Coupling elastic-support type oil film damper bearing system for gas turbine

An oil film damper, gas turbine technology, applied in bearings, bearing components, liquid cushion bearings, etc., can solve problems such as jeopardizing the stable operation of the rotor system, and achieve the effects of improving the test success rate, improving stability, and reducing vibration overrun

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

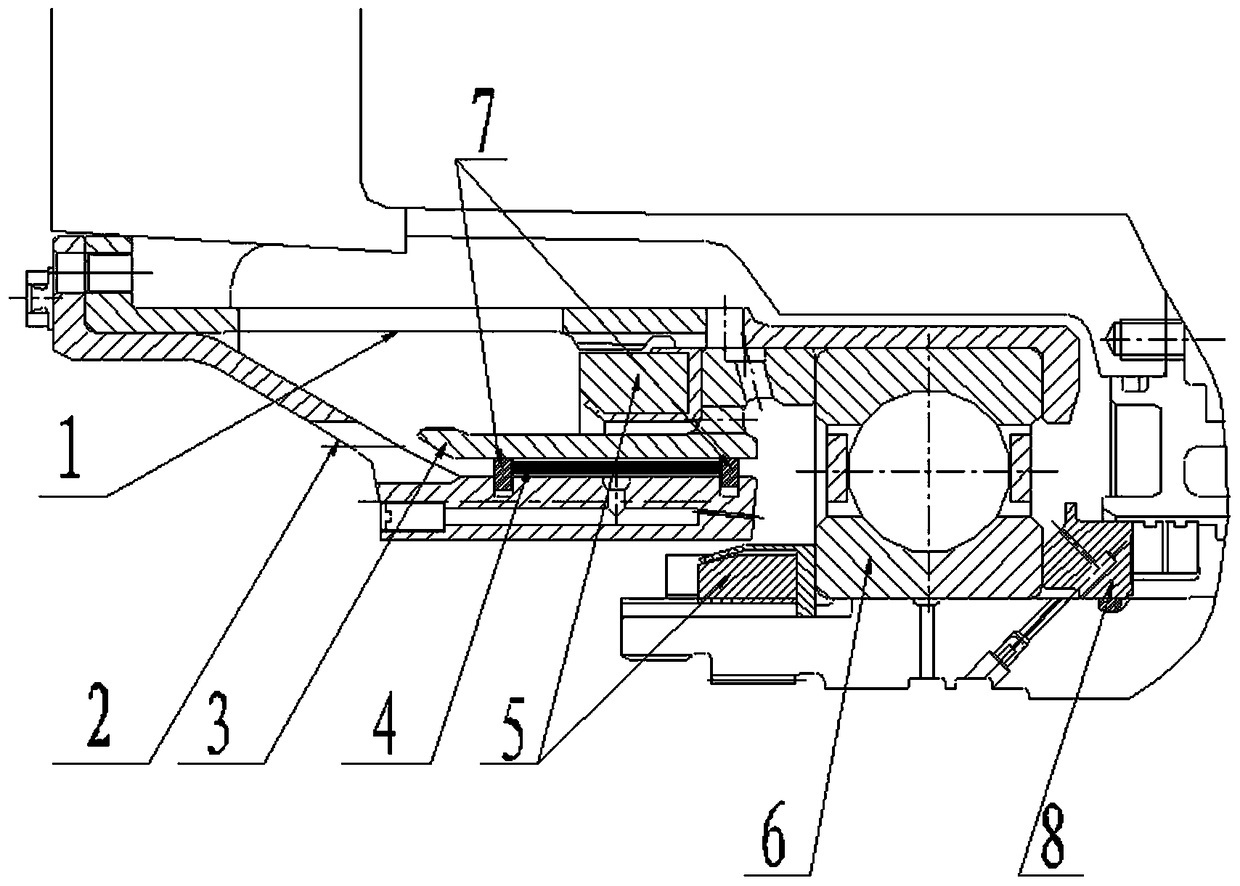

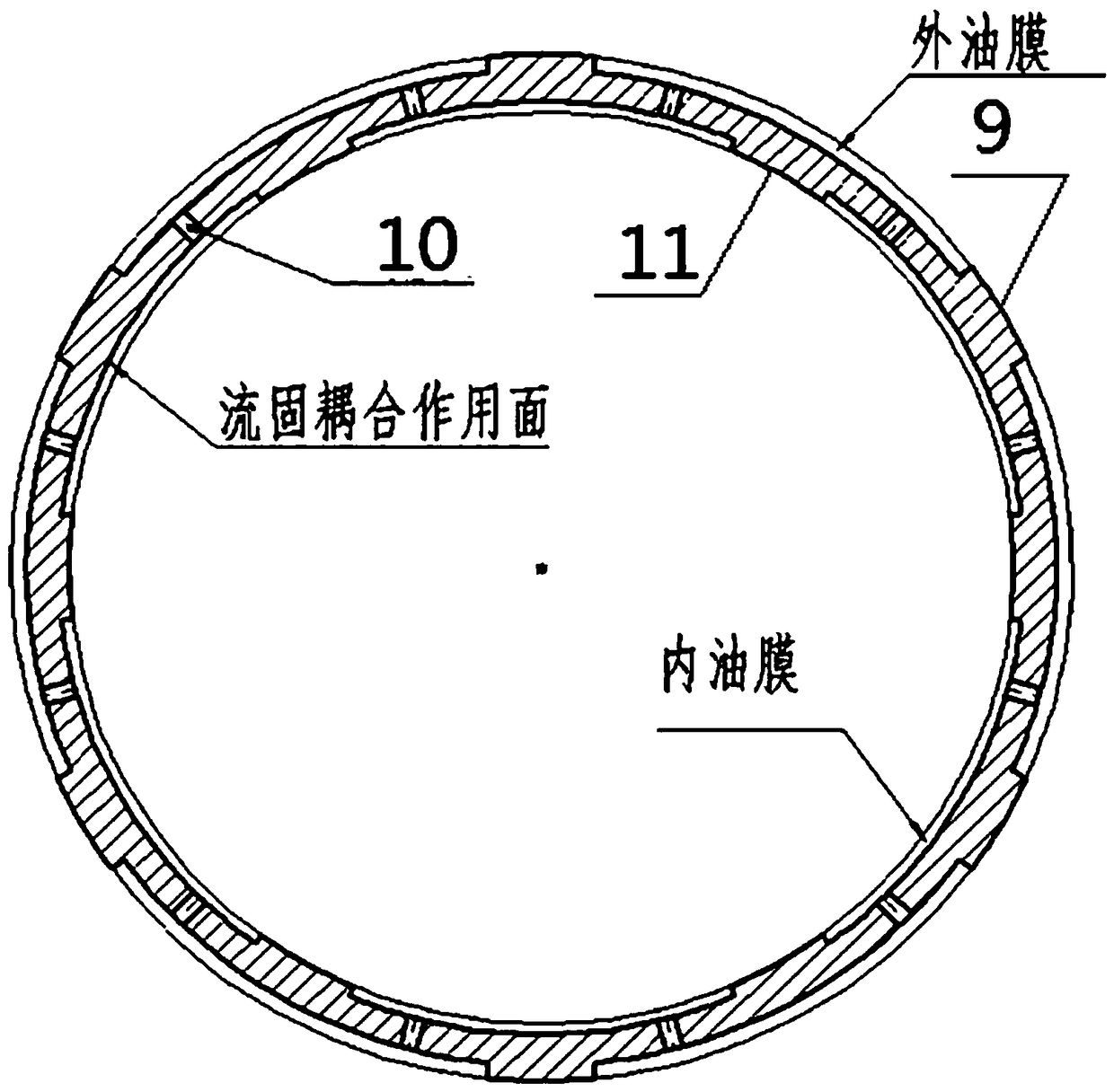

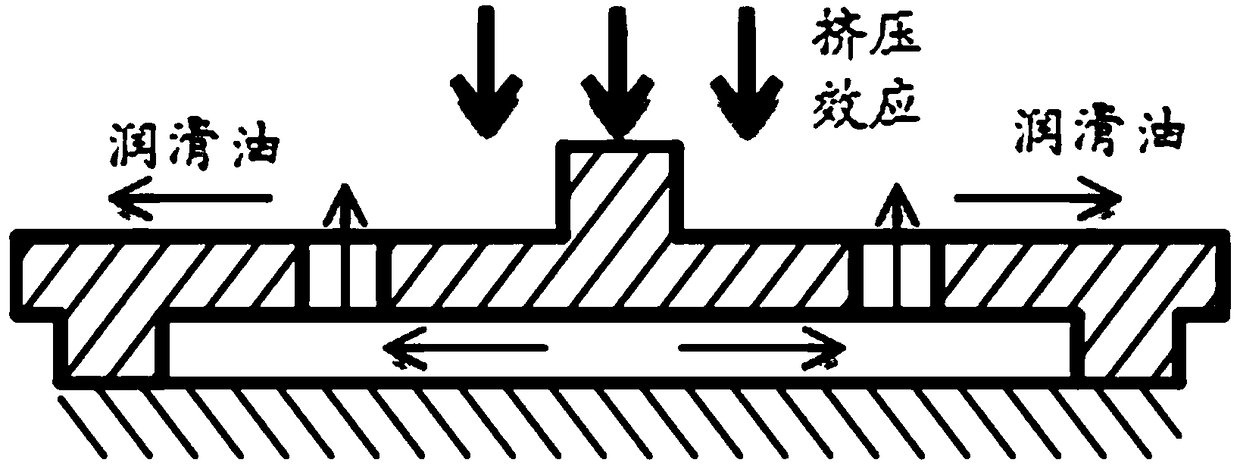

[0022] Referring to the figures, a bearing system for a coupled elastic oil film damper for a gas turbine includes a squirrel cage bearing housing 1, a damper housing 2, a sleeve 3, an elastic ring 4, a lock nut 5, a ball bearing 6, and a sealing ring 7 and the fuel injection ring 8; the elastic ring 4 is clamped between the damper housing 2 and the sleeve 3, and is a cylindrical structure in which the inner and outer bosses are staggered and uniformly distributed, and the inner bosses 11 and the damper housing 2 The outer surface of the damper shell 2 is provided with a circumferential oil supply groove and an oil supply hole for the oil supply of the oil film damper; the outer boss 9 is in clearance fit with the inner surface of the sleeve 3; the surface of the elastic ring 4 It has a specially designed special-shaped small hole structure, and the small hole is a throttle hole 10; the two ends of the oil chamber of the oil film damper are equipped with sealing rings 7 to cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com