Hot melt adhesive

A hot-melt adhesive and weight technology, applied in the direction of adhesives, wax adhesives, etc., can solve the problems of exceeding the standard and non-compliance, and achieve the effect of saving process energy consumption, high bonding strength, and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] Embodiment 1 main bonding agent is ethylene-vinyl acetate copolymer

[0073] A hot melt adhesive, see Table 1 for specific components and contents.

[0074] EVA1~EVA6 in Table 1 are different kinds of ethylene-vinyl acetate copolymers, wherein the proportion of vinyl acetate to the weight of ethylene-vinyl acetate copolymers is represented by VA%, and the individual melt index (Melting Index, MI; MI value The higher the value, the better the liquidity).

[0075] Then the strength is tested by the Chinese QB / T2358-98 test method.

[0076] The evaporation residue of n-hexane is tested according to the Chinese GB / T5009.60-2003 test method.

[0077] Table 1 Hot melt adhesives of different formulations and their properties

[0078]

[0079]

[0080] It can be seen from Table 1: in the 1-1 and 1-2 formulas, the content of the diluent polypropylene wax is relatively high, no tackifying resin is added, and the 1-1 formula with a low content of ethylene-vinyl acetate co...

Embodiment 2

[0082] Embodiment 2 main binding agent is ethylene-methacrylate copolymer

[0083] A hot melt adhesive, see Table 2 for specific components and contents.

[0084] EMMA1 to EMMA4 in Table 2 are different types of ethylene-methacrylate copolymers, where the ratio of methacrylate to the weight of ethylene-methacrylate copolymers is represented by MMA%, and individual MI values are listed. Then the strength is tested by the Chinese QB / T2358-98 test method. The evaporation residue of n-heptane is tested according to the method specified in Article 6 of Taiwan's Food Utensil Container Packaging Hygienic Standard. The n-hexane extract and xylene solubles are tested in accordance with the relevant regulations of US 21CFR, 177.1520.

[0085] Table 2 Hot melt adhesives of different formulations and their properties

[0086]

[0087]

[0088] It can be seen from Table 2 that the adhesion strength of 2-1~2-3, 2-6 and 2-8 without adding tackifying resin is 2.12-9.12N / 10mm, among...

Embodiment 3

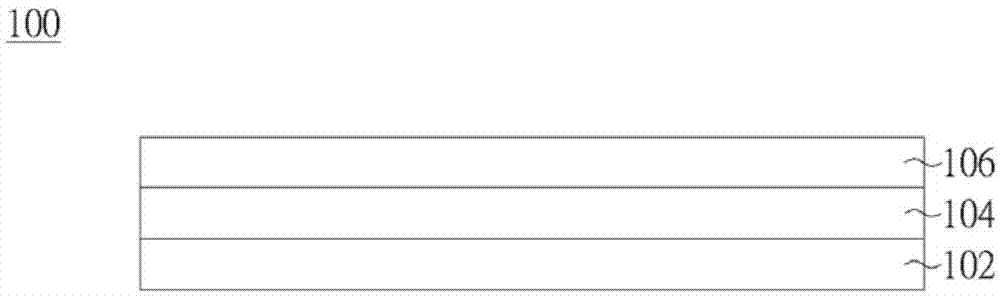

[0090] Application of embodiment 3 hot melt adhesive in sealing material

[0091] 1. The structure of the sealing material

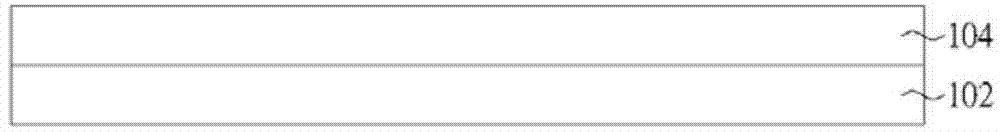

[0092] refer to figure 1 , which is the sealing material 100. The sealing material 100 includes a metal foil 102 , a coating 104 and the hot melt adhesive 106 obtained in Example 1 or 2.

[0093] Wherein, the metal foil 102 may be commonly used aluminum foil. Aluminum foil can react with oxygen in the air to form a protective layer of aluminum oxide, thereby blocking the moisture in the air.

[0094] The material of the coating film 104 can be polyethylene (PE) or polypropylene (PP). The coating film 104 can prevent chemical reaction between the food and the metal foil 102 , and can improve the adhesion of the hot melt adhesive 106 to the metal foil 102 .

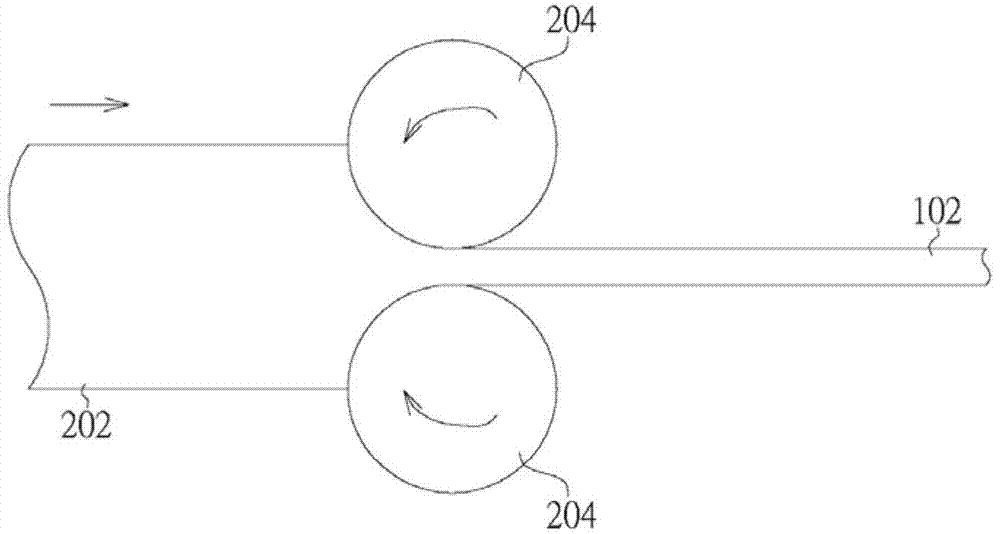

[0095] The hot melt adhesive 106 is used to provide adhesion between the sealing material 100 and the food container by hot pressing. The hot-melt adhesive 106 is coated on the coating film 104 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| liquidity index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com