Preparation method of magnesium alloy surface micro-arc oxidation-electrophoresis composite coating

A composite coating and micro-arc oxidation technology, which is applied in metal material coating process, coating, anodic oxidation, etc., can solve the problem of low bonding strength between hydroxyapatite coating and metal surface, and achieve the purpose of suppressing arc discharge, Improve biological activity and reduce the effect of pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0021] 1. Preparation of electrolyte: Weigh raw materials of sodium aluminate or potassium aluminate 20g / l, sodium hydroxide or potassium hydroxide 3g / l, hydrogen peroxide 2ml / l, glycerol 3ml / l, sodium lactate 5ml / l , and dissolved in deionized water in turn to obtain an electrolyte for later use.

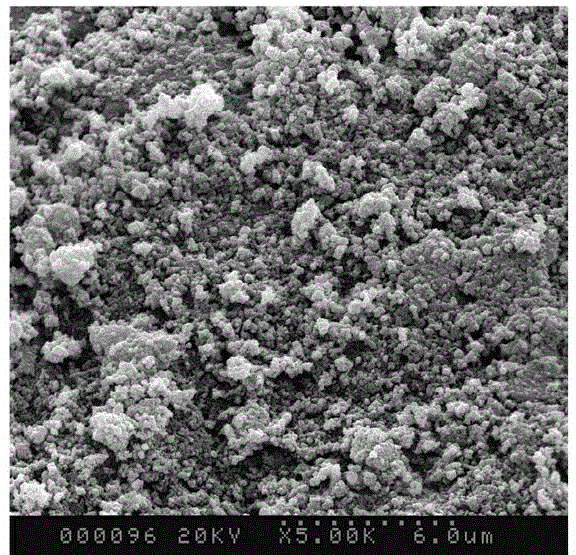

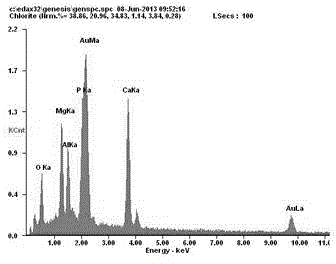

[0022] 2. Preparation of electrophoretic suspension: First, weigh 10g / l of hydroxyapatite (HA), 10ml / l of polyethylene glycol, and 2g / l of cerium nitrate, dissolve them in deionized water in turn, and adjust the pH value to 4. Then perform ultrasonic treatment for 2 hours, and finally stir for 24 hours to obtain an electrophoretic suspension for use.

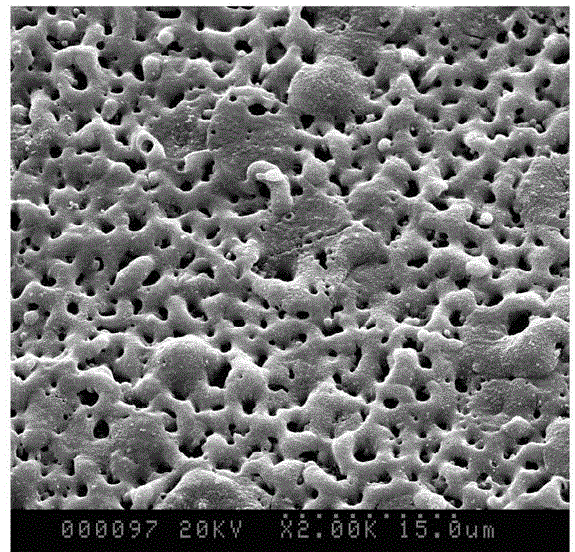

[0023] 3. Preparation of the micro-arc oxidation film on the surface of the magnesium alloy: pretreatment will be carried out (the pretreatment process means that the magnesium alloy raw material is polished and polished successively with 400, 1200, and 2000 mesh sandpaper, and then cleaned with deionized water, acetone or ethanol A...

Embodiment approach 2

[0036] The difference between this embodiment and embodiment one is that in step one, the electrolyte is composed of potassium hydroxide with a concentration of 3g / l, hydrogen peroxide at 2ml / l, glycerol at 3ml / l, sodium lactate at 8ml / l, and 20g / l l made of sodium aluminate. Other steps and process parameters are the same as the first embodiment.

Embodiment approach 3

[0038] The difference between this embodiment and the specific embodiment one is that in step one, the electrolyte is composed of potassium hydroxide with a concentration of 3g / l, hydrogen peroxide of 2ml / l, glycerol of 2ml / l, sodium lactate of 4.5ml / l and 25g / l sodium aluminate. Other steps and process parameters are the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com