Fluid dynamic bearing assembly and motor having the same

一种流体动压轴承、流体动压的技术,应用在轴承元件、电动组件、滑动接触轴承等方向,能够解决加工工艺复杂、制造成本增加、加工制造时间长等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] Now, exemplary embodiments of the present invention will be described in detail with reference to the accompanying drawings. However, it should be noted that the spirit of the present invention is not limited to the embodiments set forth herein, and those skilled in the art understand that by adding, modifying or removing components within the same spirit, the present invention can be easily implemented including the spirit of the present invention. existing inventions or other embodiments within, and these should be construed as being included within the spirit and scope of the present invention.

[0032] Also, throughout the drawings, the same or similar reference numerals will be used to designate the same or similar components having the same function within the scope of similar ideas.

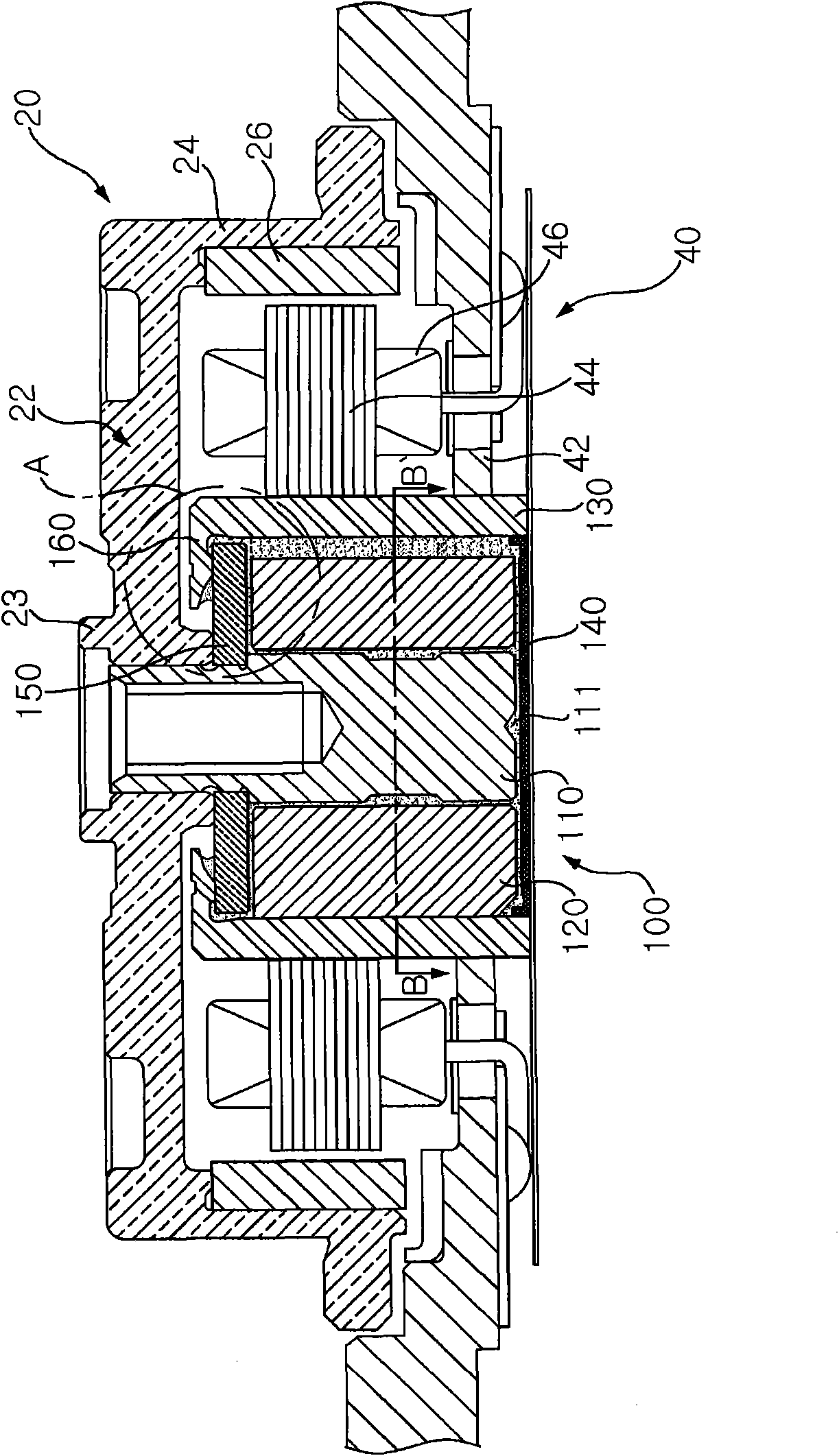

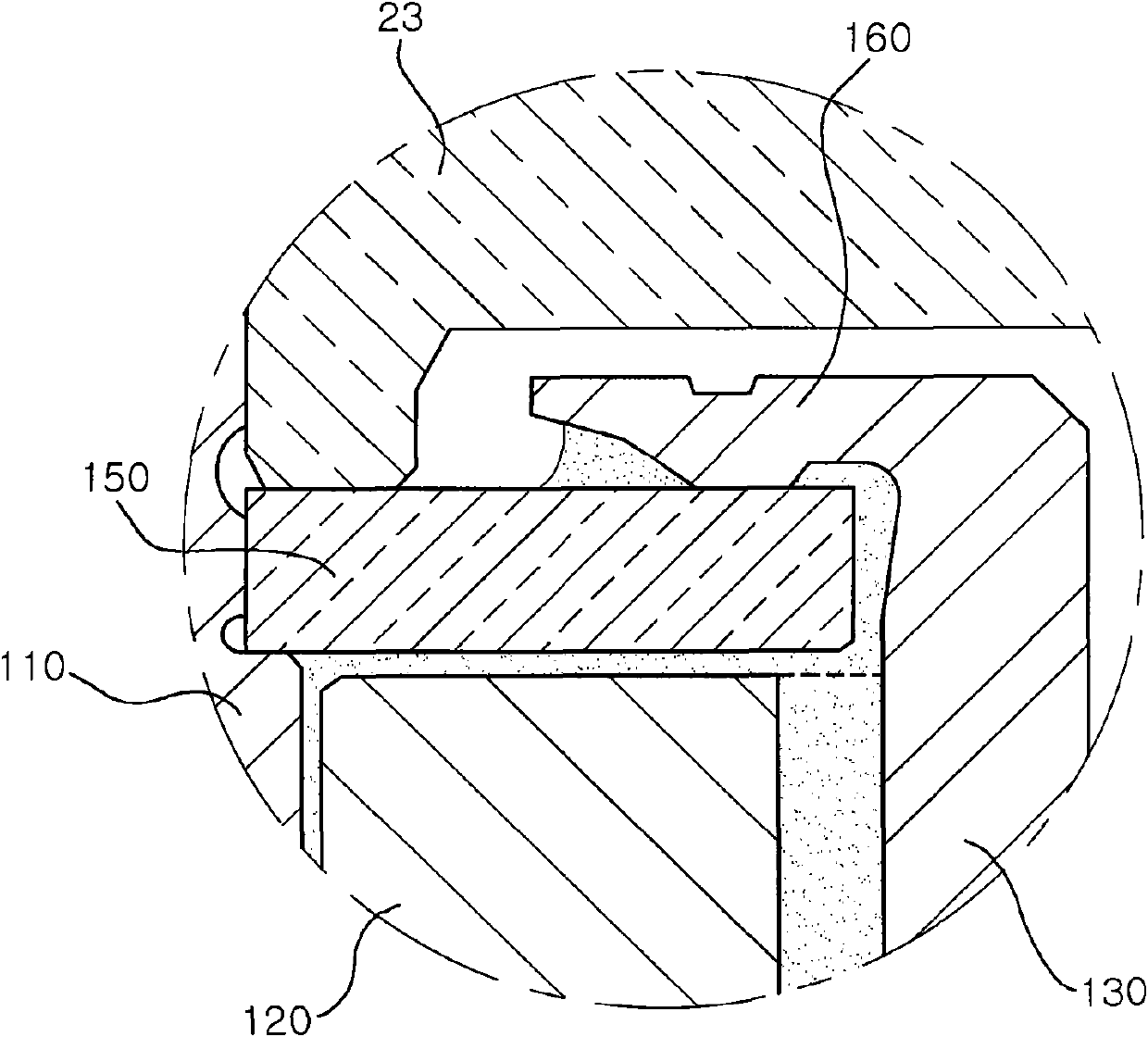

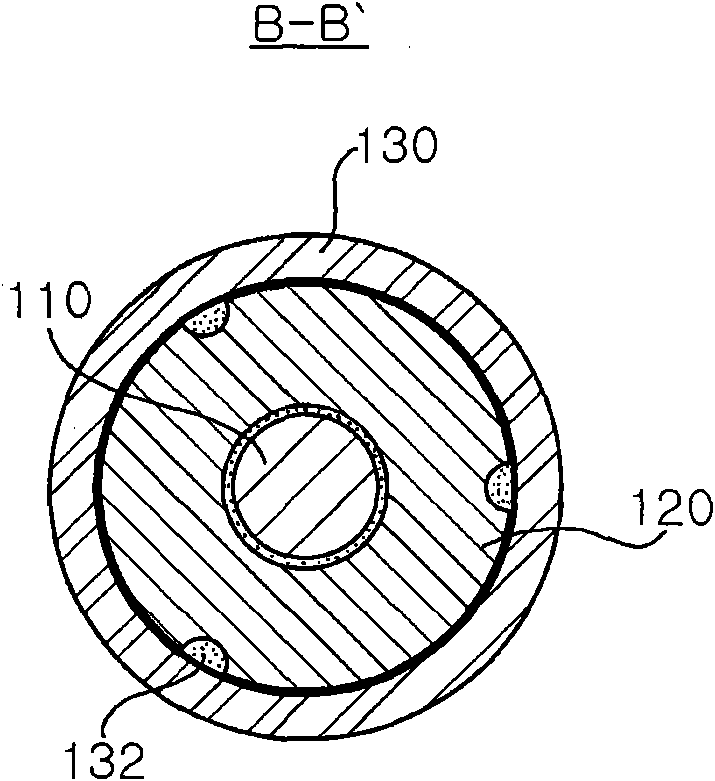

[0033] figure 1 is a sectional view of a motor according to a first exemplary embodiment of the present invention, figure 2 yes figure 1 Partial enlarged cross-sectional view of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com