a crushing station

A technology of crushing station and crushing device, applied in the field of construction machinery, can solve the problems of inconvenient horizontal and vertical swing of the discharge arm, poor structural stability, etc., to improve reliability and economy, increase stiffness, and improve structural stress. Well-distributed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

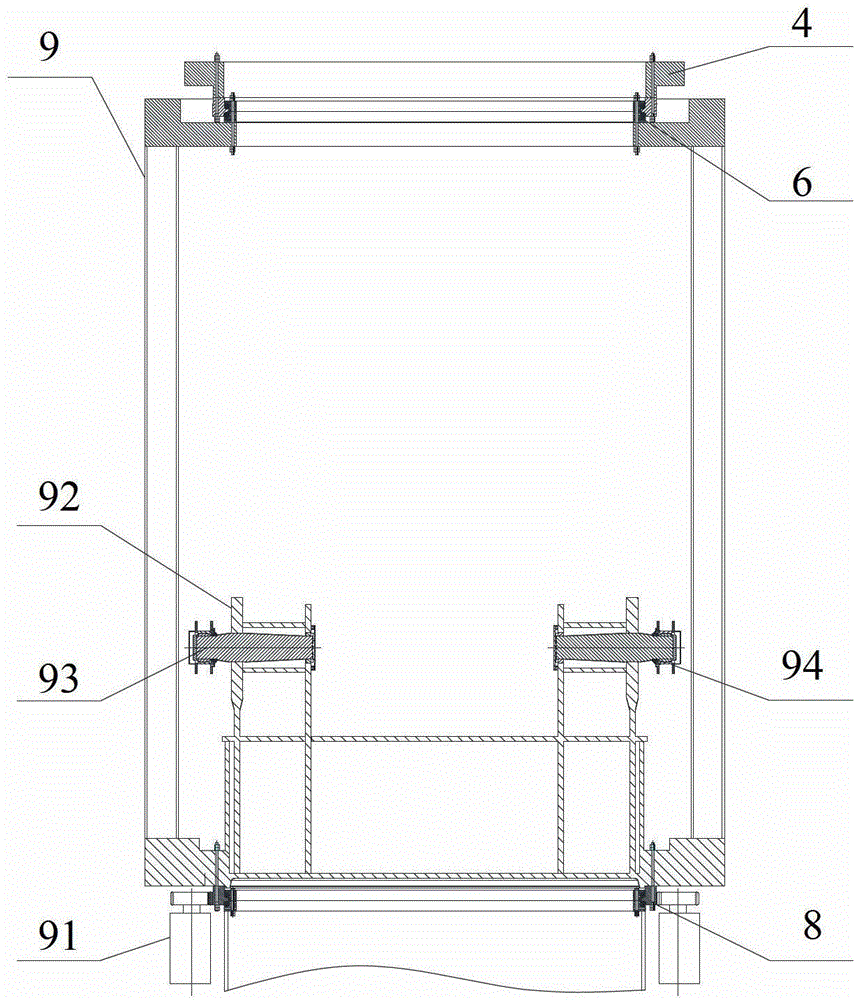

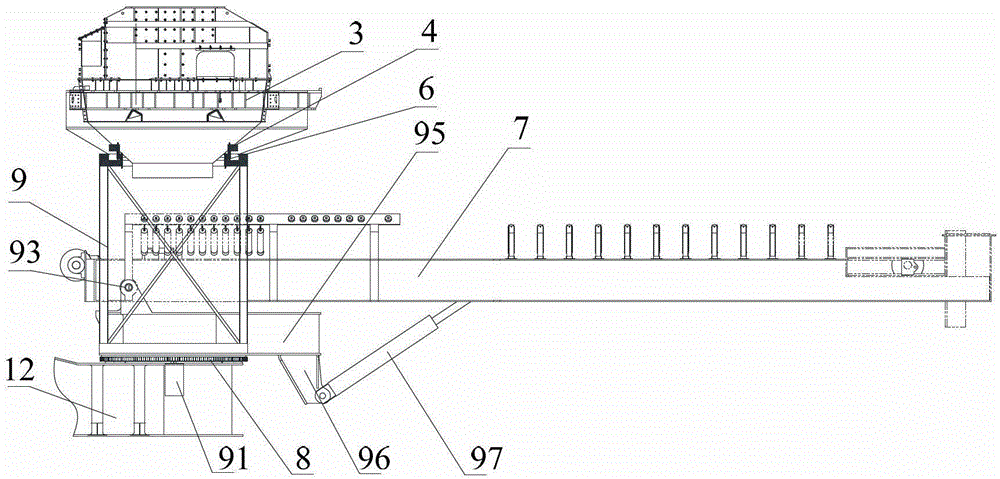

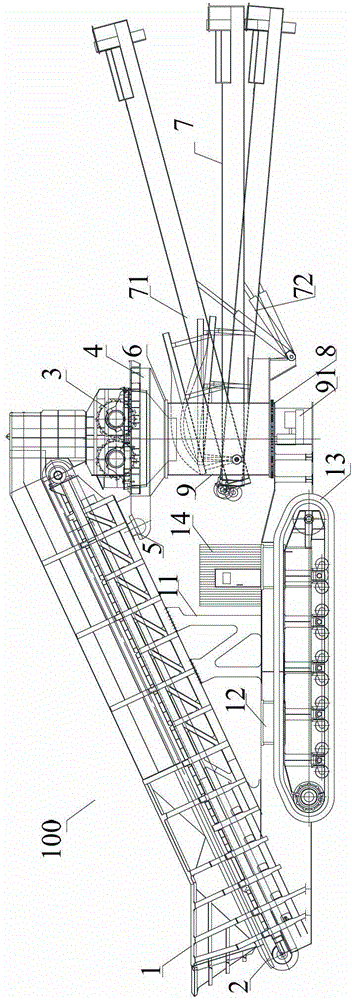

[0045] A crushing station 100 provided in the embodiment of the present invention, such as Figure 1-Figure 3 As shown, it includes: a loading and conveying device, a crushing device 3, an unloading and discharging device 7, a support mechanism and a supporting unit, wherein the charging and conveying device is used to hold materials to be crushed and transport the materials to be crushed; the crushing device 3 is connected to the loading and conveying device for crushing the materials to be crushed; the discharge and discharge device 7 is arranged at the outlet of the crushing device 3, and is used for discharging the crushed materials of the crushing device 3 and Unloading process; there is also a supporting mechanism arranged at the bottom of the crushing device 3, and the discharging and discharging device 7 is installed on the supporting mechanism; wherein, the supporting mechanism can drive the discharging and discharging device 7 to relatively crush The device 3 swings ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com