On-machine detection device and detection method of worm gear pair transmission precision

A transmission precision and detection device technology, which is applied in gear tooth manufacturing devices, gear teeth, belts/chains/gears, etc., can solve problems such as installation errors, and achieve the effects of reasonable structure setting, convenient operation, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

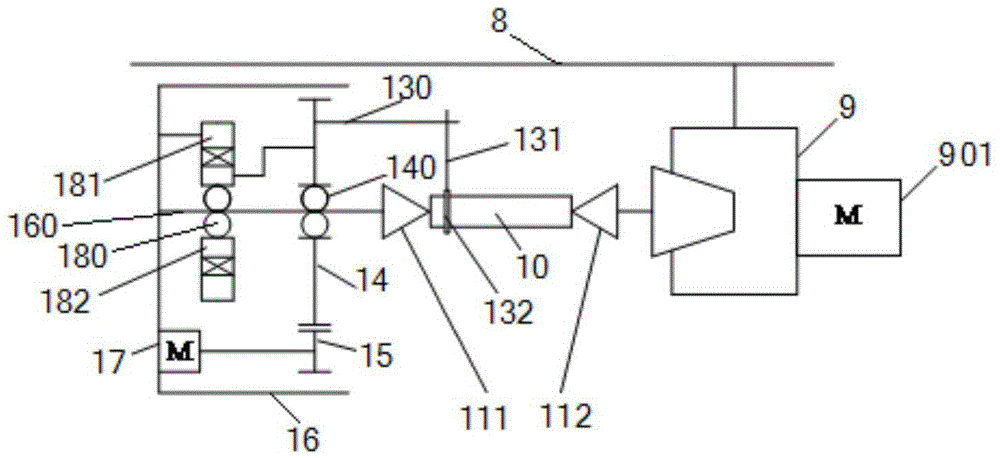

[0035] The worm tooling in the worm gear transmission accuracy clinical detection device of the present invention is used for the installation of the worm in the worm gear transmission accuracy detection, wherein the worm 10 is installed on the tooling, and the worm angular displacement sensor for detecting the rotation angle of the worm 10 is installed on the tooling . Such as figure 1 As shown, the frock has a bracket 16, a slide plate 8 above the bracket 16, and a pair of dead centers 111, 112 for supporting the two ends of the worm 10, wherein one dead center 111 is fixed on the bracket 16, and the other dead center 112 is fixed on the On the slide plate 8 , the two ends of the worm to be tested 10 are supported in the air by the dead centers 111 , 112 respectively, and the slide plate 8 can slide to adjust the distance between the two dead centers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com