Petrolatum containing hot melt bottle labeling adhesive

A technology of hot melt adhesive and petrolatum, applied in the direction of wax adhesive, rosin adhesive, adhesive, etc., can solve the problems of adhesive creep, labeling failure, etc., and achieve the effect of increasing creep resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

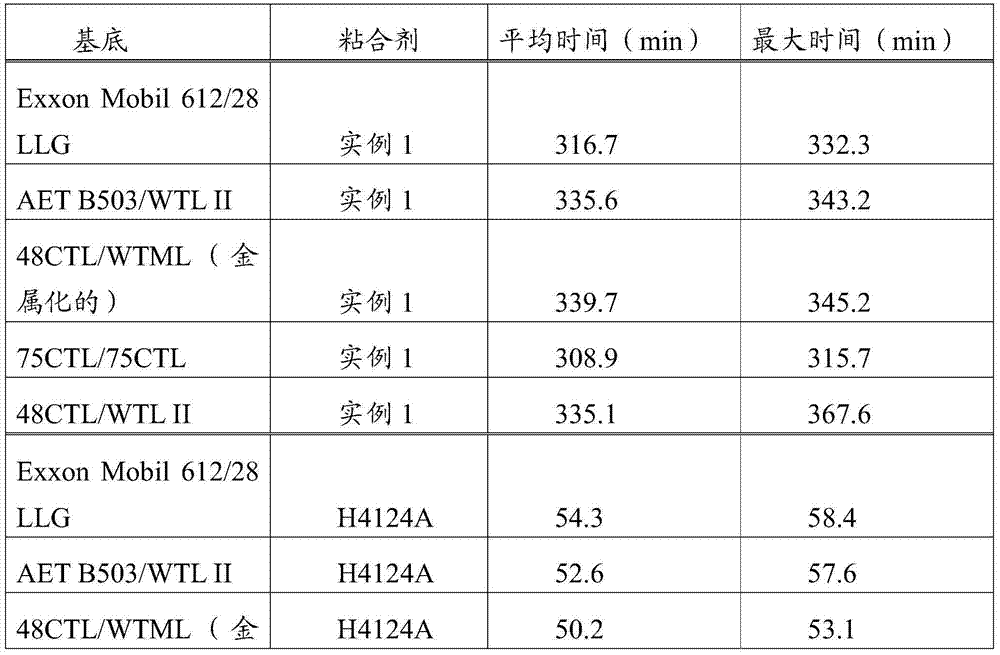

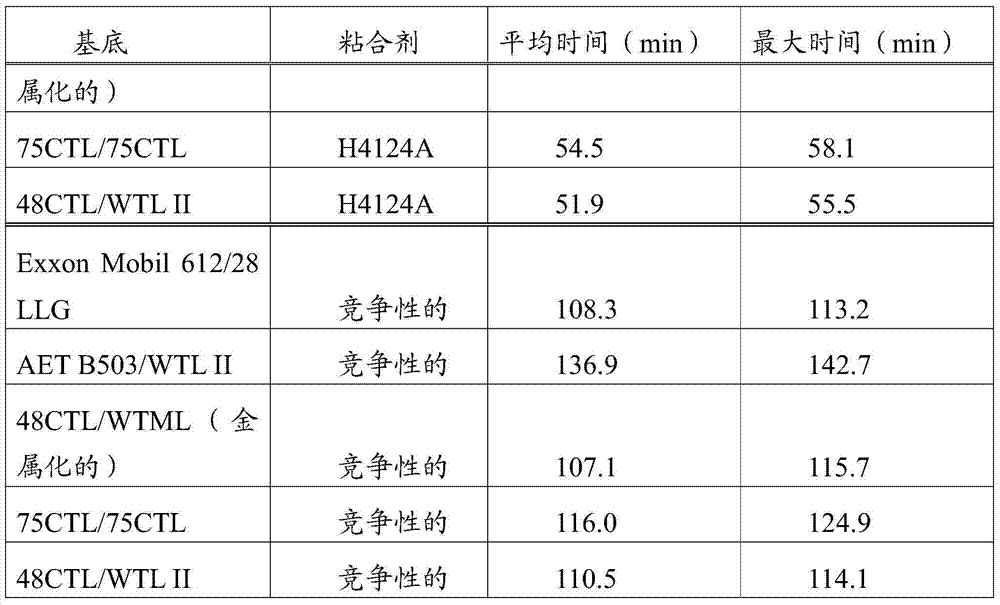

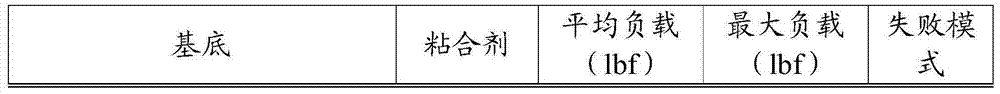

[0013] It has been found that the use of petrolatum in hot melt adhesive bottle labeling formulations increases creep resistance without sacrificing adhesion to plastic film substrates. In addition, petrolatum-containing adhesives do not exhibit oil migration into sensitive film stocks, thereby reducing aesthetically undesirable wrinkling.

[0014] The present invention consists of styrene block copolymer (SBC), petrolatum, polyolefin, tackifying resin and optionally waxes, plasticizers, stabilizers or other auxiliary additives. Although the examples illustrate hot melt adhesives composed of SBC and EVA polymers, it has been found that other polyolefin polymers can be used in place of EVA, including but not limited to propylene / ethylene copolymers , ethylene / α-olefin copolymers, olefin block copolymers, ethylene n-butyl acrylate copolymers, metallocene-catalyzed polyethylene and others.

[0015] Historically, liquid plasticizers, usually mineral oil, have been used in pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com