Sintered metal bearing

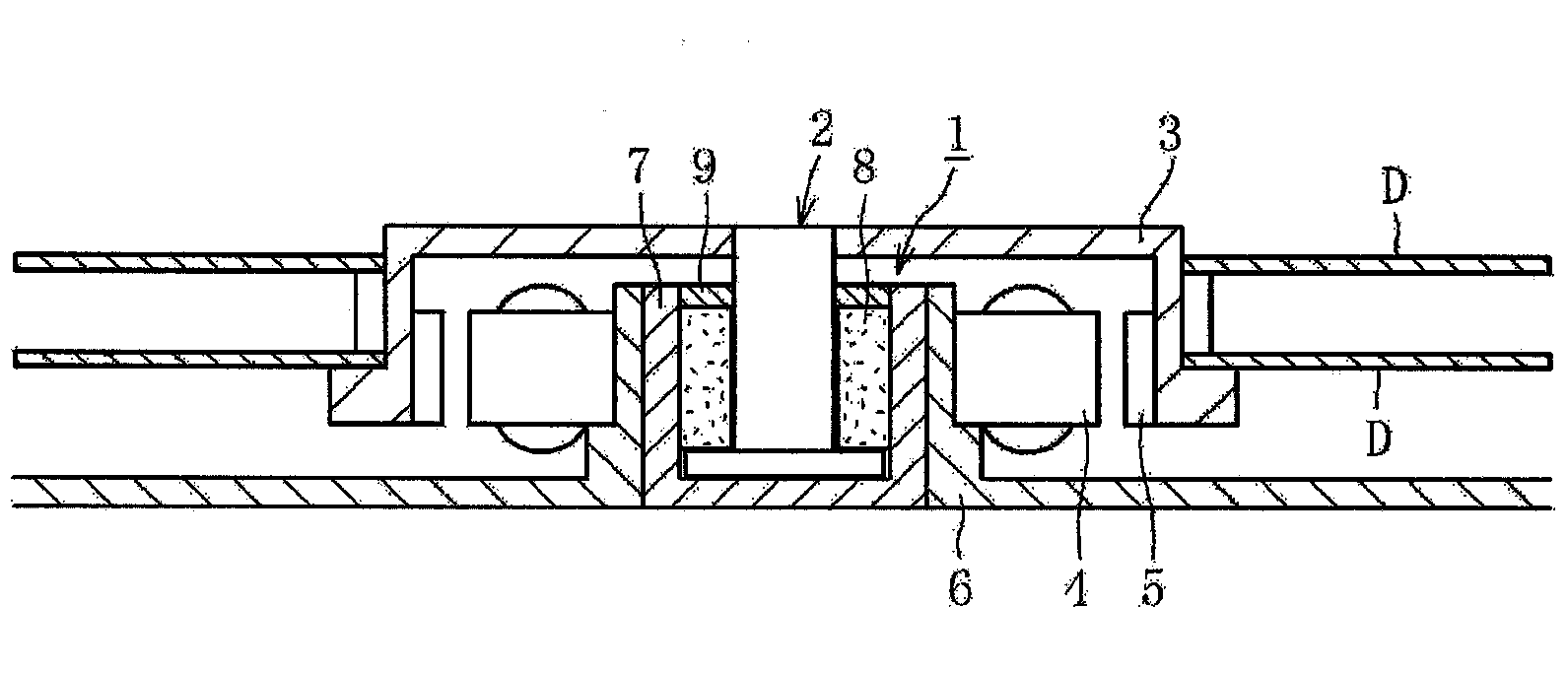

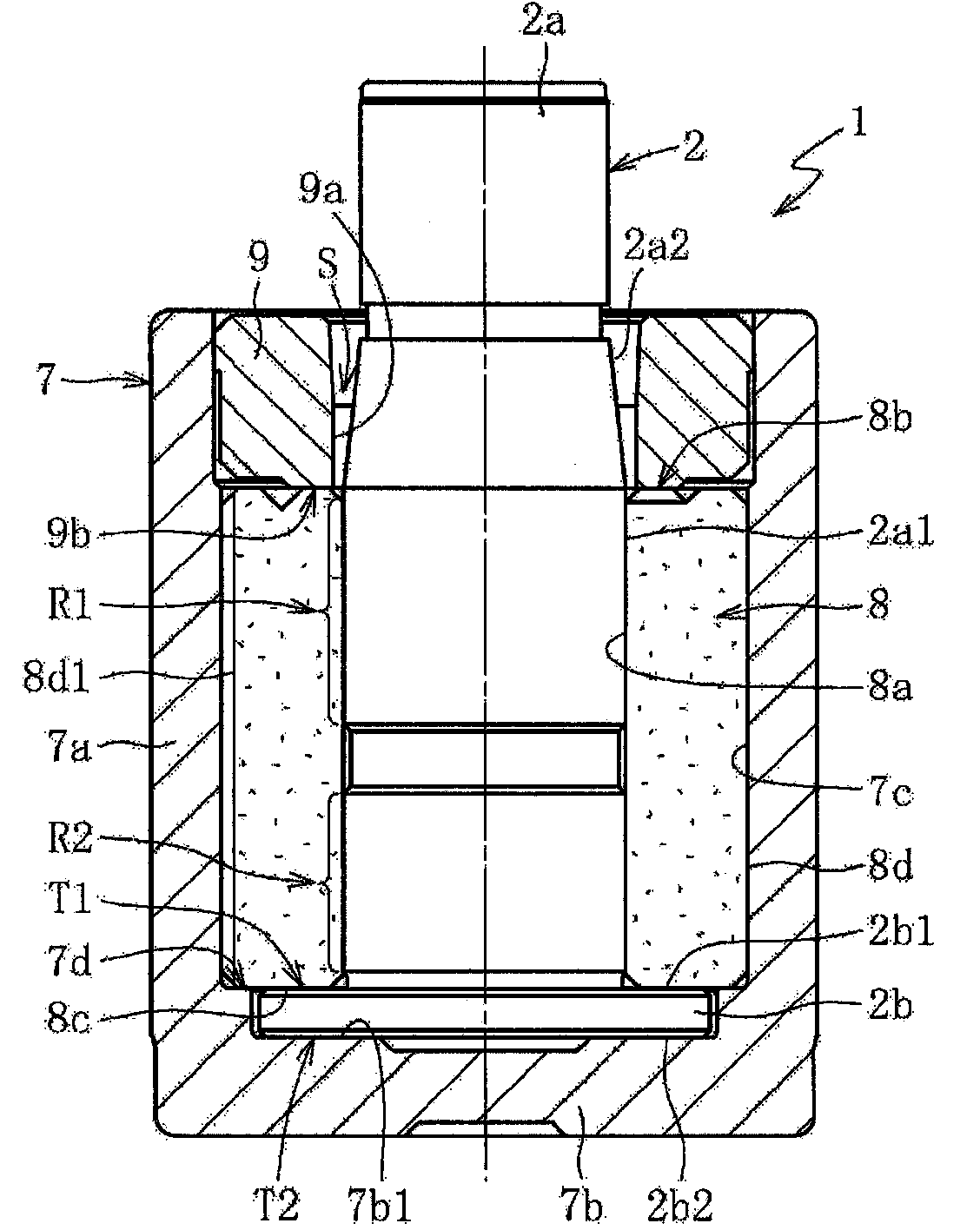

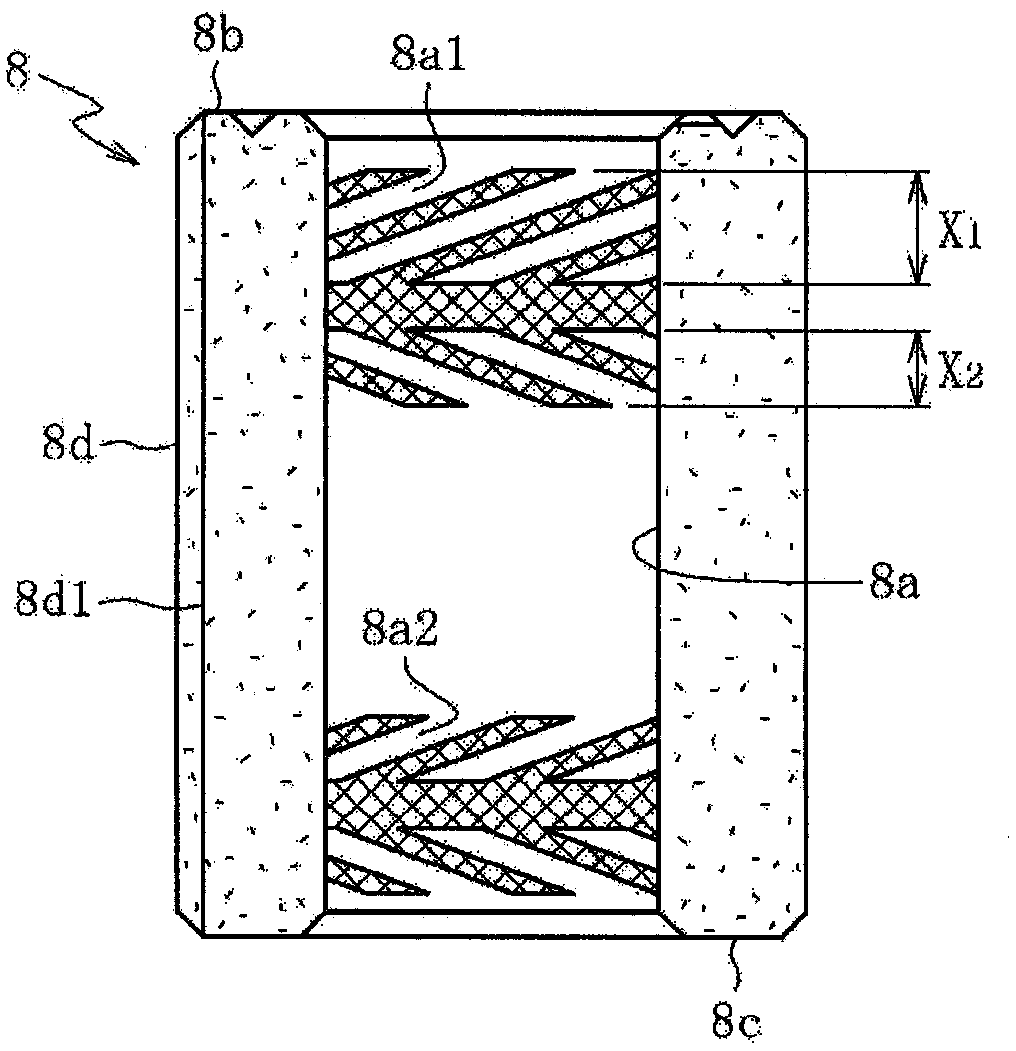

A technology of sintered metal and bearings, which is applied in bearings, bearing components, liquid cushion bearings, etc., and can solve the problems of reduced lubricating oil passing through and easy crushing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0096] In order to verify the effect of the first invention of the present application, sintered metal bearings formed of raw material powders mainly composed of copper-based powder and iron-based powder containing fine copper powder at a certain ratio, and sintered metal bearings formed of raw material powders with a conventional composition For metal bearings, a wear test and an oil permeability measurement test were performed to compare and evaluate each characteristic.

[0097] Here, among the test materials, CE-15 manufactured by Fukuda Metal Foil Powder Co., Ltd. was used as the pure copper powder used as the copper-based powder, and Hegner was used as the pure iron powder used as the iron-based powder. NC100.24 manufactured by Sri Lanka Co., Ltd. and DAP410L manufactured by Daido Special Steel Co., Ltd. were used as the stainless steel powder. In addition, in this experiment, graphite powder, tin powder which is a low-melting-point metal, and phosphorus powder were used...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com