Front lifting crane and hydraulic steering system thereof

A technology of steering system and crane, applied in steering mechanism, fluid steering mechanism, steering mechanism of deflectable wheel, etc., can solve the problems of high use and maintenance cost, damaged rear wheel rim, aggravated front wheel wear, etc., and reduce use and maintenance. Cost, fatigue strength reduction, sliding friction reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The core of the present invention is to provide a steering system of a reach stacker crane to effectively take into account the requirements of its own performance and the service life of wheels. A detailed description will be given below in conjunction with the accompanying drawings of the description.

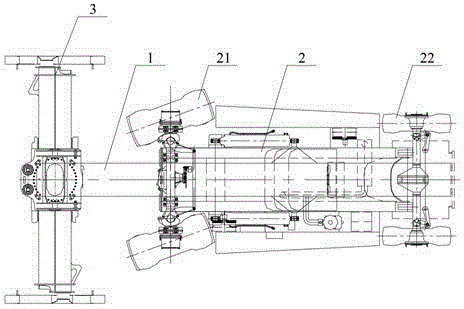

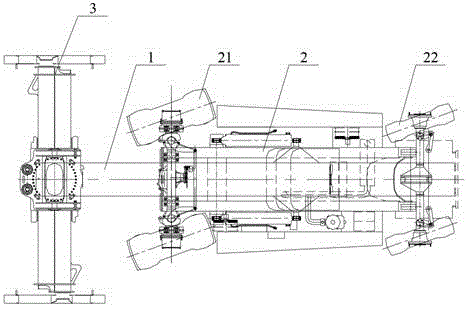

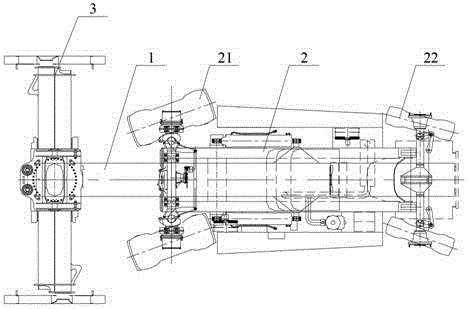

[0031] See figure 2 and image 3 ,in, figure 2 It is a schematic top view of the reach stacker crane described in this embodiment, image 3 It is a unit block diagram of the steering control system of the reach stacker crane according to this embodiment.

[0032] The main structure of the reach stacker crane is the same as that of the prior art. The arm frame 1 is arranged on the traveling chassis 2, and the boom can be carried out through the luffing cylinder (not shown) arranged between the arm frame 1 and the chassis 2. The working angle of the boom can be adjusted, and at the same time, the working length of the boom can be adjusted by setting the telescopic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com