Scrape-prevention heat transfer film and preparation method thereof

A technology of thermal transfer film and production method, applied in the direction of temperature recording method, etc., can solve the problems of peeling, weak surface scratch resistance, poor hardness of release gold oil layer, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

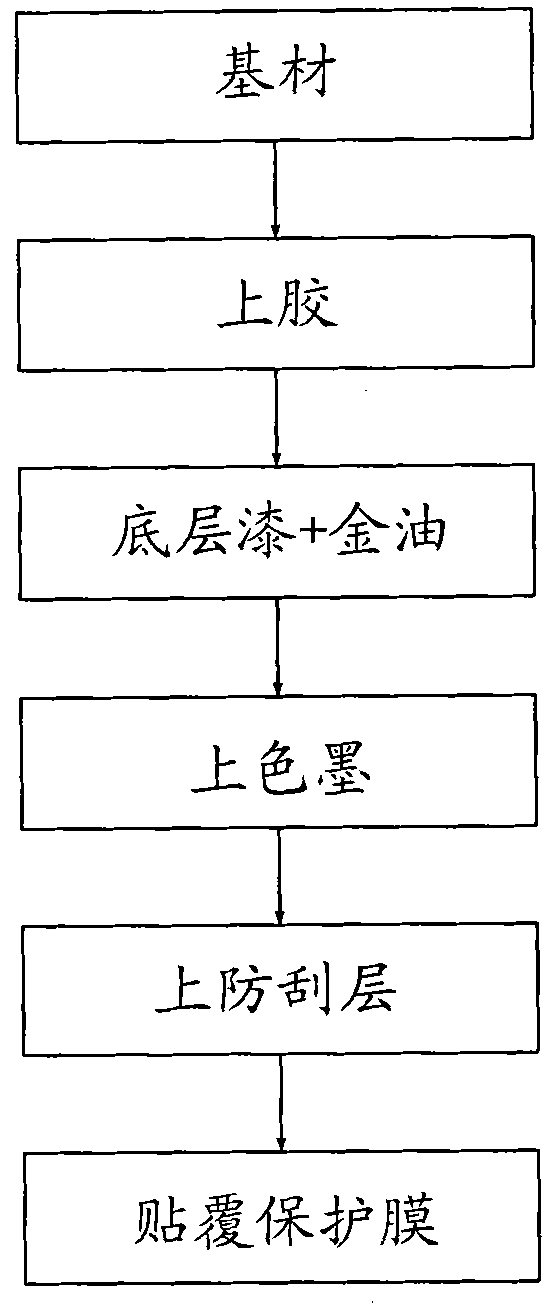

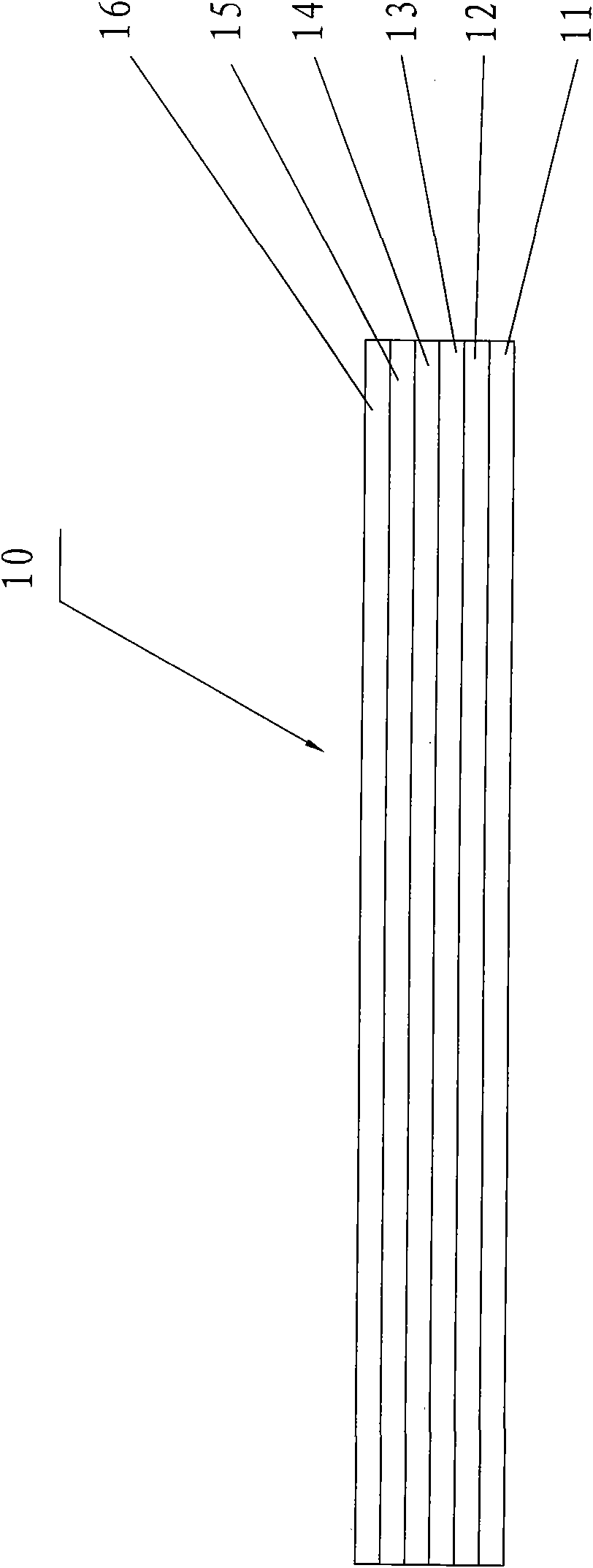

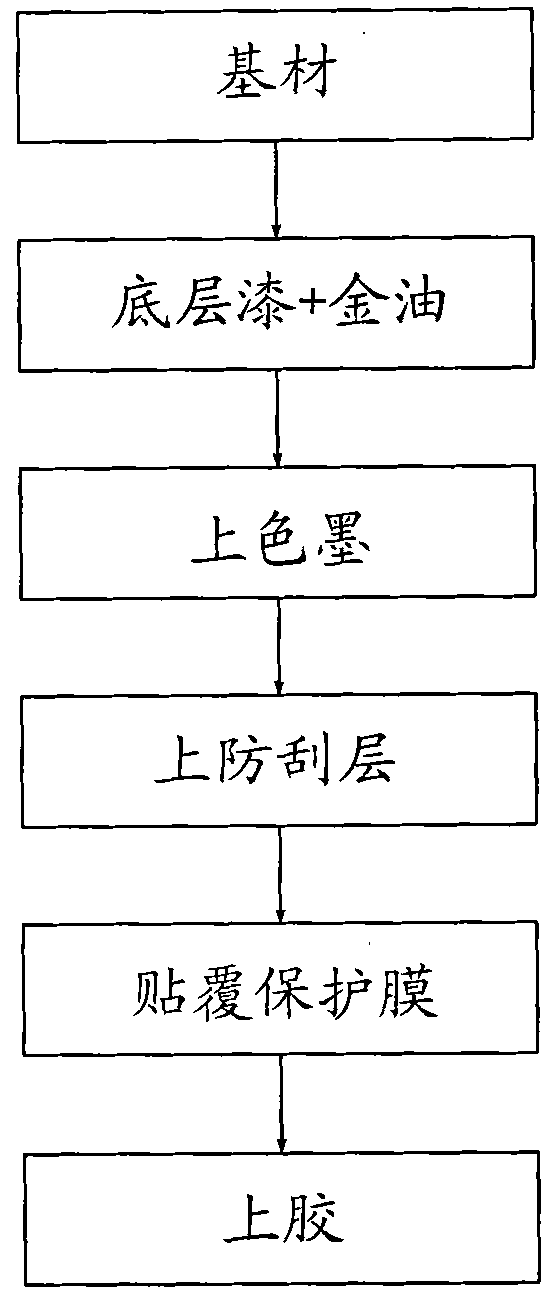

[0031] See first figure 1 and figure 2 As shown, the present invention provides a method for making a scratch-resistant thermal transfer film 10, the steps of which include:

[0032] (1) Base material: The base material is anti-adhesive release paper 11, or a polar material with a plastic film on the surface, which has anti-adhesive properties, and the release paper 11 or polar material has the ability to be recycled and reused. characteristic;

[0033] (2) Gluing: hot-melt glue is printed on the surface of the release paper 11 to form a hot-melt glue layer 12 for attaching to the attachment layer of the product;

[0034] (3) Primer paint and gold oil: print or spray print primer 13 on the surface of the hot melt adhesive layer 12, the primer 13 can be white, black or other colors, etc., depending on the color of the ink layer 14 , as a substrate, and add appropriate gold oil to mix each other, so that the affinity between the primer 13 and the hot melt adhesive layer 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com