Vibration measuring instrument for super-large or super-heavy bearing

A bearing vibration and extra-heavy technology, which is applied in the direction of mechanical bearing testing, etc., can solve the problems that the rollers are not easy to rotate, easy to be damaged, and the sensor contacts are scratched, so as to ensure the rotation accuracy and improve the measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the technical solutions and accompanying drawings.

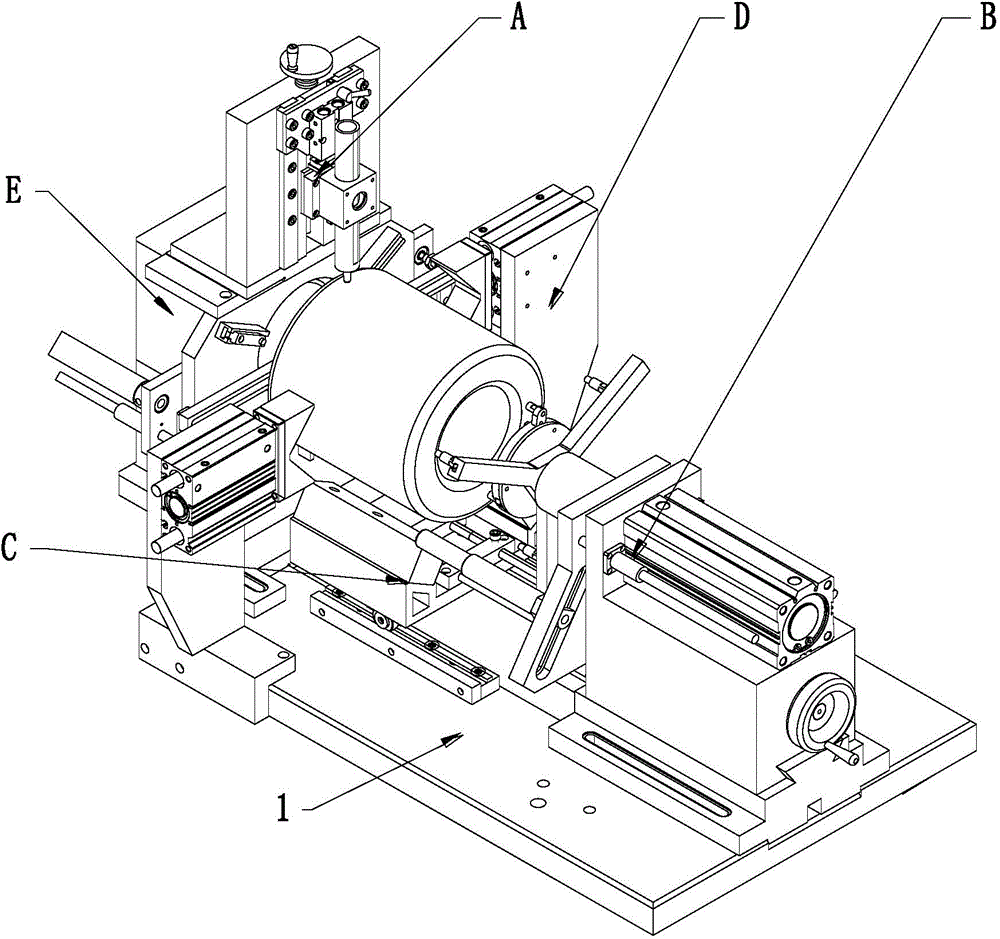

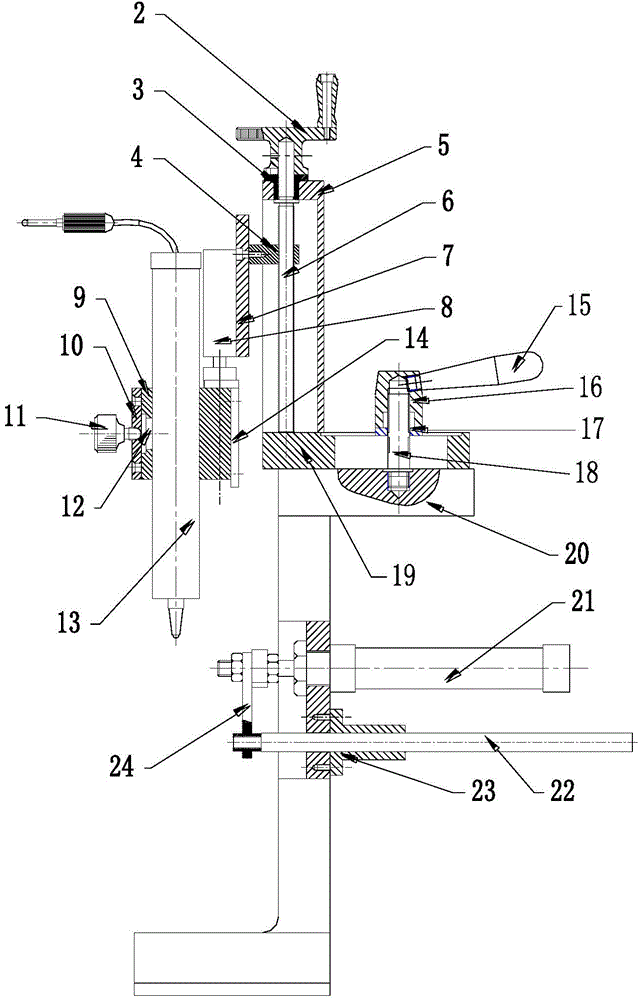

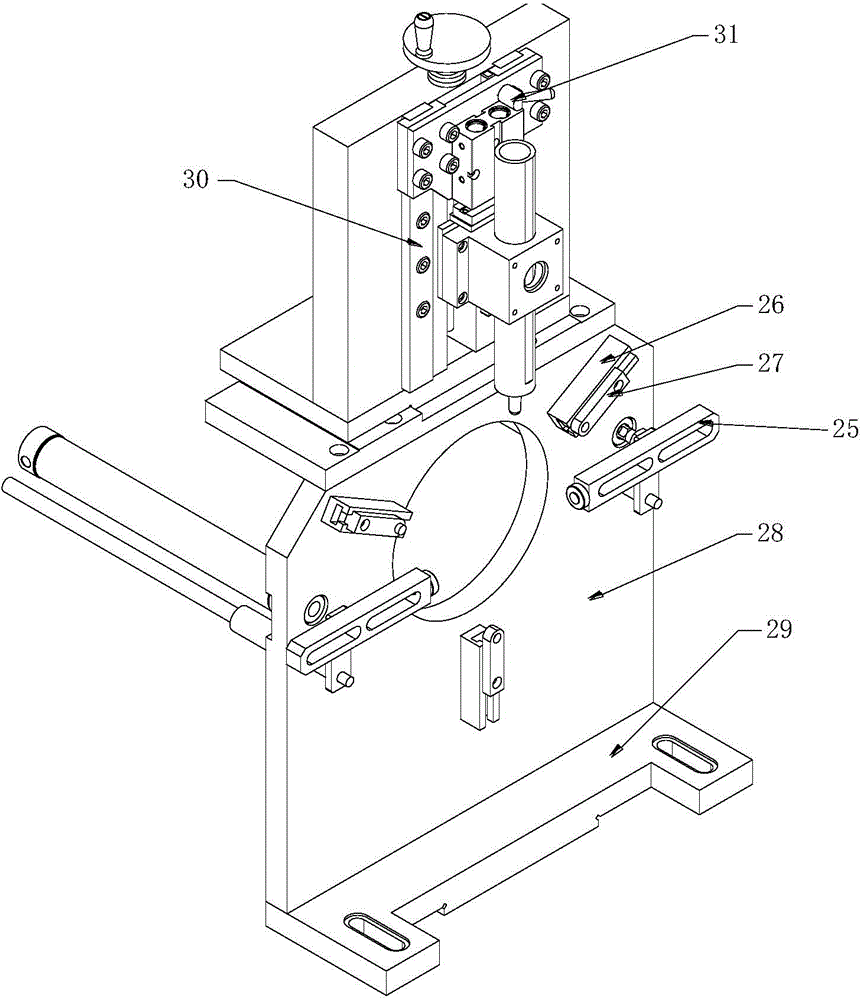

[0018] Take the measurement of large cylindrical roller bearings as an example, put the tested bearing on the bearing pad iron of the trolley to transport the bearing device C, press the "Run" button on the operation panel, and the piston rod of the booster cylinder on the bearing booster device B will extend. Drive the car forward, send the bearing to the rotating mandrel, two cylindrical rollers, and the three-axis cylinder piston rod on the bearing force device B extend out at the same time, clamp the outer ring of the bearing with a V-shaped iron, Then the sensor on the measuring device A automatically lifts the piston rod of the lifting cylinder, which drives the sensor contact to contact the outer ring surface of the bearing, and starts the measurement of the bearing. After the measurement is completed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com