Concrete waste recycling device and method

A technology for concrete waste and reuse, which is applied in the directions of cleaning methods, heating devices, cleaning methods and utensils using liquids, which can solve the problem of affecting the bonding strength of the interface between gel materials and aggregates, affecting the quality of finished concrete, and affecting regeneration. Concrete coarse aggregate and fine aggregate ratio and other issues to achieve the effect of ensuring dryness, ensuring cleanliness, and preventing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

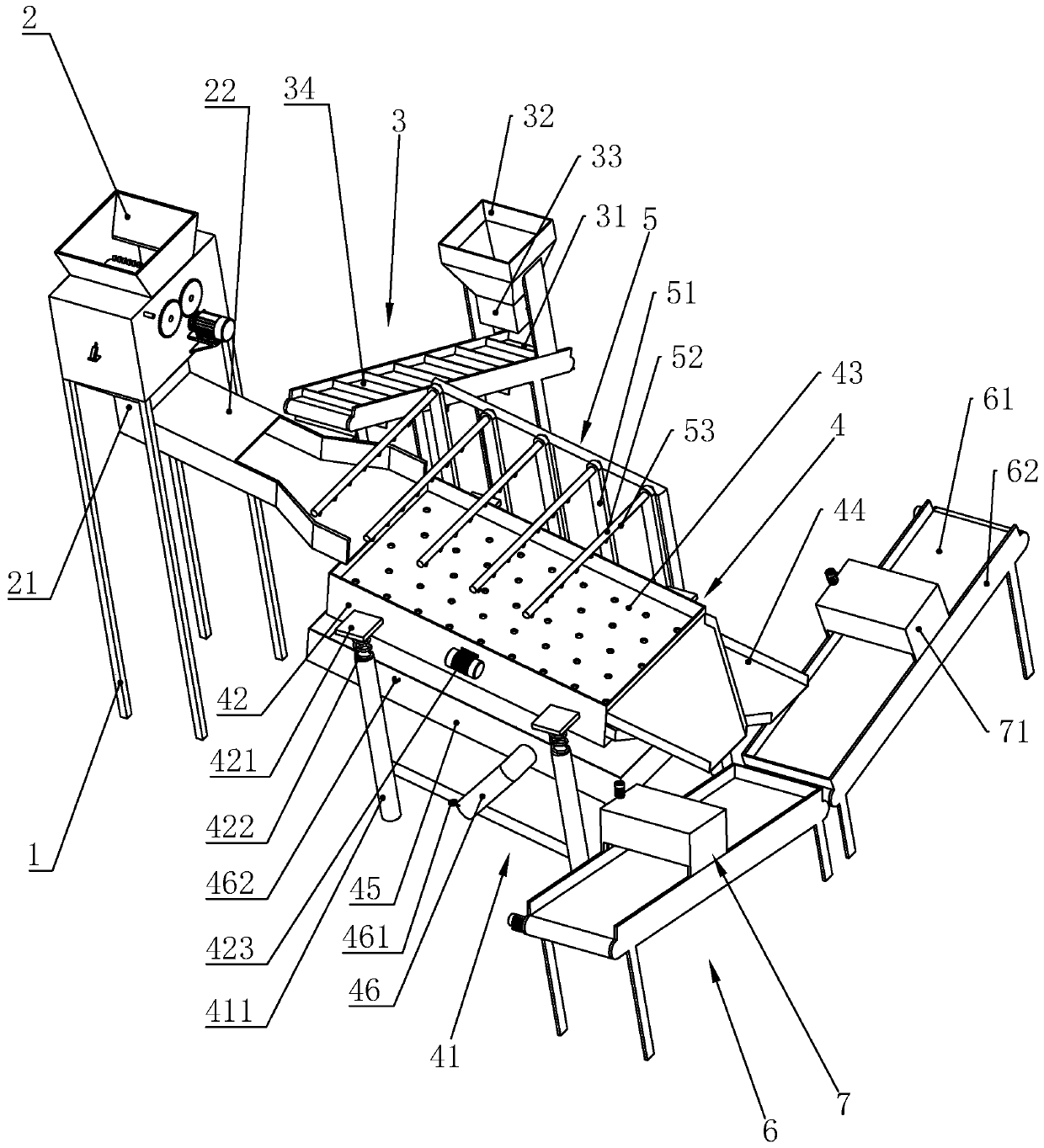

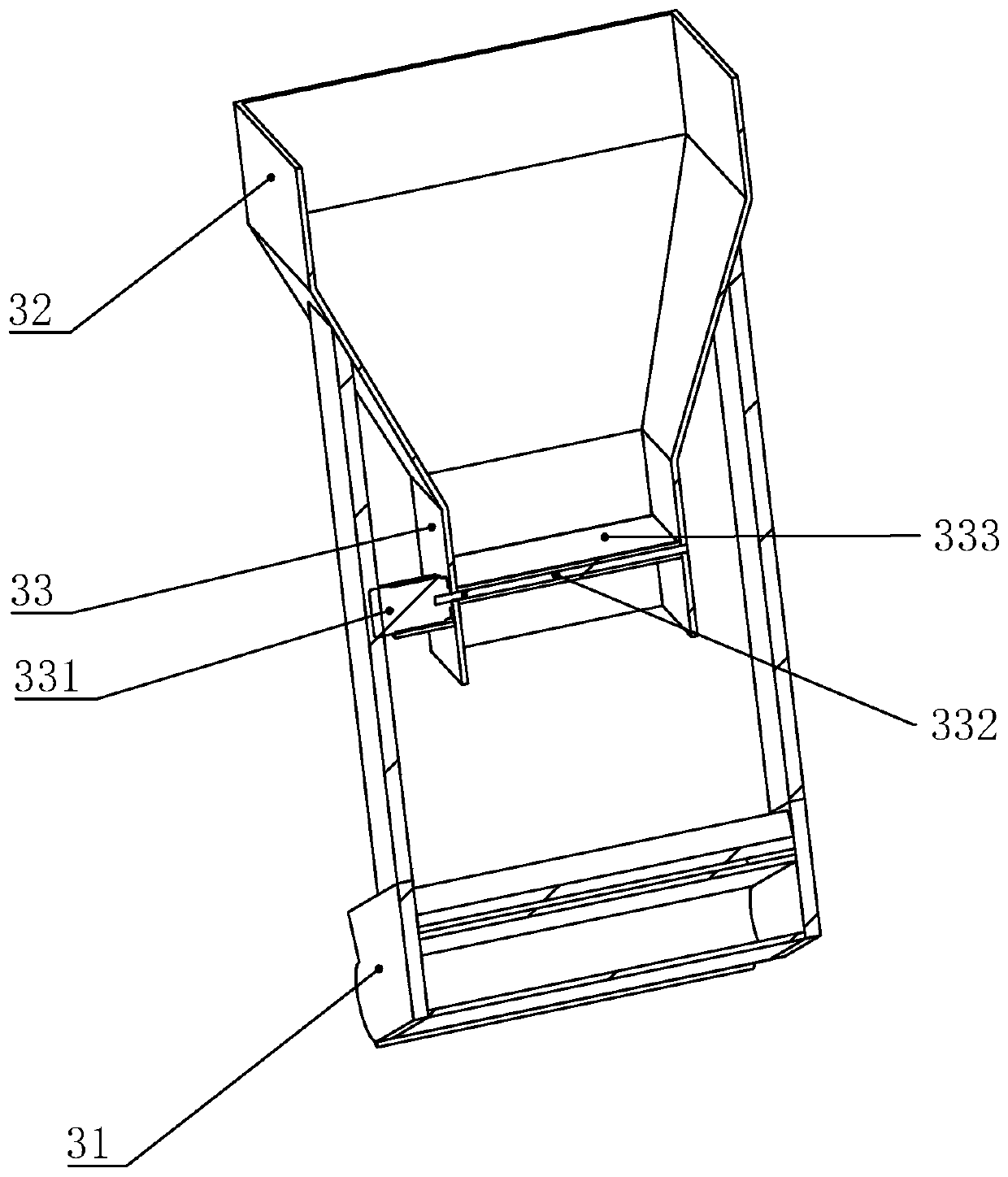

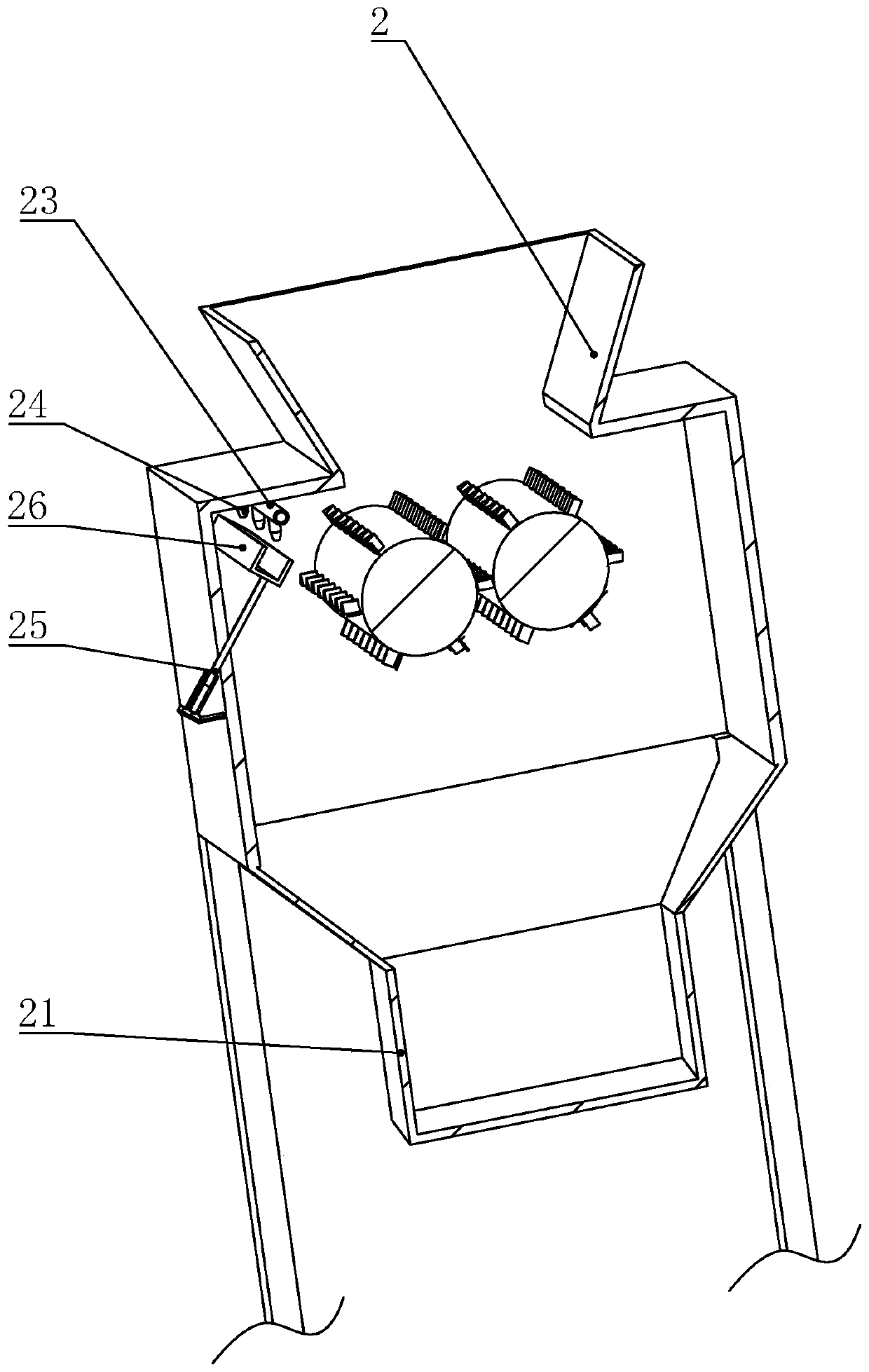

[0040] refer to figure 1 , is a concrete waste recycling device disclosed by the present invention, comprising a first bracket 1 and a crusher 2 arranged on the top thereof, a screening machine 4 is provided on one side of the crusher 2, and a discharge port 21 at the bottom of the crusher 2 is below There is a material guide trough 22 inclined between the feed end of the screening machine 4, the end of the material guide chute 22 close to the crusher 2 is higher than the end close to the sieving machine 4, and the side of the material guide chute 22 is tilted with a feeding mechanism 3, The higher end of the feeding mechanism 3 is located above the material guide trough 22. The screening machine 4 includes a second bracket 41 and a U-shaped bracket 42 arranged on the top of the second bracket 41. 2. At one end, the side wall of the U-shaped fixed frame 42 is protruded with a fixed plate 421, and a spring 422 is provided between the top of the leg 411 of the second support 41 ...

Embodiment 2

[0046] A method for reusing concrete waste, comprising the steps of:

[0047] S1: Throw the tested concrete test block into the crusher 2 for crushing;

[0048] S2: The materials or concrete leftovers crushed by the crusher 2 are screened and cleaned at the screening machine 4;

[0049] S3: The screened and cleaned materials are transported to a fixed location for storage via the first conveyor belt 61, and are dried when passing through the drying mechanism 7.

[0050] The aggregates are cleaned while being screened, and the aggregates are dried while being transported. This ensures dry and clean aggregates while shortening the processing flow and is easy to operate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com