Lanthanum doped nano barium ferrite film and method of manufacturing the same

A barium ferrite and lanthanum doping technology is applied in the field of preparing precursors of lanthanum-doped nano-barium ferrite, and achieves the effects of easy quantitative doping, control of film composition and microstructure, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

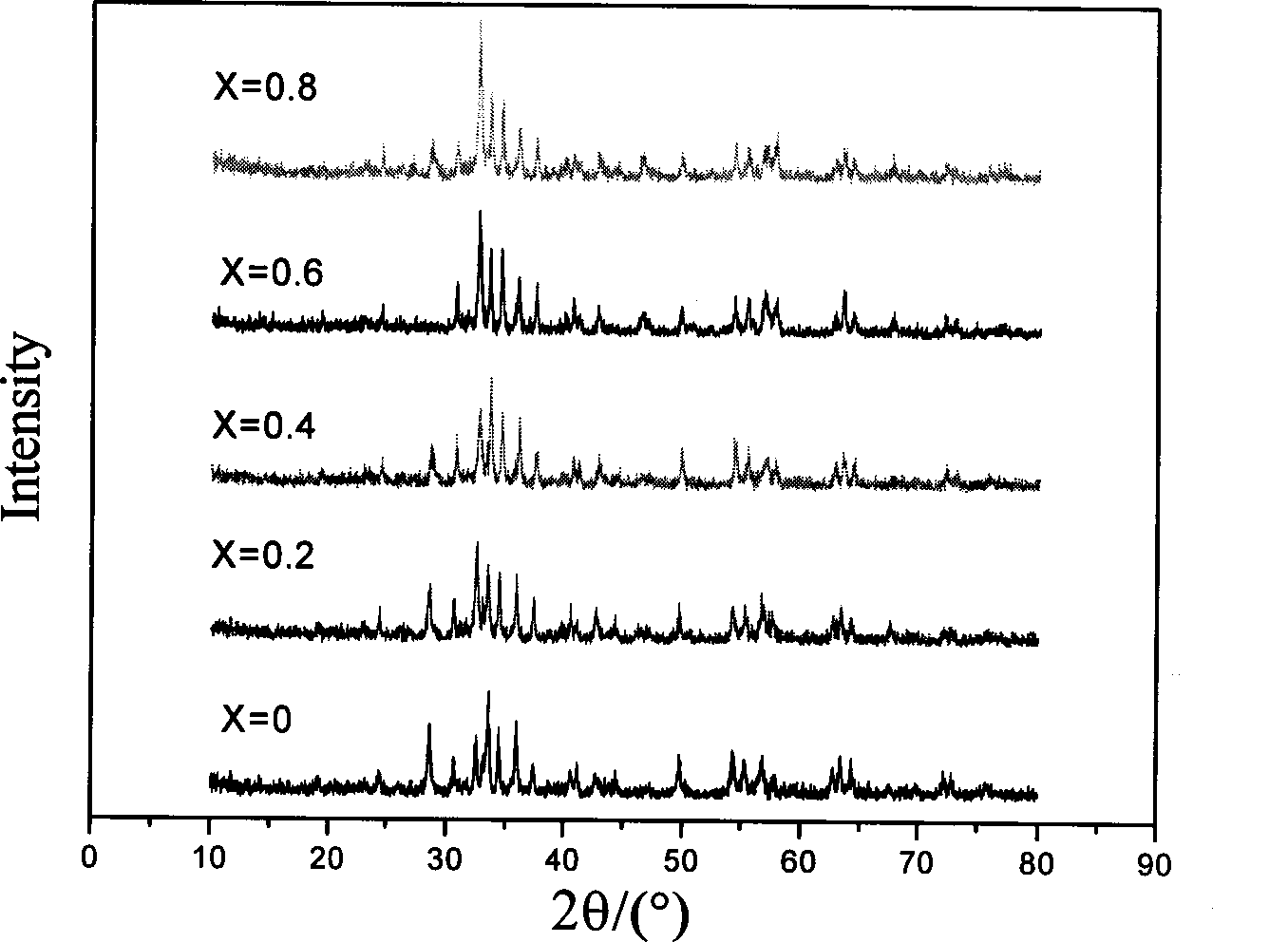

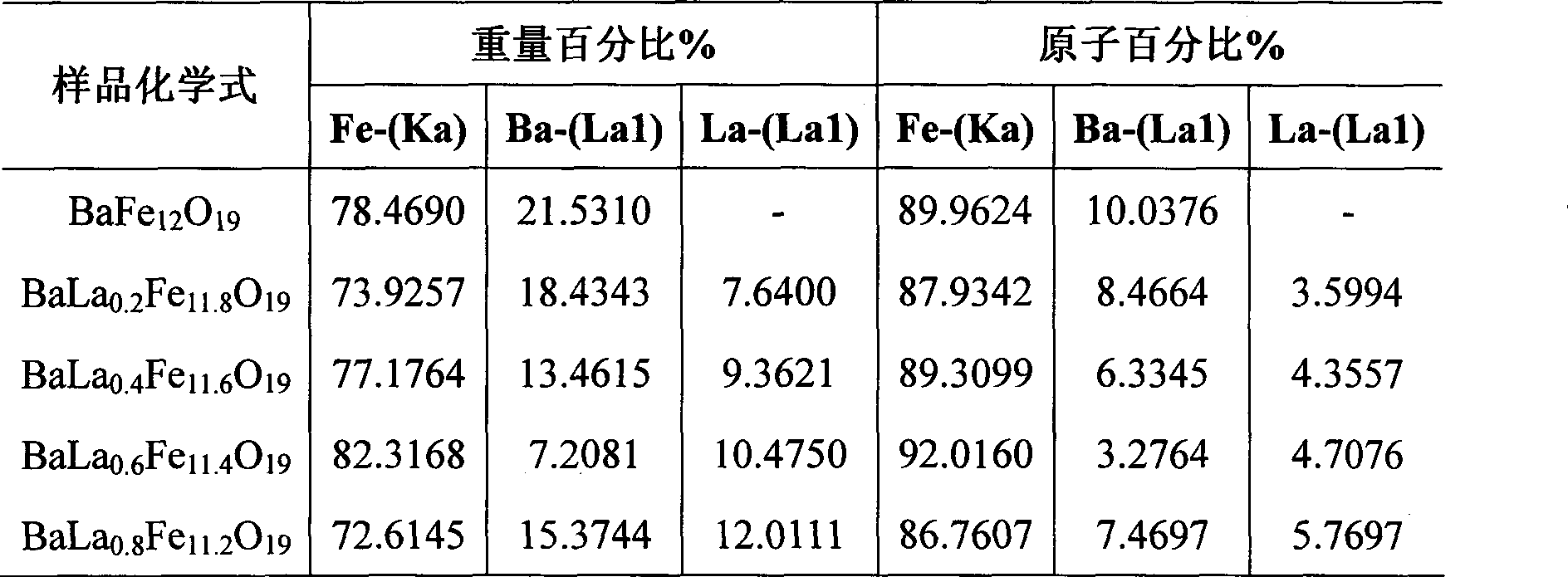

[0026] This experiment is to prepare a rare earth lanthanum-doped nano-barium ferrite film with a ratio of La / Ba=0.2. The specific steps are as follows:

[0027] 1. Put barium nitrate (0.5g) and lanthanum nitrate (0.1243g) into beaker A, add 200ml of distilled water to make the solution viscosity 2-4mPa·s, stir until completely dissolved;

[0028] 2. Put the main salt ferric nitrate (6.956g) into the B beaker, add 200ml of distilled water to make the solution viscosity 2-4mPa·s, stir until completely dissolved;

[0029] 3. Add citric acid (10.252g) into the B beaker and stir until completely dissolved;

[0030] 4. Put the beaker A into the beaker B, and stir for 5 minutes; slowly add ethylene glycol (5.44ml), continue to stir and control the temperature between 70°C, and slowly evaporate to obtain the sol;

[0031] 5. Soak the silica substrate in the sol, and use the dipping-pulling method to coat the film; pull it out of the liquid surface vertically at a rate of 2mm / s to fo...

Embodiment 2

[0036] This experiment is to prepare a rare earth lanthanum-doped nano-barium ferrite film with a ratio of La / Ba=0.4. The specific steps are as follows:

[0037] 1. Put barium nitrate (0.5g) and lanthanum nitrate (0.2486g) into beaker A, add 200ml of distilled water to make the solution viscosity 2-4mPas, stir until completely dissolved;

[0038] 2. Put the main salt ferric nitrate (6.956g) into the B beaker, add 200ml of distilled water to make the solution viscosity 2-4mPa·s, stir until completely dissolved;

[0039] 3. Add citric acid (10.453g) into beaker B and stir until completely dissolved;

[0040] 4. Put the beaker A into the beaker B and stir for 5 minutes; slowly add ethylene glycol (5.55ml), continue to stir and keep the temperature between 80°C and evaporate slowly to obtain a sol with a suitable viscosity;

[0041] 5. Soak the silica substrate in the sol, and use the dipping-pulling method to coat the film; pull it up and out of the liquid surface at a rate of 2...

Embodiment 3

[0046] This embodiment is to prepare a rare earth lanthanum-doped nano-barium ferrite film with a ratio of La / Ba=0.6, and the specific steps are as follows:

[0047] 1. Put barium nitrate (0.5g) and lanthanum nitrate (0.3729g) into beaker A, add 200ml of distilled water to make the solution viscosity 2-4mPa·s, stir until completely dissolved;

[0048] 2. Put the main salt ferric nitrate (6.956g) into the B beaker, add 200ml of distilled water to make the solution viscosity 2-4mPa·s, stir until completely dissolved;

[0049] 3. Add citric acid (10.654g) into the B beaker and stir until completely dissolved;

[0050] 4. Put the beaker A into the beaker B, stir for 5 minutes; slowly add ethylene glycol (5.65ml), continue to stir and keep the temperature between 75°C, evaporate slowly to obtain a sol with a suitable viscosity;

[0051] 5. Soak the silica substrate in the sol, and use the dipping-pulling method to coat the film; pull it out of the liquid surface vertically at a ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com