Vacuum brazing process for super-Ni laminated material and Cr18-Ni8 stainless steel

A technology of cr18-ni8 and laminated materials, applied in the direction of welding/cutting media/materials, welding equipment, manufacturing tools, etc., can solve problems such as difficult to adapt to precision and complex-shaped connectors, and achieve good interface bonding and brazing seam formation Beautiful, interface combined with stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

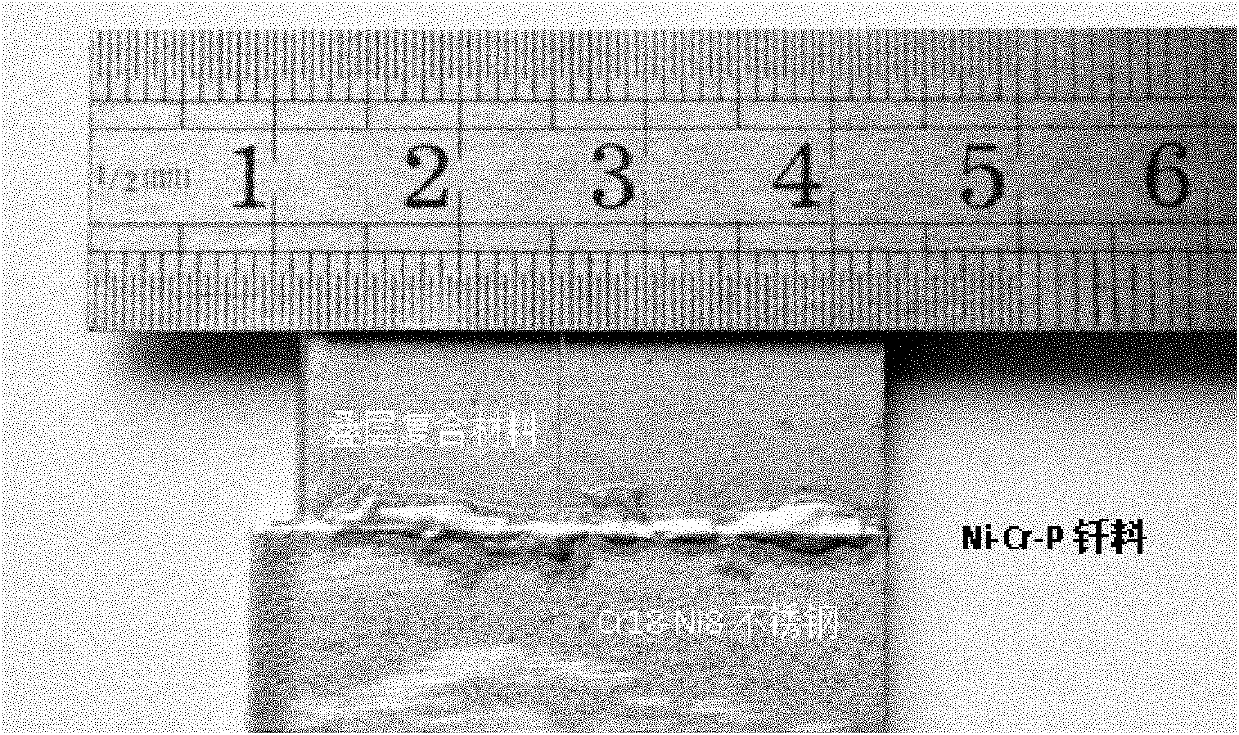

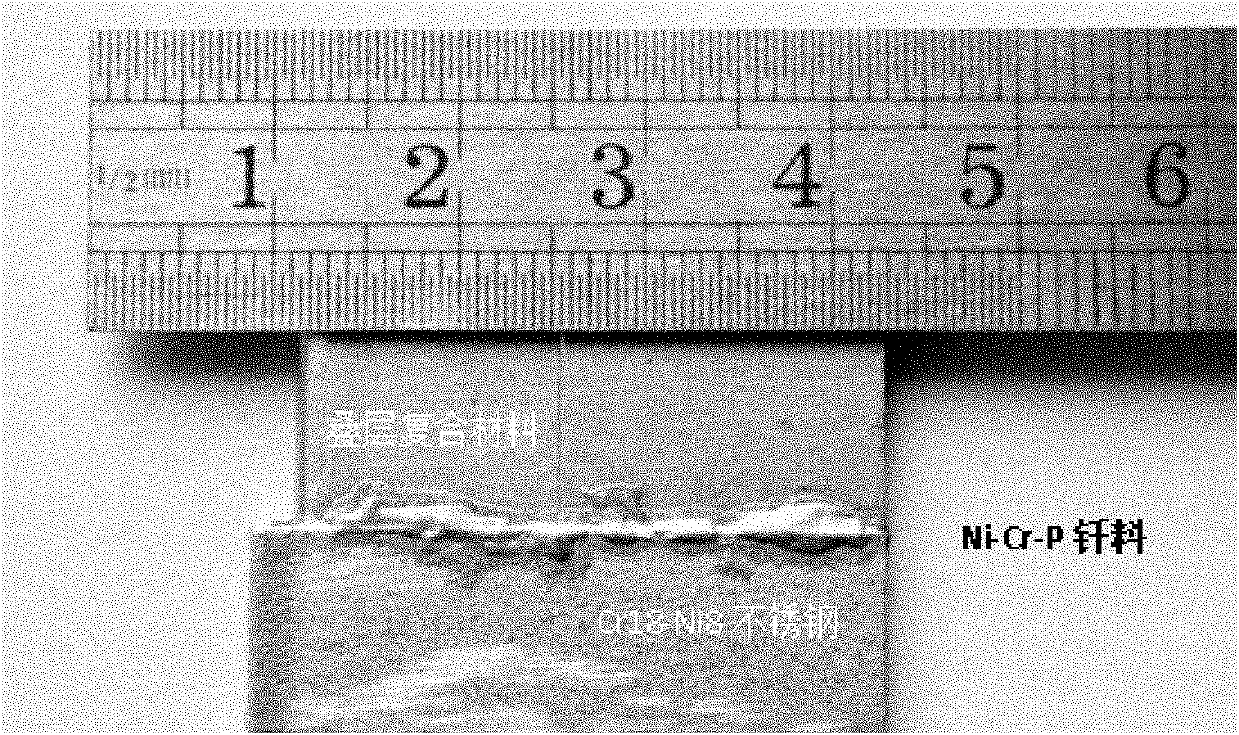

[0029] The super nickel laminated composite material with a thickness of 2.6mm is vacuum brazed with Cr18-Ni8 stainless steel with a thickness of 2.6mm. The workpiece has a length of 30mm and a width of 10mm. The thickness of the base layer of the super nickel laminated composite material is 2 mm, and the thickness of the cladding layers on both sides is 0.3 mm.

[0030] Using Ni-Cr-P solder, the main chemical composition (mass fraction) is: Ni 75.8%, Cr 14%, P 10%, C≤0.06%.

[0031] The specific vacuum brazing process steps are as follows:

[0032] Place the connected parts in an alcohol solution for ultrasonic cleaning for 3 minutes and dry them. Use No. 800 fine sandpaper to remove the oxide film on the surface of the base metal to be welded to make it as smooth as possible, rinse with alcohol and then blow dry.

[0033] In the form of butt joint, place the butt joint workpiece on the steel plate covered with graphite paper. The function of graphite paper is to prevent t...

Embodiment 2

[0037] Butt vacuum brazing of super nickel laminate composites with a thickness of 2.6 mm. The length of the connected piece is 60mm and the width is 20mm. Ni-Cr-P series solder paste is used, the chemical composition (mass fraction) is: Ni 75.8%, Cr 14%, P 10%, C≤0.06%. The heating temperature of vacuum brazing is 940℃, the holding time is 20min, and the vacuum degree is 1.33×10 -4 Pa.

[0038] The specific vacuum brazing process steps are as follows:

[0039] Place the test plate at 70-80°C with 10% Na by volume 2 CO 3Ultrasonic cleaning in the solution for 5 minutes, take out, rinse with cold water and dry. Use No. 800 fine sandpaper to remove the oxide film on the surface of the joint to make it as smooth as possible, rinse with alcohol and then blow dry.

[0040] In the form of butt joints, the connected parts are placed on the steel plate covered with graphite paper, and the Ni-Cr-P series paste solder is applied to the gap between the brazing joints. The joint gap...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com