Detachment device and detachment method

A peeling device and spacer technology, which is applied in transportation and packaging, sending objects, lamination, etc., can solve the problems of unguaranteed peeling reliability, low peeling efficiency, uneconomical, etc., and achieve the effect of preventing bad peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

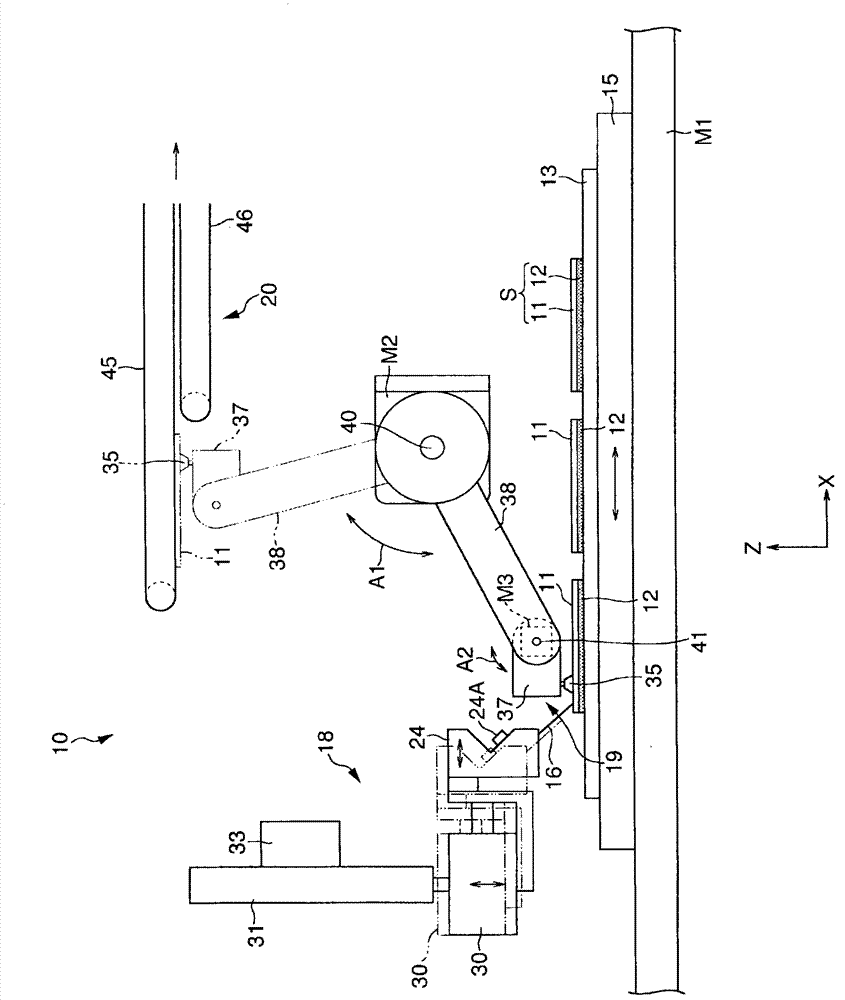

[0059] Next, preferred embodiments of the present invention will be described with reference to the drawings.

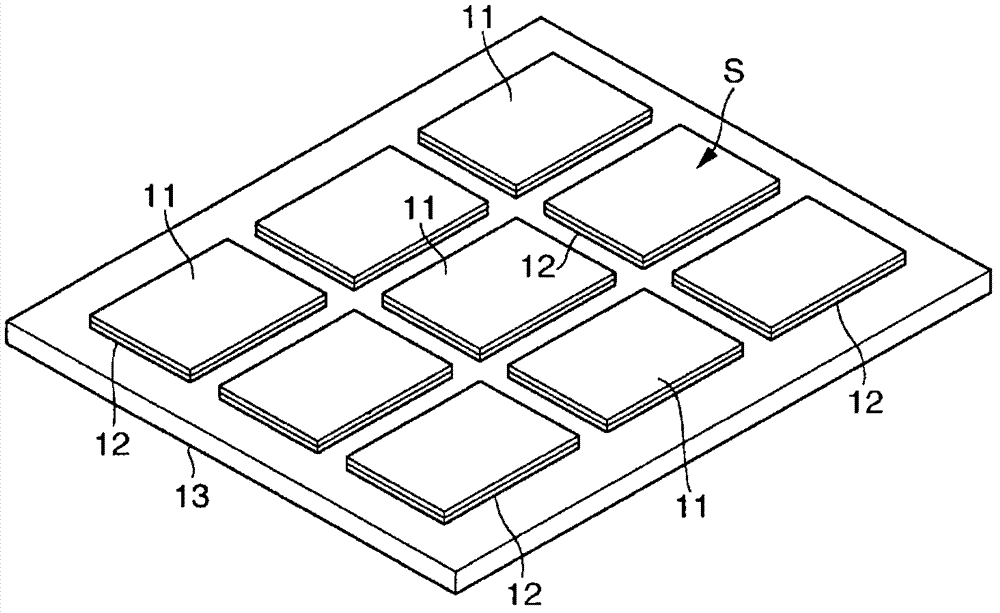

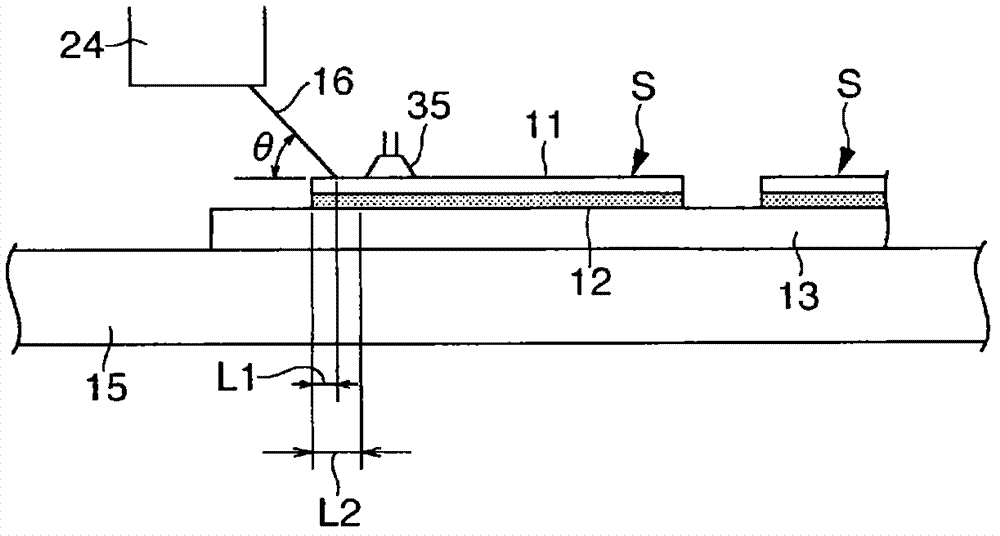

[0060] exist figure 1Among them, the sticking device 10 is configured as a device that sticks the adhesive sheet S having an adhesive layer 12 covered with a separator 11 on a substrate 13 as an adherend, The separator sheet 11 is peeled off from the adhesive layer 12 . The separator 11 is substantially the same as what is generally called a release sheet, and examples of the material include polyethylene terephthalate and the like. The separator is formed of a film having a thickness of 10 μm to 60 μm, particularly preferably about 50 μm, after the surface on the side of the adhesive layer 12 is peeled. In addition, the adhesive layer 12 is not particularly limited, but is preferably composed of a reactive hot-melt adhesive, and its layer thickness is 10 μm to 40 μm, particularly preferably about 20 μm. In this embodiment, if figure 2 As shown, the adhesive sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com