Nanometer hierarchical pore MFI molecular sieve one-step synthesis method

A microporous molecular sieve and molecular sieve technology, applied in the direction of crystalline aluminosilicate zeolite, borane silicone crystalline aluminosilicate zeolite, etc., can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

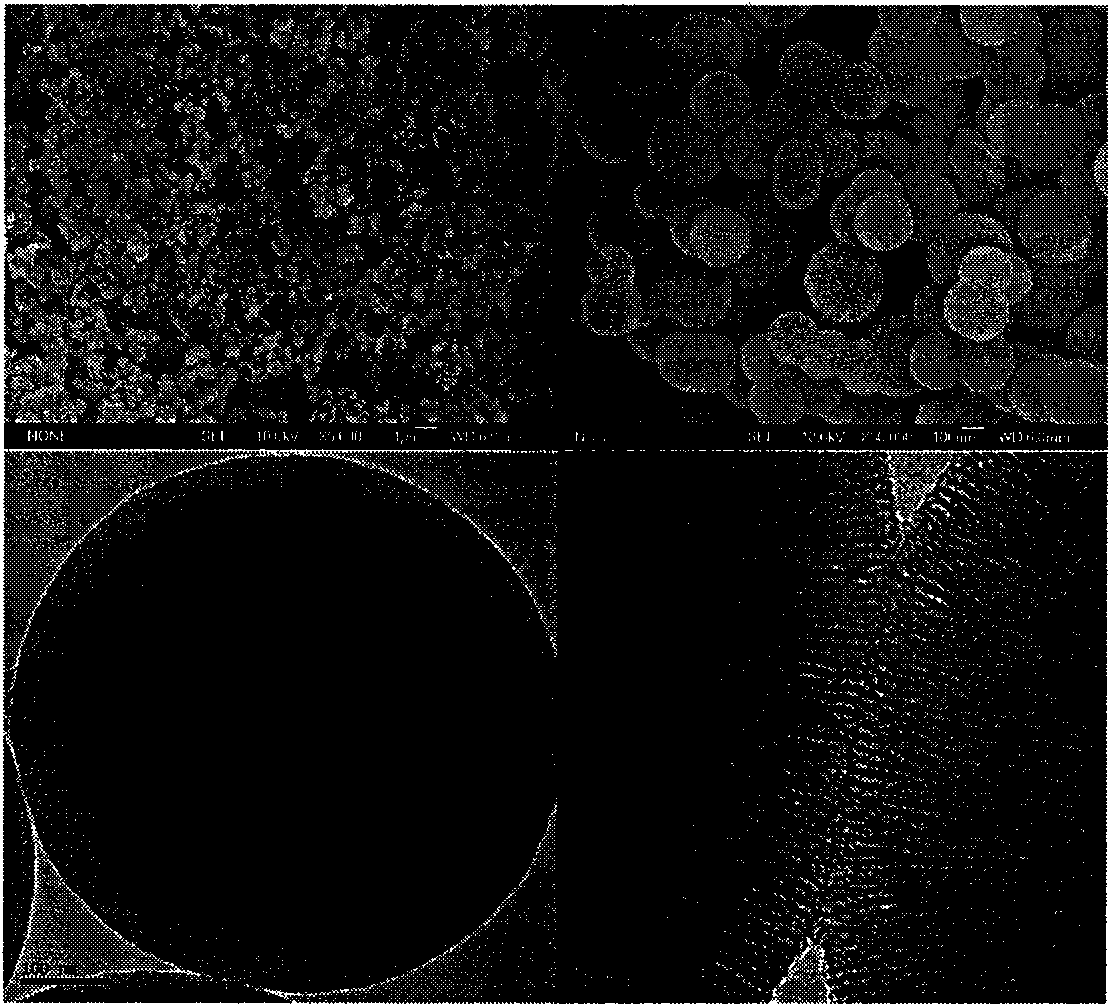

[0005] The preparation method of the multi-level porous molecular sieve material of the present invention is characterized by the following steps: preparing a certain concentration of fluorocarbon surfactant and hydrocarbon surfactant solution. Under water bath conditions, tetrapropylammonium hydroxide was added. Maintain the temperature of the water bath, add silicon source, aluminum source or titanium source while vigorously stirring, and maintain for a certain period of time. The obtained sol is moved into a stainless steel reaction kettle lined with polytetrafluoroethylene, and crystallized at a certain temperature for a period of time; the obtained solid is centrifuged, washed with deionized water, dried, and finally roasted to remove the template agent.

[0006] The characteristic of the mixed solution of the fluorocarbon surfactant and the hydrocarbon surfactant is that the molar ratio of the fluorocarbon surfactant to the hydrocarbon surfactant is 0.16-1.0, preferably ...

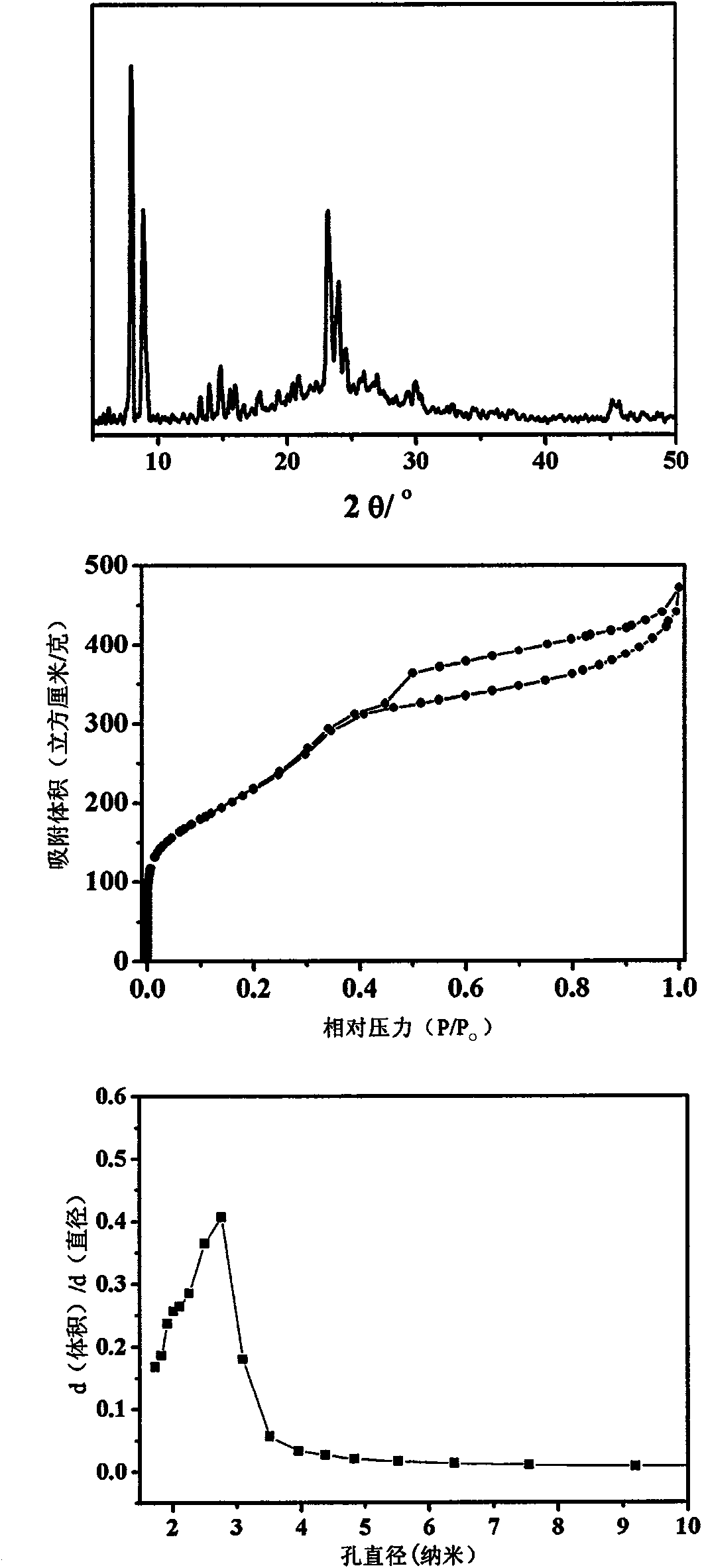

Embodiment 1

[0014] Dissolve 0.3 g of cetyltrimethylammonium bromide and 0.4 g of FSO-100 in deionized water. After a uniform solution was formed, 1.0ml of tetrapropylammonium hydroxide (mass percentage: 25%) was added, the temperature was raised to 35°C, 1.57g of sodium silicate was added, and vigorously stirred for 0.5h. The obtained sol was transferred into a stainless steel crystallization kettle and treated with hydrothermal treatment at 140°C for 5d. After centrifugation, the precipitate was dried overnight at 100°C, and then baked in a muffle furnace at 650°C for 6 hours to obtain the desired material. The specific surface area is 786m 2 / g, the total pore volume is: 0.68cm 3 / g, micropore area 173m 2 / g.

Embodiment 2

[0016] Dissolve 0.2 g of sodium dodecylbenzenesulfonate and 0.3 g of FC-4 in deionized water. After a uniform solution was formed, 4.0ml of tetrapropylammonium hydroxide (25% by mass) was added, the temperature was raised to 80°C, 1.108g of ethyl orthosilicate and 0.05g of tetrabutyl titanate were added, and vigorously stirred for 24h. The obtained sol was transferred into a stainless steel crystallization tank and treated with hydrothermal treatment at 180°C for 1d. After centrifugation, the precipitate was dried overnight at 100°C, and then baked in a muffle furnace at 650°C for 6 hours to obtain the desired material. The specific surface area is 897m 2 / g, the total pore volume is: 0.87cm 3 / g, micropore area 86m 2 / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com