Epoxidation catalyst preparation method and prepared epoxidation catalyst thereof, and applications of epoxidation catalyst

A catalyst and epoxidation technology, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of low reactivity of titanium-based catalysts and achieve improved Stability, the effect of high hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

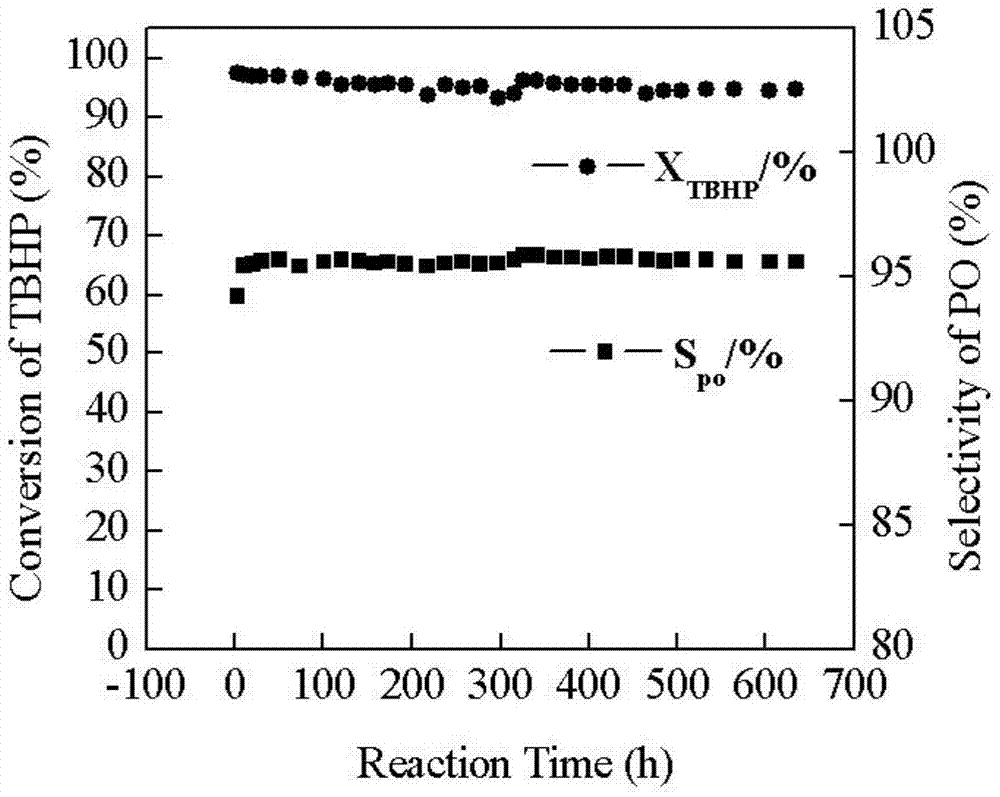

Examples

Embodiment 1

[0077] Step (1): 100g silica gel (Megao Chemical SG08-1, specific surface area 300m 2 / g, average pore diameter 11nm) into a quartz fixed-bed reactor, heat the bed to 120 ° C, N 2 The flow rate is 0.5L / min, purging and drying for 2h, adding 5g of titanium tetrachloride into a 100ml three-neck flask, heating to 140°C, using 0.5L / minN 2 As a carrier gas, titanium tetrachloride vapor was introduced, and the introduction of titanium tetrachloride vapor was stopped after 2 hours.

[0078] Step (2): Heat the bed temperature to 190°C, using 0.5L / min N 2 As a carrier gas, 5 g of hexamethyldisilamine gas was introduced for 2 hours.

[0079] Step (3): maintain bed temperature at 190°C, N 2 Purge for 2h.

[0080] Step (4): Raise the bed temperature to 340° C., feed steam at a rate of 0.3 g / (h·gcat), and feed steam for 2 hours.

[0081] Step (5): Add the product obtained in step (4), 3 g of molybdenum dioxide dichloride, to 400 g of p-dichlorobenzene, heat to 180°C, condense and refl...

Embodiment 2

[0085] Except that the consumption of step (1) titanium tetrachloride is 2g, molybdenum dioxide dichloride 2.1g in step (5), all the other conditions are the same as embodiment 1. Obtained 2# epoxidation catalyst, its titanium content is 0.5wt%, molybdenum content is 1wt%.

Embodiment 3

[0087] Except that the consumption of step (1) titanium tetrachloride is 6g, molybdenum dioxide dichloride 2.1g in step (5), all the other conditions are the same as embodiment 1. Obtained 3# epoxidation catalyst, its titanium content is 1.5wt%, molybdenum content is 1wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com