Photocurable adhesive composition, photocurable adhesive layer, and photocurable adhesive sheet

An adhesive layer, light-curing technology, applied in the direction of adhesive types, non-polymer adhesive additives, adhesive additives, etc., can solve problems such as difficulty in preventing glue leakage, and achieve excellent adhesion and heat resistance. Excellent performance and easy handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

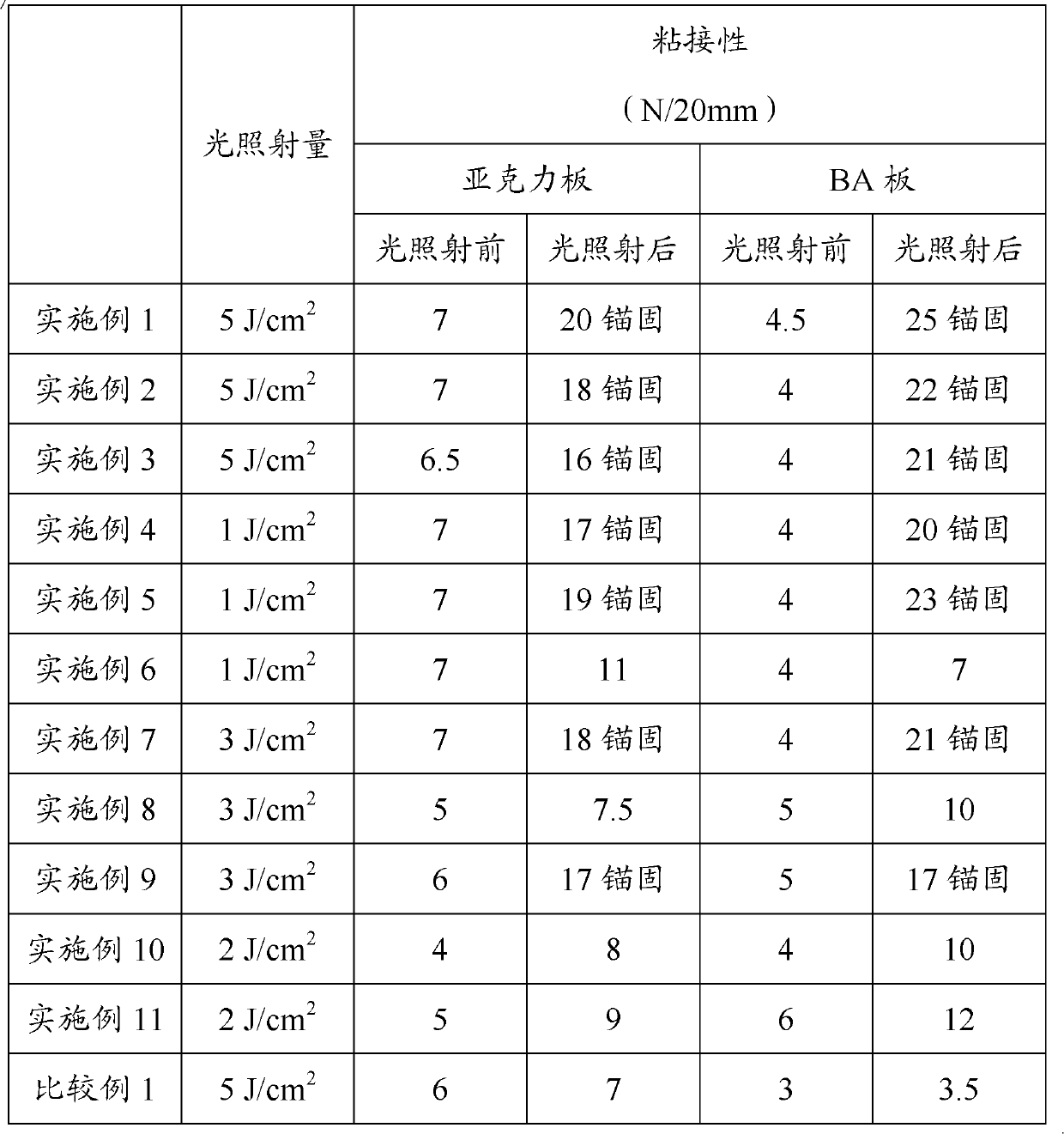

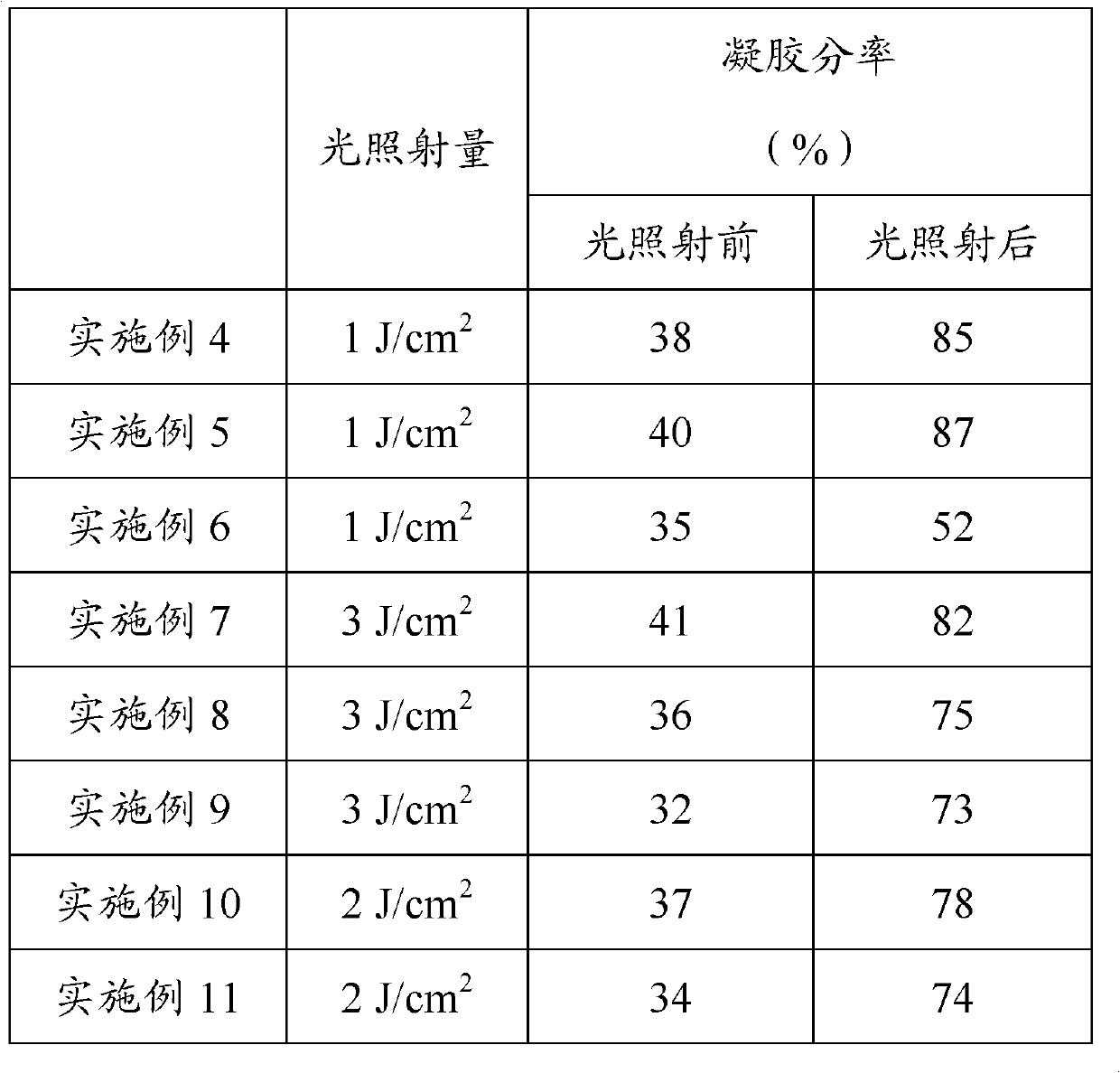

Examples

Embodiment 1

[0137] (Preparation of Acrylic Polymer)

[0138] In a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, 99 parts by weight of n-butyl acrylate, 1 part by weight of 4-hydroxybutyl acrylate, and 0.1 part by weight of 2,2' as a polymerization initiator - Azobisisobutyronitrile was charged together with 200 parts by weight of ethyl acetate, nitrogen replacement was carried out for 1 hour while slowly stirring, and then the liquid temperature in the flask was kept at around 55°C to carry out polymerization reaction for 10 hours , to prepare an acrylic polymer solution with a weight average molecular weight of 1.8 million. The glass transition temperature of the obtained acrylic polymer was 225K.

[0139] (Preparation of graft polymer)

[0140] The obtained acrylic polymer solution was diluted with ethyl acetate so that the solid content would be 25%, to prepare a diluted solution (I). In a four-necked flask equipped with sti...

Embodiment 2

[0147] (Preparation of Acrylic Polymer)

[0148] In a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, 99 parts by weight of n-butyl acrylate, 1 part by weight of 4-hydroxybutyl acrylate, and 0.1 part by weight of 2,2' as a polymerization initiator - Azobisisobutyronitrile was charged together with 200 parts by weight of ethyl acetate, nitrogen replacement was carried out for 1 hour while slowly stirring, and then the liquid temperature in the flask was kept at around 55°C to carry out polymerization reaction for 10 hours , to prepare an acrylic polymer solution with a weight average molecular weight of 1.8 million. The glass transition temperature of the obtained acrylic polymer was 225K.

[0149] (Preparation of graft polymer)

[0150] The obtained acrylic polymer solution was diluted with ethyl acetate so that the solid content would be 25%, to prepare a diluted solution (I). In a four-necked flask equipped with sti...

Embodiment 3

[0157] (Preparation of Acrylic Polymer)

[0158] In a four-necked flask equipped with a stirring blade, a thermometer, a nitrogen inlet tube, and a condenser, 99 parts by weight of n-butyl acrylate, 1 part by weight of 4-hydroxybutyl acrylate, and 0.1 part by weight of 2,2' as a polymerization initiator - Azobisisobutyronitrile was charged together with 200 parts by weight of ethyl acetate, nitrogen replacement was carried out for 1 hour while slowly stirring, and then the liquid temperature in the flask was kept at around 55°C to carry out polymerization reaction for 10 hours , to prepare an acrylic polymer solution with a weight average molecular weight of 1.8 million. The glass transition temperature of the obtained acrylic polymer was 225K.

[0159] (Preparation of graft polymer)

[0160] The obtained acrylic polymer solution was diluted with ethyl acetate so that the solid content would be 25%, to prepare a diluted solution (I). In a four-neck flask equipped with stirr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com