Prepn of lanthanum nickelate-conducting metal oxide film material

An oxide film, conductive metal technology, applied in circuits, electrical components, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve the problems of impossible growth of ferroelectric thin film materials, unfavorable commercial development, and expensive raw materials , to achieve the effect of convenient operation, stable performance and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

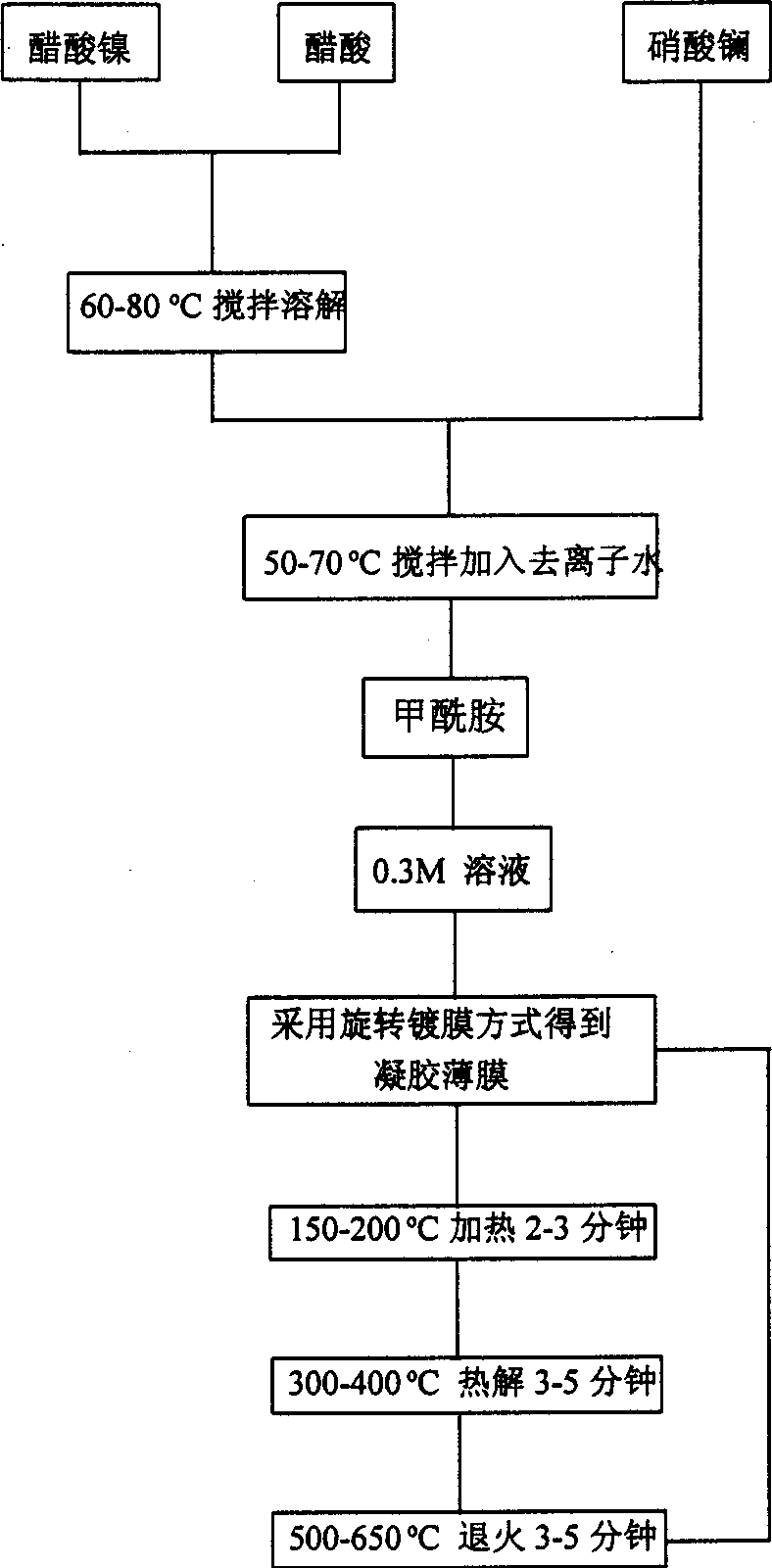

[0021] 1. LaNiO 3 Preparation of precursor solution

[0022] Weigh 0.01 mole of nickel acetate into a 100ml flask, add 50ml of acetic acid, and heat at 70°C to dissolve it. Then add the lanthanum nitrate of equimolar amount, at this moment find that dissolving is little, then slowly add 8ml deionized water under 60 ℃ and under constant stirring, until insoluble matter disappears, obtains the green transparent solution. In order to prevent cracking of the obtained lanthanum nickelate film material, 1.6ml formamide (HCONH 2 )additive. Finally, the obtained precursor solution was filtered through a 0.2 μm microporous filter, and its concentration was adjusted to 0.3 M by evaporating part of the solvent.

[0023] 2 Preparation of thin film materials

[0024] The lanthanum nickelate thin film material was prepared by the spin-coating method, and about 0.5ml of the lanthanum nickelate precursor solution was taken with a rubber dropper, and dropped on the rotating substrate at a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com