Vacuum ampoule fusion sealing machine

An ampoule and vacuum technology, which is used in glass re-molding, glass manufacturing equipment, glass molding, etc., can solve the problems of vacuum sealing machine not being able to perform vacuum sealing, high sealing qualification rate, difficult to achieve, etc. Simple, high pass rate, easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

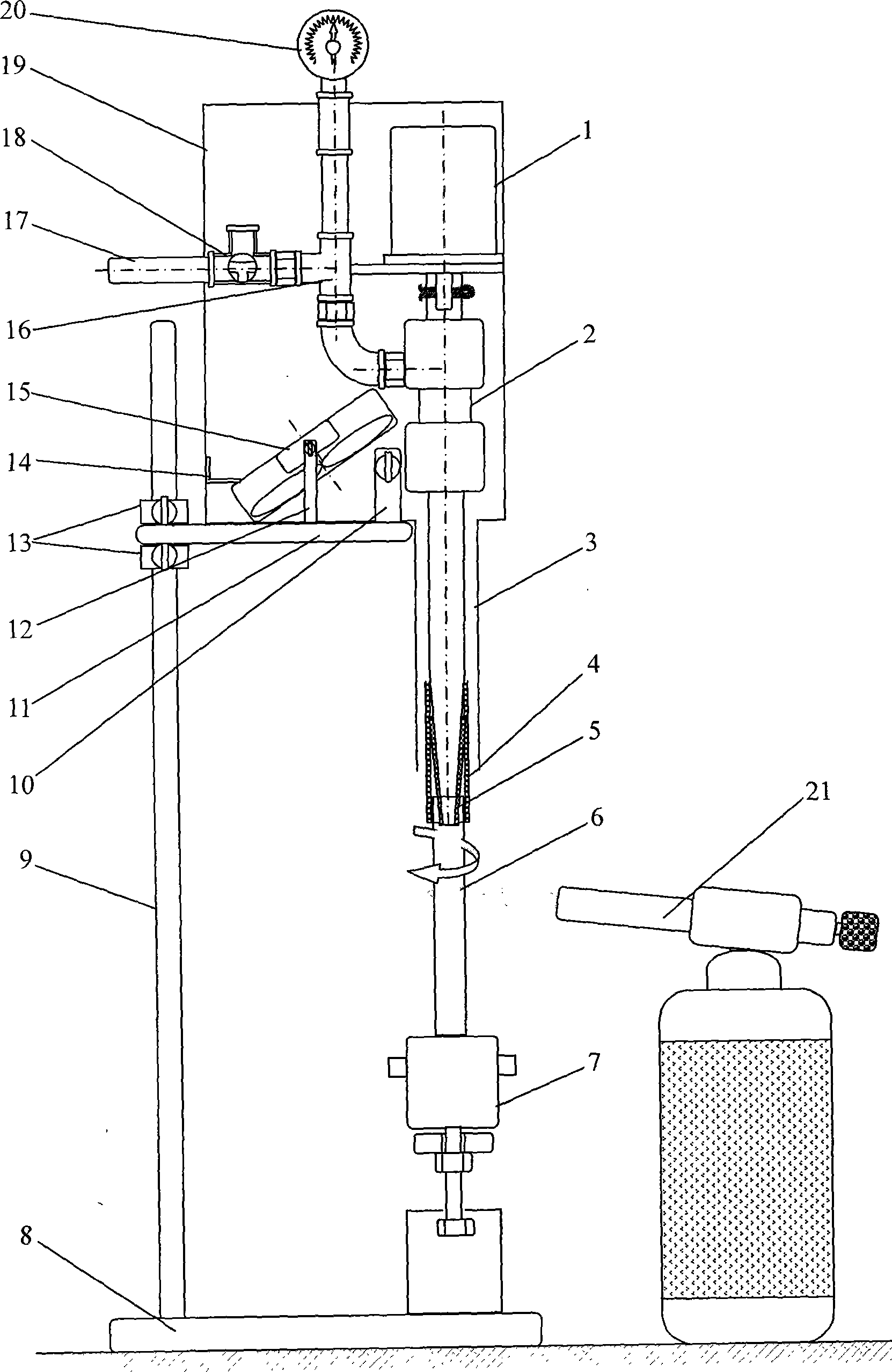

[0027] See Figure 1 ~ Figure 4 , Is the vacuum ampoule melting-sealing machine in the vertical-position melting-sealing mode of the present invention. The melting-sealing machine is provided with a rotary vacuum connector 2 connected to the rotary drive mechanism 1 and a gravity-stretching rotary ampoule or test tube clamp 7 between the rotary vacuum connector 2 and the gravity-stretching rotary ampoule or test tube clamp 7 A high-temperature gas blowtorch 21 as a melting and sealing heating device is provided.

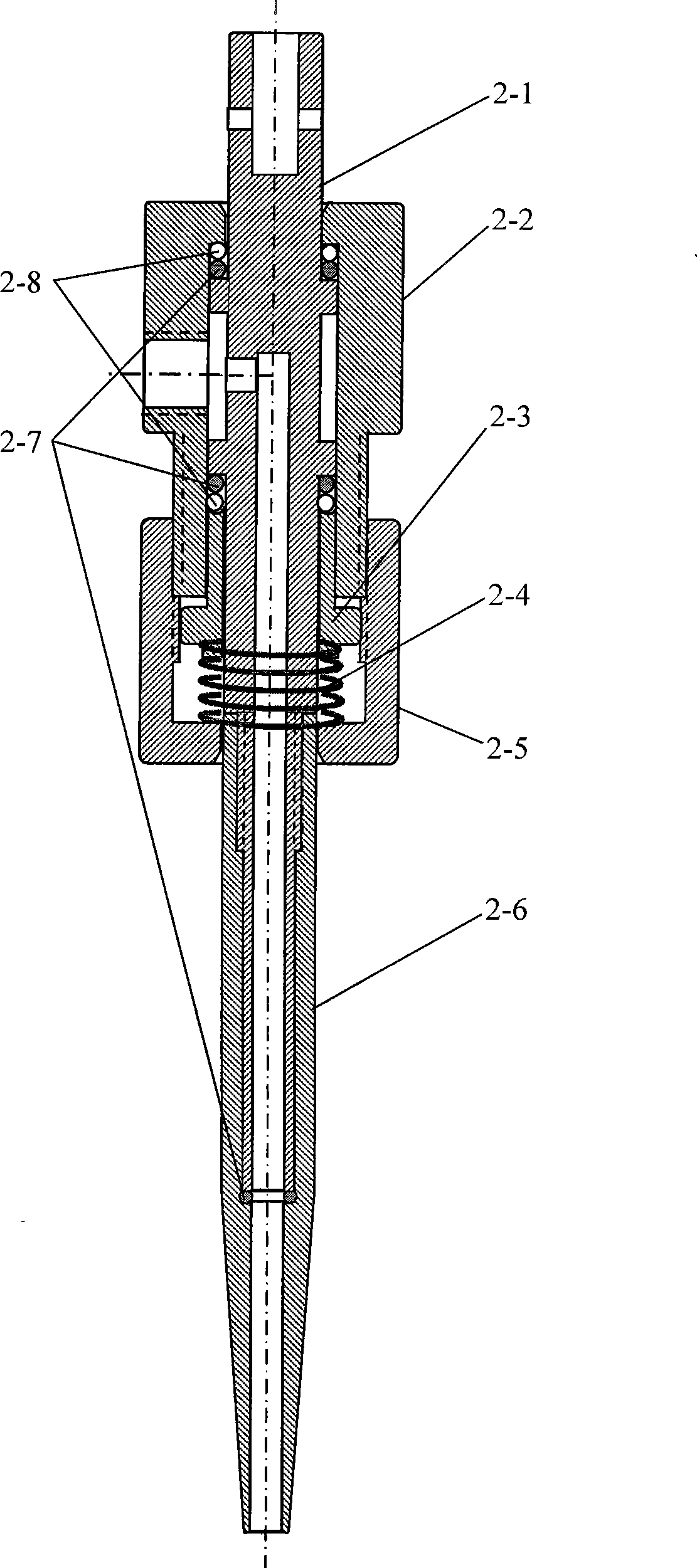

[0028] The structure of the rotary vacuum connector 2 is: a rotary vacuum connecting shaft 2-1 is provided, one end is connected with the permanent magnet synchronous low-speed motor 1 as a rotary drive mechanism, and the other end is threaded with the rotary vacuum suction head 2-6 Connected to the "O"-shaped sealing ring, with a fixed shaft sleeve 2-2 in the middle, and a ball 2-8, "O" shape between the fixed shaft sleeve 2-2 and the rotary vacuum connecting shaft 2-1 ...

Embodiment 2

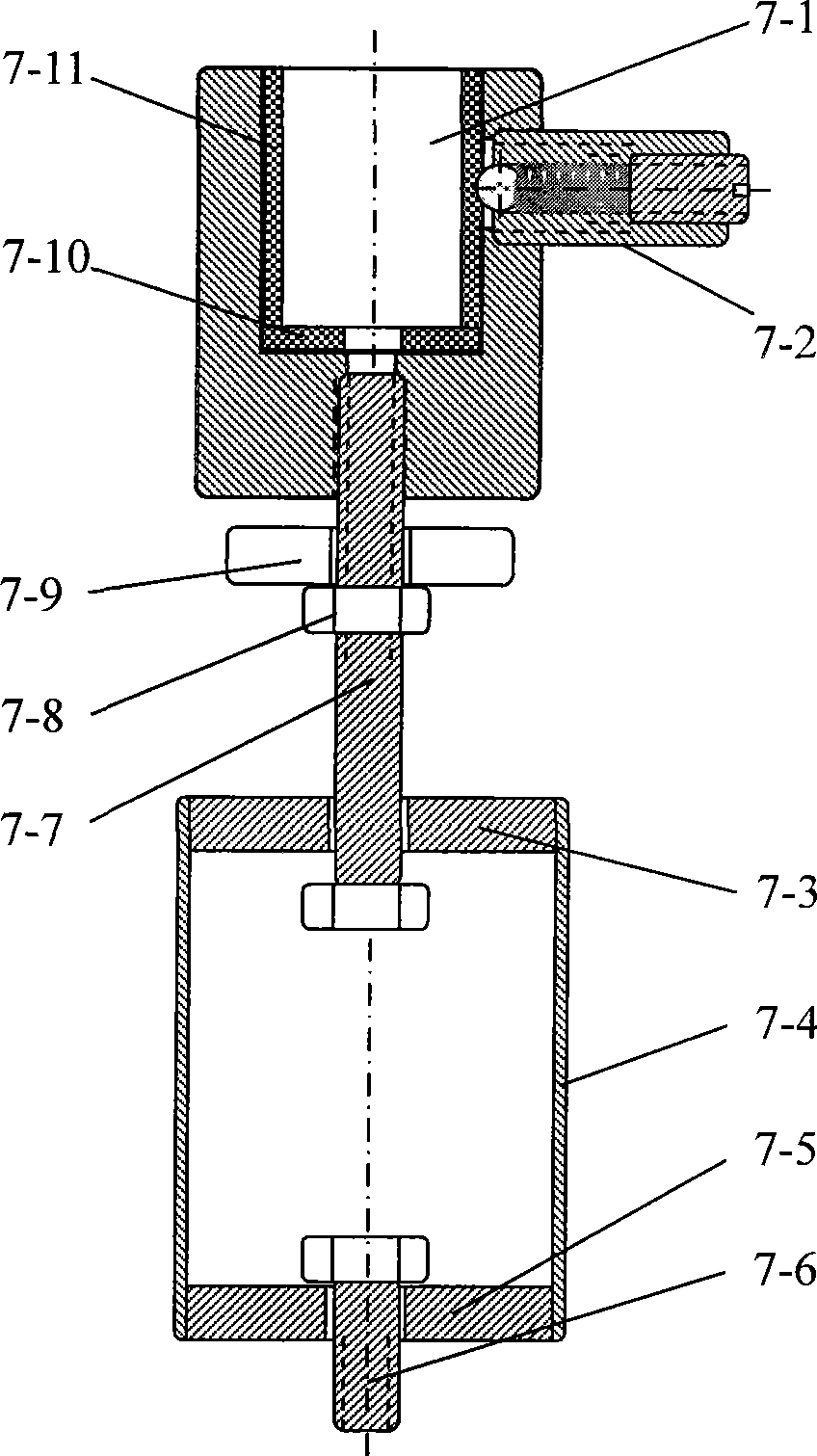

[0035] See Figure 5 ~ Figure 6 , The vacuum ampoule melting and sealing machine in this example is horizontal or inclined, and the inclination angle can be adjusted as required. The rotary stretch type ampoule or test tube clamp is a spring force stretch type ampoule or test tube clamp 22, and its structure is: a rotary type ampoule or test tube slot 7-1 is provided, and the rotary type ampoule or test tube slot 7-1 is inside Equipped with rubber protective tube 7-11 and rubber protective pad 7-10, the side of the slot is provided with 3 screw tube bumper type top wires 7-2 for tightening the ampoule or test tube; rotary ampoule or test tube slot 7 The bottom of -1 is connected to one end of the spring rod 22-10 through the bearing 22-12, and the other end of the spring rod 22-10 with the return spring 22-9 passes through the bearing cover 22-11 and extends into the spring slide groove 22-4 ; One end of the return spring 22-9 rests on the bottom of the slide groove 22-4, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com