Full-automatic horizontal type food packer

A food packaging, fully automatic technology, used in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of complex structure, loose horizontal sealing, defective products and waste products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

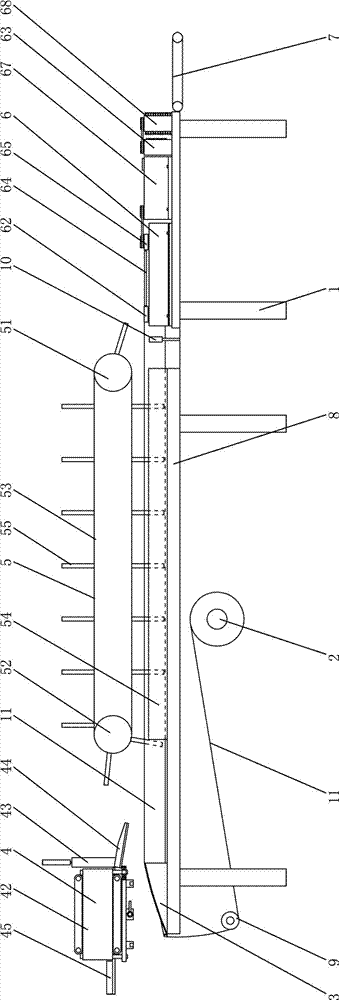

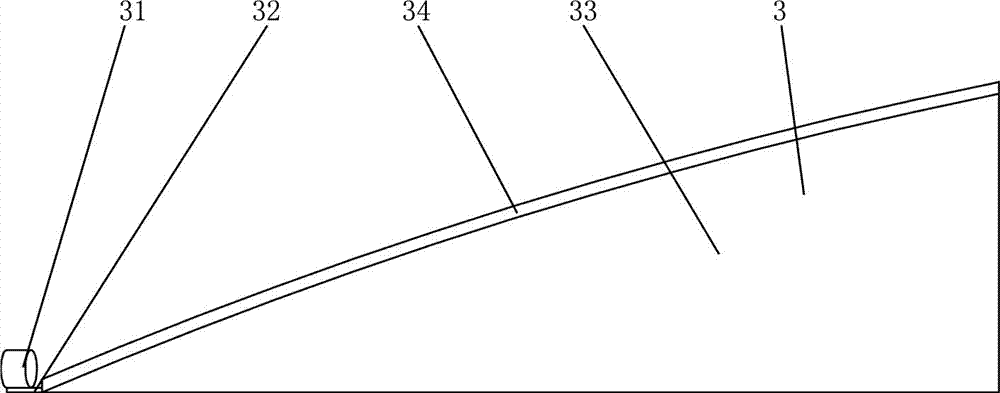

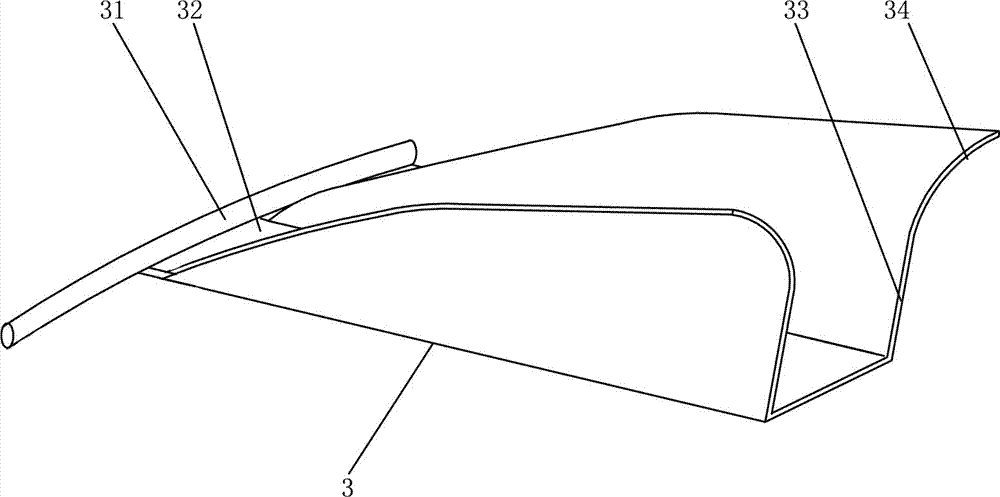

[0047] Such as figure 1 As shown, this fully automatic horizontal food packaging machine includes a frame 1, a packaging film unwinding device 2, a former 3, a feeding device 4, a positioning feeding device 5, a sealing device 6 and a discharge conveyor belt 7, the packaging film The unwinding device 2, the former 3, the feeding device 4, the positioning feeding device 5 and the sealing device 6 are arranged in sequence along the conveying direction of the packaging film, and the discharge conveyor belt 7 is arranged behind the sealing device 6.

[0048] refer to Figure 9 The positioning feeding device 5 includes a feeding motor, a driving sprocket 51, a driven sprocket 52, an endless chain 53 and a strip guide groove 54, and the driving sprocket 51 and the driven sprocket 52 can be rotatably mounted on the frame 1, The power output shaft of feeding motor is connected with driving sprocket 51 transmission, and the axis of driving sprocket 51 and driven sprocket 52 is all tow...

Embodiment 2

[0080] The shearing mechanism adopted in this embodiment is different from that in Embodiment 1. Such as Figure 13 As shown, in this embodiment, the cutting mechanism includes a first scissors blade 431', a first knife handle 432', a second scissors blade 433', a second knife handle 434', a pin shaft 435', a cam 436', a cam Drive motor and tension spring 437', the first scissors blade 431' tail is integrally connected with the first knife handle 432', the second scissors blade 433' tail is integrally connected with the second knife handle 434', and the pin shaft 435' is installed on the machine On the frame, the tail of the first scissors blade 431' and the tail of the second scissors blade 433' can be rotatably mounted on the pin shaft 435', and the cam 436' is between the first knife handle 432' and the second knife handle 434', The inner side of the first handle 432' and the inner side of the second handle 434' are matched with the contour of the cam 436', and the two end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com