High speed spindle box structure

A high-speed spindle and spindle technology, which is applied in the direction of large fixed members, metal processing machinery parts, maintenance and safety accessories, etc., can solve the problems that the bearing affects the speed and processing accuracy, and the cooling effect is not good, so as to ensure the processing accuracy and increase the speed , Guarantee the effect of rotation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

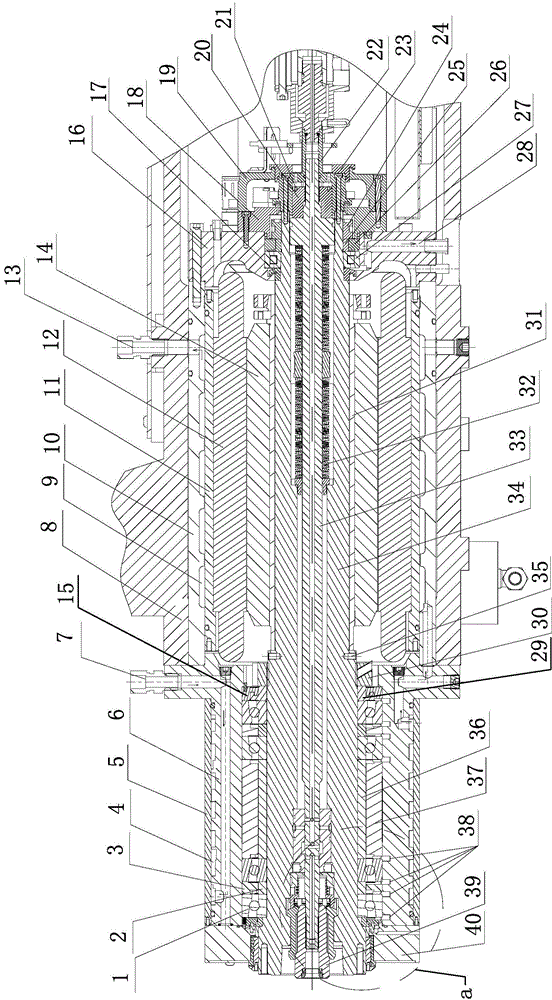

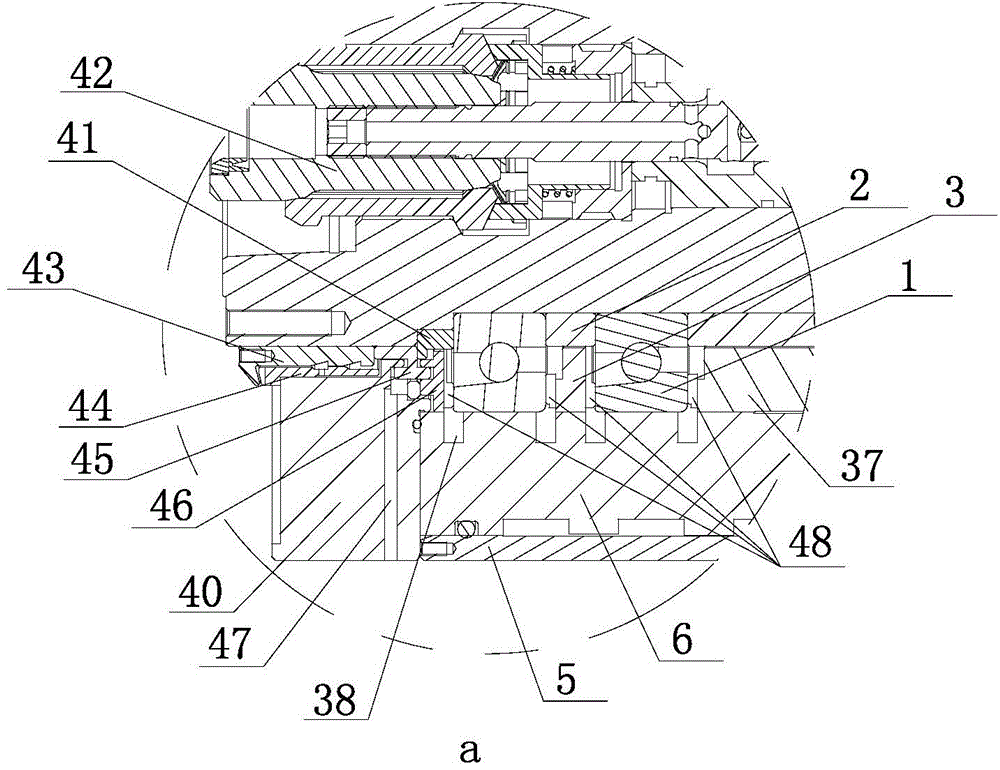

[0016] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

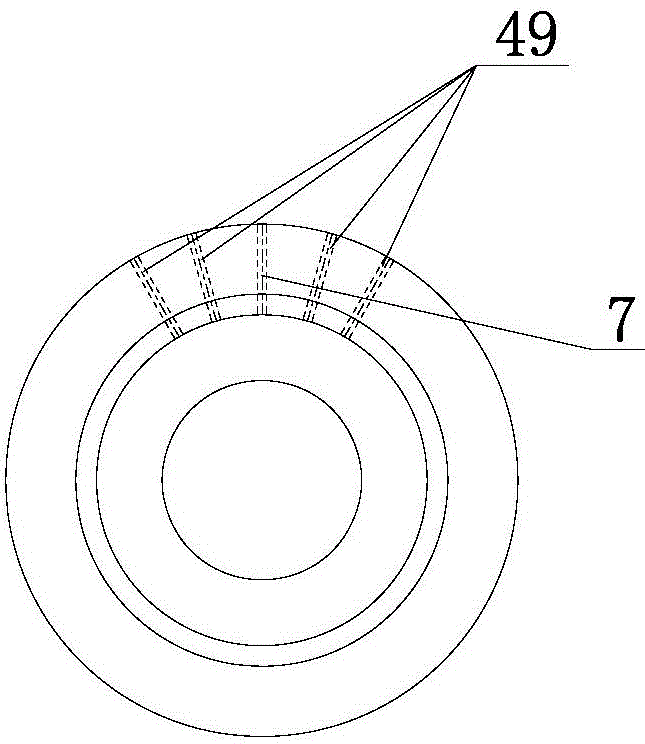

[0017] Such as Figure 1~Figure 6 As shown, the present invention includes a main shaft housing 8, a main shaft device, a front bearing seat 6, a rear bearing housing 16, a main shaft drive mechanism and a dynamic balance adjustment mechanism, the main shaft housing 8 is provided with a main shaft hole, and the main shaft The device comprises a hollow main shaft 34, a broach bar 33, a broach claw and a disc spring group 32, the main shaft 34 is worn in the main shaft hole, and the disc spring group 32, the broach claw 39 and the broach bar 33 are accommodated. Placed in the hollow inner cavity of the main shaft 34, the broach claw cover 42 is mounted on the front end of the broach rod 33, and the broach claw cover 42 is fixed between the broach claw 39 and the inner cavity wall at the front end of the main shaft 34. The butterfly spring group...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com