Photocurable pressure-sensitive adhesive composition, photocurable pressure-sensitive adhesive layer, and photocurable pressure-sensitive adhesive sheet

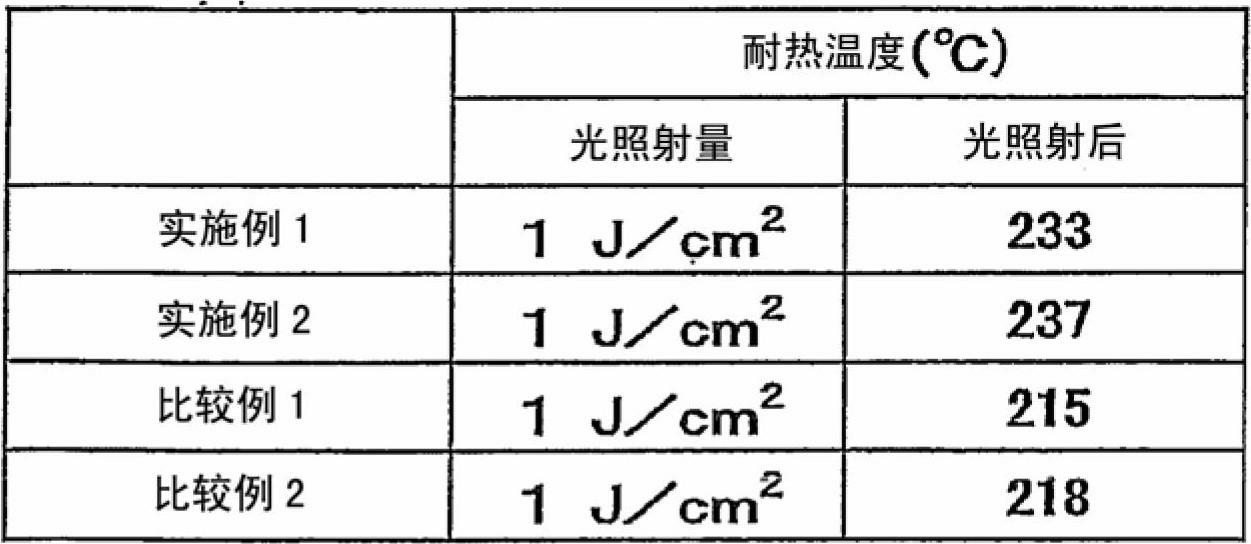

An adhesive layer, light-curing technology, applied in the direction of adhesive types, non-polymer adhesive additives, adhesive additives, etc., can solve the problem of difficulty in preventing glue leakage, and achieve the maintenance of fluidity and adhesion. Excellent effect with excellent heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

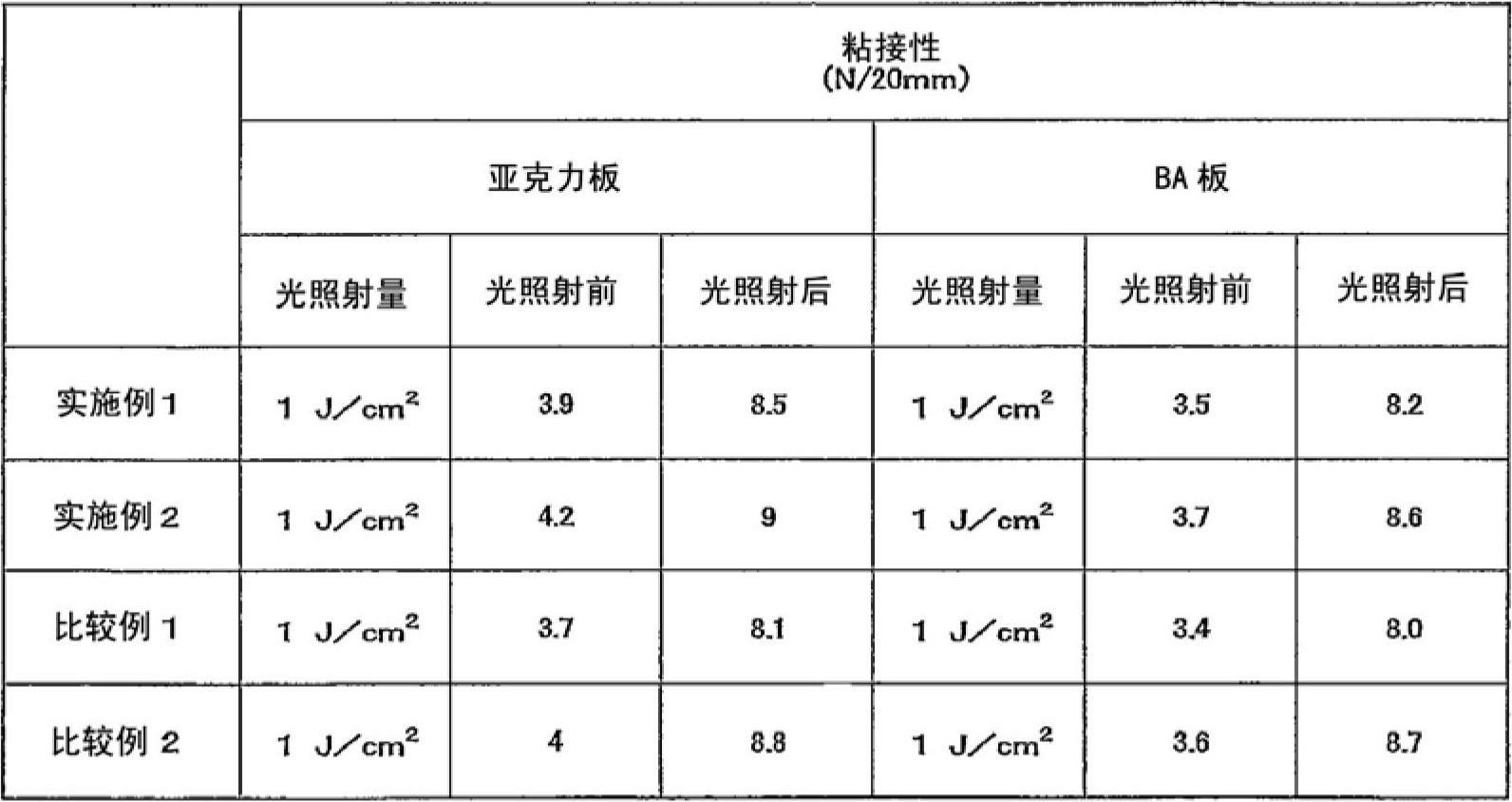

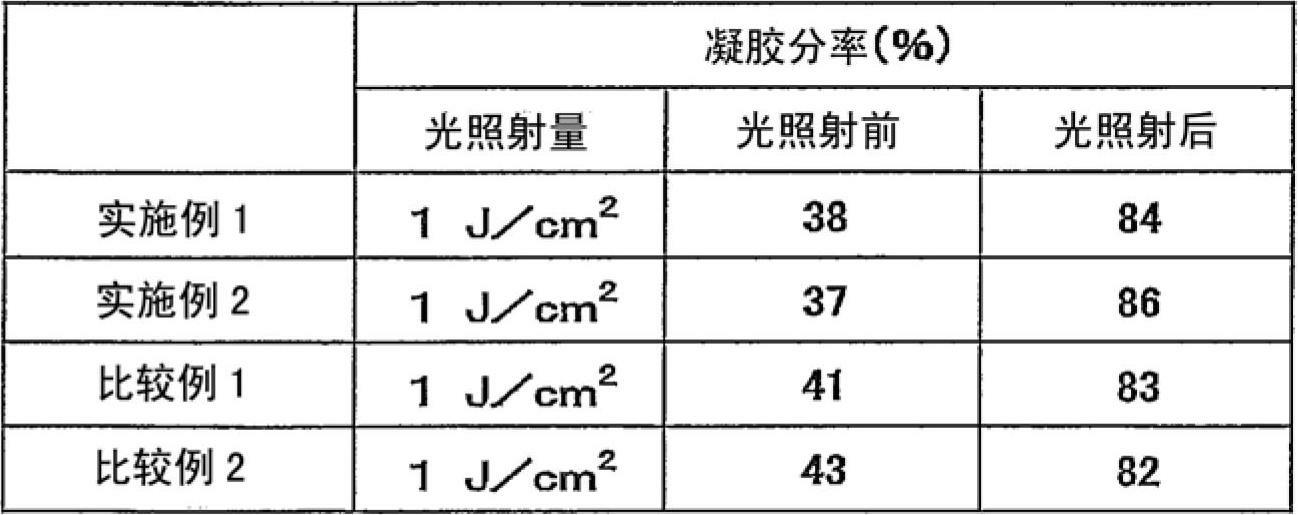

Examples

Embodiment 1

[0134] (Preparation of Acrylic Polymer)

[0135] 97 parts by weight of n-butyl acrylate, 3 parts by weight of hydroxyethylacrylamide (KONJIN HEAA), and 0.1 parts by weight of 2 , 2'-Azobisisobutyronitrile was put in together with 140 parts by weight of ethyl acetate and 60 parts by weight of toluene, nitrogen gas was introduced while stirring slowly, nitrogen replacement was carried out for 1 hour, and then the liquid temperature in the flask was kept at 55°C The polymerization reaction was carried out for 10 hours to prepare an acrylic polymer solution with a weight average molecular weight of 900,000. The glass transition temperature of the obtained acrylic polymer was 225K.

[0136] (Preparation of graft polymer)

[0137] The obtained acrylic polymer solution was diluted with ethyl acetate so that the solid content was 25%, to prepare a diluted solution (I). In a four-neck flask equipped with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, 10 parts...

Embodiment 2

[0148] (Preparation of Acrylic Polymer)

[0149] An acrylic polymer solution was prepared in the same manner as in Example 1.

[0150] (Preparation of graft polymer)

[0151] The obtained acrylic polymer solution was diluted with ethyl acetate so that the solid content was 25%, to prepare a diluted solution (I). In a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, 10 parts of 4-hydroxybutyl glycidyl acrylate, 10 parts of isobornyl acrylate and 400 parts by weight of the diluted solution (I) were added. 0.1 part of benzoyl peroxide, introduce nitrogen gas while slowly stirring, carry out nitrogen replacement for 1 hour, then keep the liquid temperature in the flask at around 60°C for 4 hours, then carry out polymerization reaction at 70°C for 4 hours to obtain the following polymer solution.

[0152] (Formation of Adhesive Adhesive Layer) Adhesive force measurement sample: 2A

[0153] Next, 0.3 parts by weight of a tr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com