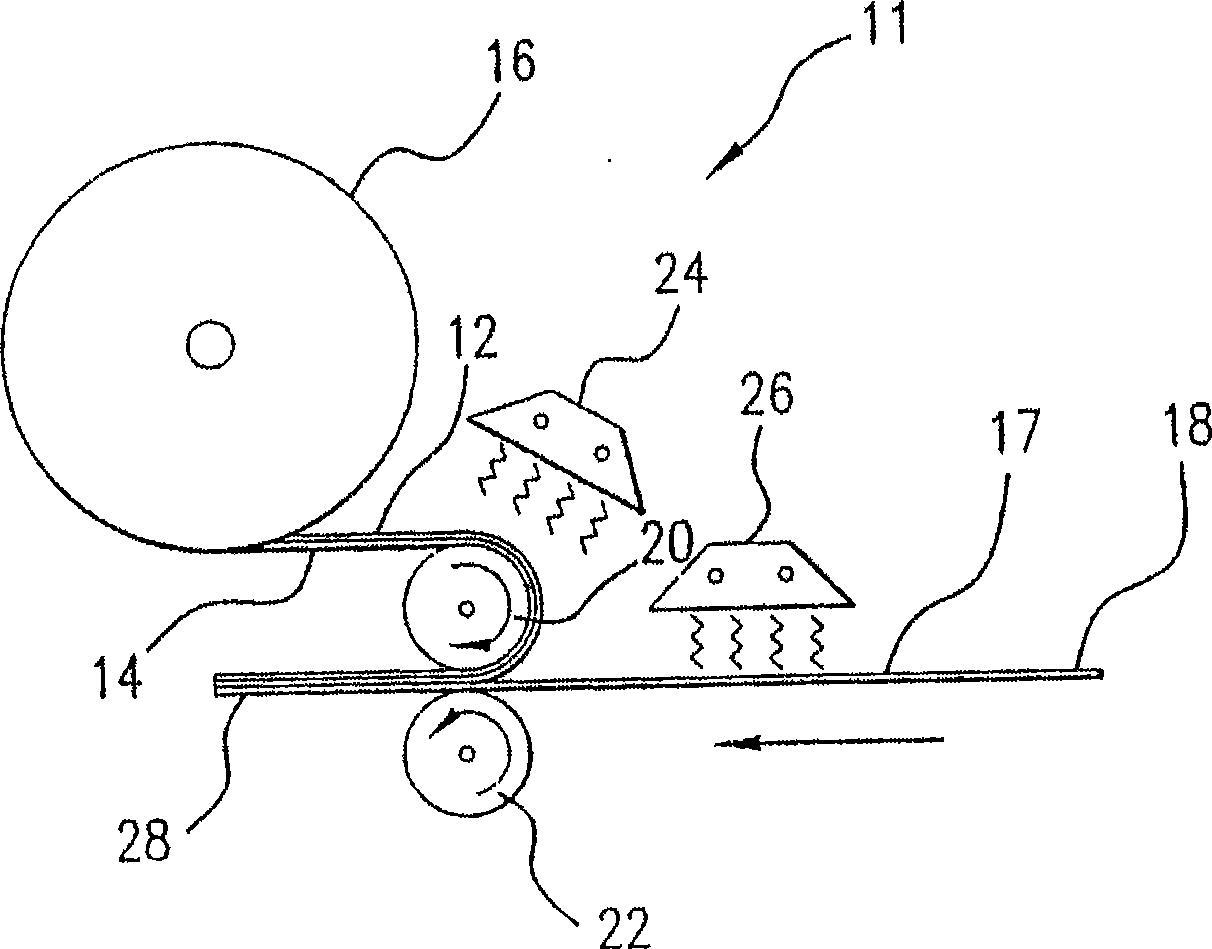

[0030] The present invention provides a decorative laminate substrate having a self-adhesive layer applied directly or indirectly to one side of the laminate substrate. In one embodiment of the present invention, the self-adhesive layer comprises a physically coated, solvent-free, acrylic polymer-containing adhesive material at room temperature. When bonded to a carrier, the adhesive-coated laminate substrate of the present invention provides improved bond strength or adhesion, heat and moisture resistance, and adequate shear strength or creep resistance. Adhesive-coated laminate substrates can be applied relatively easily by the end user compared to typically known adhesive systems.

[0031]According to the present invention, "laminate substrates" include materials such as, for example, fiberglass fabrics, paper, wood, textiles, plastic films, paper-based laminates, laminate fabrics, laminates, which have been impregnated or coated with, for example, epoxy Paper or fabric ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com