Plastic-based binding agent and method for preparing powder injection molding green bodies through same

A powder injection molding and binder technology, applied in the directions of adhesives, wax binders, non-polymer binder additives, etc., can solve the problems of restricting the mass production of powder injection molding products, unsatisfactory filling, poor fluidity, etc. Achieving good processing stability, avoiding decomposition, and good flow properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

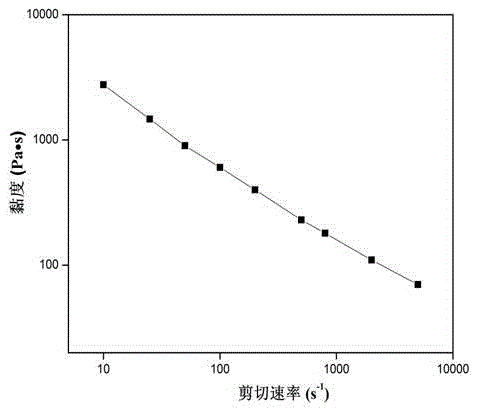

Image

Examples

Embodiment 1

[0025] The plastic-based binder in this embodiment is a plastic-based binder for powder injection molding, and consists of the following raw materials in parts by weight: polyoxymethylene 88, modified polylactic acid resin 4, microcrystalline wax 4, pentaerythritol stearate 2. Dibutyl sebacate 1.5, antioxidant 0.5. Preparation method: put all the raw materials into a high-speed mixer and mix for 30 minutes, and discharge; put the mixed raw materials into a granulator to extrude and granulate to obtain a granular binder.

[0026] The method in which the plastic-based binder of this embodiment is used to prepare the green body has the following steps:

[0027] Step 1: Feed preparation: preheat 17-4PH stainless steel metal powder with a particle size of D50≤10μm to 190°C, stir at a speed of 5r / min; add the said Binder, banburying at 190°C, mixing time is 1 hour, stirring, rotating speed is 10r / min; cooling down to 180°C, continuing banburying for 0.5 hour, stirring, rotating spe...

Embodiment 2

[0033] The plastic-based binder in this embodiment is a plastic-based binder for powder injection molding, and consists of the following raw materials in parts by weight: polyoxymethylene copolymer 82, modified polylactic acid resin 5, microcrystalline wax 5, pentaerythritol stearate 4.5, dibutyl sebacate 3, antioxidant 0.5. Put all the raw materials into a high-speed mixer and mix for 20 minutes, and discharge; put the mixed raw materials into a granulator to extrude and granulate to obtain a granular binder.

[0034] The method in which the plastic-based binder of this embodiment is used to prepare the green body has the following steps:

[0035] Step 1: Feed preparation: preheat 316L stainless steel metal powder with a particle size of D50≤10μm and D90=22 to 185°C, stir at a speed of 10r / min; add in a volume ratio of binder to metal powder of 36:64 The binder is banburyed at 185°C, the banburying time is 40 minutes, stirring, and the rotating speed is 20r / min; the temperat...

Embodiment 3

[0039] The plastic-based binder in this embodiment is a plastic-based binder for powder injection molding, and consists of the following raw materials in parts by weight: polyoxymethylene copolymer 76, modified polylactic acid resin 8, microcrystalline wax 6, pentaerythritol stearate 2. Dibutyl sebacate 7. Antioxidant 1. Put all the raw materials into a high-speed mixer and mix for 30 minutes, and discharge; put the mixed raw materials into a granulator to extrude and granulate to obtain a granular binder.

[0040] The method in which the plastic-based binder of this embodiment is used to prepare the green body has the following steps:

[0041]Step 1: Feed preparation: Preheat the ZrO2 ceramic powder with a particle size of D50≤0.85μm to 180°C, stir at a speed of 5r / min; add the binder according to the volume ratio of the binder to the metal powder at 46:54 Binder, banburying at 180°C, mixing time is 1 hour, stirring, rotating speed is 30r / min; cooling to 180°C, continuing ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com