Aldehyde collector and manufacturing method of woody panel using it

A manufacturing method and capture agent technology, applied in the direction of manufacturing tools, chemical instruments and methods, aldehyde/ketone condensation polymer adhesives, etc., can solve environmental and health hazards, limit formaldehyde release, formaldehyde cannot be fully captured, etc. problem, to achieve a high capture rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

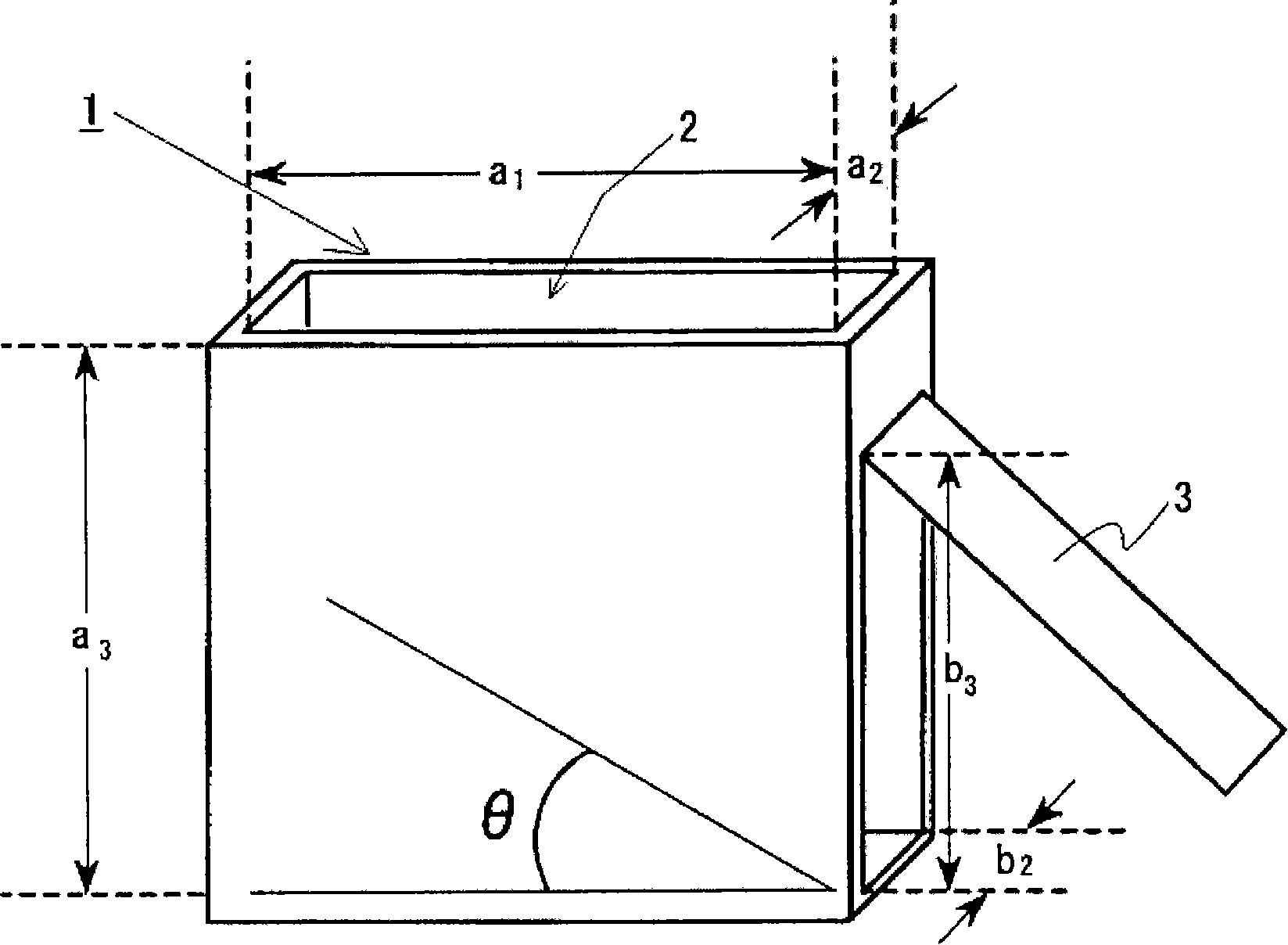

Image

Examples

Embodiment 1

[0153] The production of wooden boards

[0154] The wood chips and other wooden materials are crushed by a flaker, and sieved through a sieve with a sieve size of 1.7mm. The wooden material under the sieve is used as the wooden material for the surface and the inner layer, and the wooden material on the sieve is used as the wooden material for the core layer. The sieved wood material is dried in a hot air dryer at 90°C, and the moisture content reaches below 3%. Then use urea-formaldehyde resin (non-volatile matter 65%, urea: formaldehyde = 1:1.2mol) as a binder, in which the proportions of 20 parts, 1 part, 0.5 parts, 2 parts and 55% wax emulsion, hardened Mix ammonium chloride and water (hereinafter referred to as mixture A).

[0155] With respect to 100 parts of the wood material for the surface layer and the inner layer, spray 25 parts of the above-mentioned mixture A and mix them evenly. Then, 5 parts of sodium bisulfite powder as an aldehyde trapping agent was added, mixed, ...

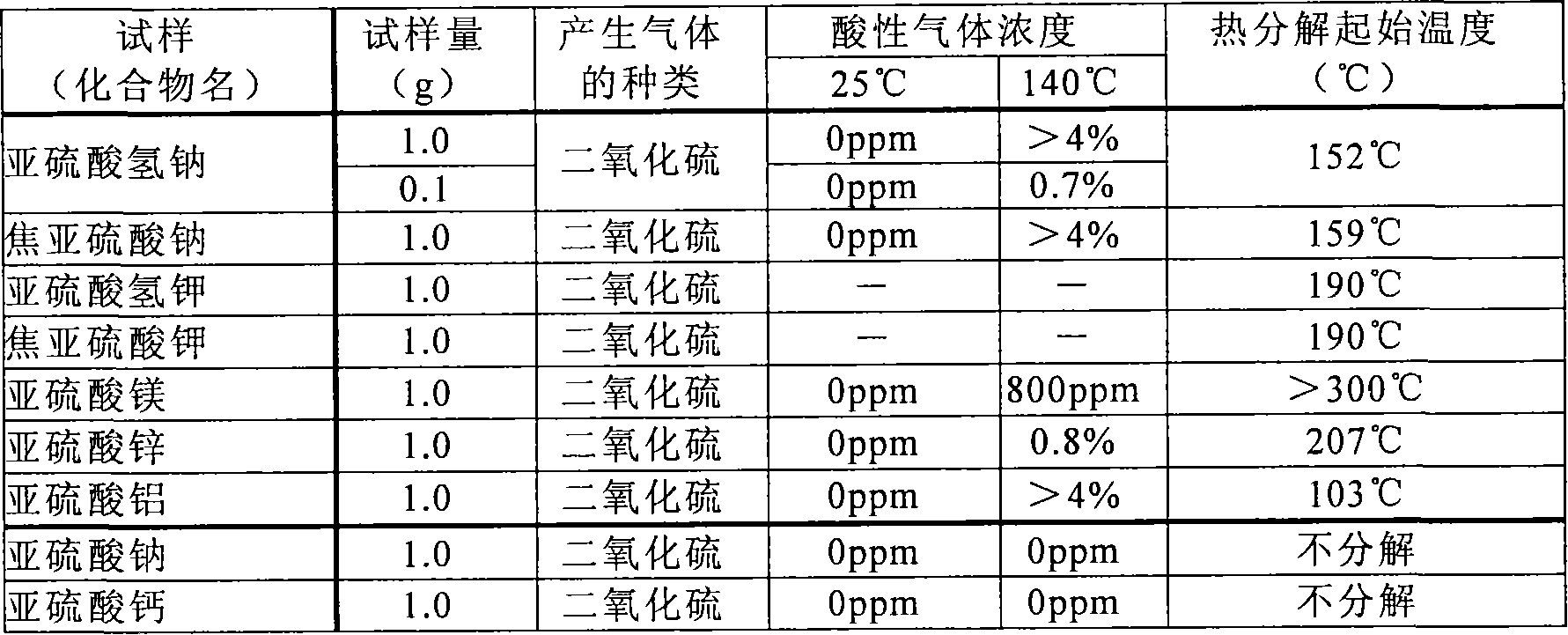

Embodiment 2~13、 comparative example 1~8

[0161] The type of the aldehyde trapping compound in Example 1 was changed to prepare an aldehyde trapping agent. The wood board was produced in the same manner as in Example 1, and the same evaluation as in Example 1 was performed. In addition, all aldehyde trapping compounds are in powder form. In addition, the addition amount of the aldehyde trapping agent was changed, and the same evaluation was performed. The results are shown in Table 4 (Examples 2 to 13) and Table 5 (Comparative Examples 1 to 8).

[0162] Table 4

[0163] Example 1

Example 2

Example 3

Example 4

Surface layer and inner layer: 5 copies

Core layer: 5 parts

Surface layer and inner layer: 5 copies

Core layer: 5 parts

Sodium metabisulfite

Surface layer and inner layer: 5 copies

Core layer: 5 parts

Potassium metabisulfite

Surface layer and inner layer: 5 copie...

Embodiment 14~23

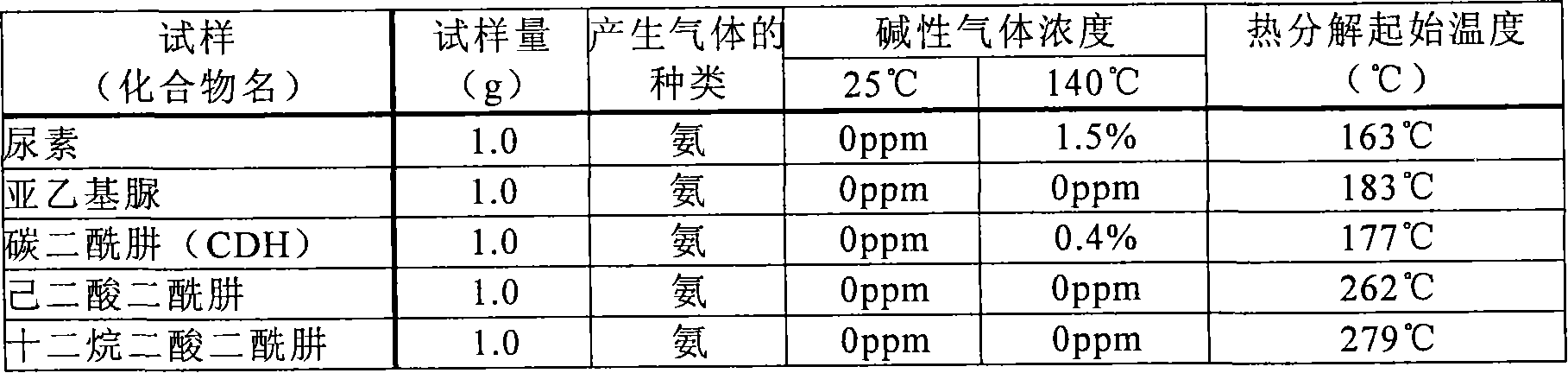

[0174] The following are the results of the aldehyde trapping agent containing two compounds: a compound that generates sulfur dioxide when heated and a compound that generates alkaline gas when heated, as shown in Table 7 (Examples 14 to 23). In addition, after uniformly mixing the used aldehyde trapping agent in advance, a wooden board was produced by the same method as in Example 1.

[0175] Table 7

[0176] Item

[0177] Item

[0178] Item

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Water absorption thickness expansion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com