Nickel aluminum bronze plastic mould material and preparation method thereof

A plastic mold, aluminum-nickel bronze technology, applied in the field of copper alloy plastic mold materials, can solve the problem of high production cost, and achieve the effects of long service life, smooth mold processing surface, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

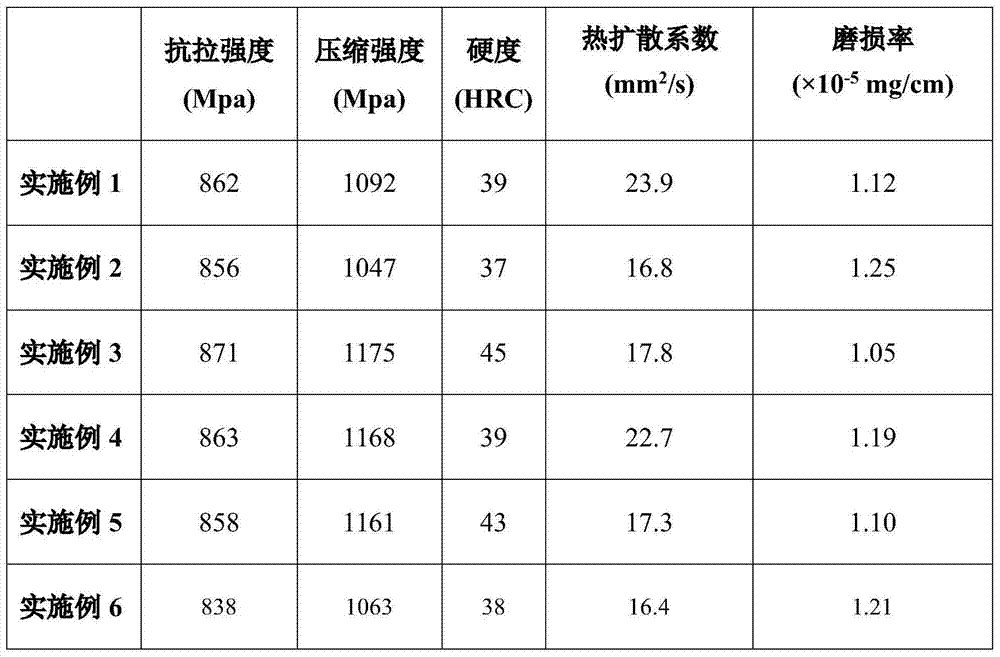

Examples

Embodiment 1

[0030] 1. Component analysis and proportioning

[0031] 1. Chemical analysis of electrolytic copper, electrolytic nickel, electrolytic manganese, electrolytic zinc, industrial pure iron, industrial pure titanium, industrial pure aluminum and industrial pure boron,

[0032] 2. Content ratio by mass percentage: Al 11%, Ni 4%, Fe 4%, Mn 1.5%, Ti 0.25%, B 0.25%, Zn 0.07%, the rest is Cu, and the total mass percentage is 100%.

[0033] 2. Preparation of Master Alloy

[0034] Electrolytic copper and industrial pure aluminum, electrolytic copper and industrial pure boron, electrolytic copper and industrial pure titanium are respectively according to mass ratio: electrolytic copper: industrial pure aluminum = 1:1, electrolytic copper: industrial pure boron = 50:1, electrolytic copper : Industrial pure titanium=25:3, smelted in a vacuum intermediate frequency induction furnace to prepare copper-aluminum master alloy, copper-boron master alloy and copper-titanium master alloy;

[0035...

Embodiment 2

[0044] 1. Weigh the charge according to the following mass percentages: Al 10%, Ni 3%, Fe 3%, Mn 1%, Ti 0.3%, B 0.3%, Zn 0.1%, the rest is Cu, and the total mass percentage is 100% .

[0045] 2. The preparation method is the same as in Example 1, and the melting temperature is strictly controlled at 1290°C, the furnace temperature at 1230°C and the pouring temperature at 1160°C.

Embodiment 3

[0047] 1. Weigh the charge according to the following mass percentages: Al 12%, Ni 5%, Fe 5%, Mn 2%, Ti 0.2%, B 0.2%, Zn 0.05%, the rest is Cu, and the total mass percentage is 100% .

[0048] 2. The preparation method is the same as in Example 1, and the melting temperature is strictly controlled at 1280°C, the furnace temperature at 1240°C and the pouring temperature at 1155°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com