Radial oil film bearing dynamic mesh updating method based on Fluent

An update method, technology of oil film bearings, applied to bearings, liquid cushion bearings, shafts and bearings, etc., can solve problems such as excessive aspect ratio of bearing oil film grids, distortion of dynamic grids, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The technical solution of the present invention will be further described in conjunction with the embodiments.

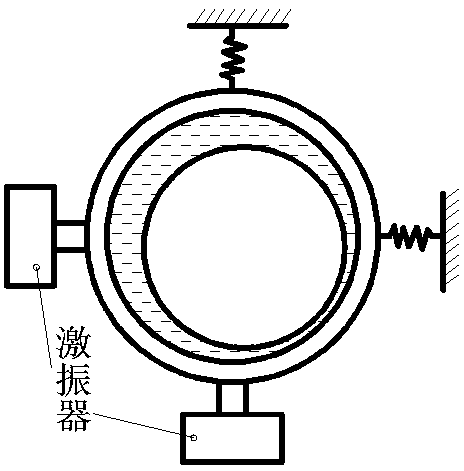

[0045] The structure diagram of the vibration control structure of the bearing bush by the exciter is as follows: image 3 shown. The movement of the bearing pad is controlled by a displacement exciter, and the influence of the amplitude and phase of the exciter on the trajectory of the rotor axis is investigated. The parameters of the calculation example are shown in Table 1.

[0046] Table 1 Physical parameters of bearings, rotors and lubricating oil

[0047]

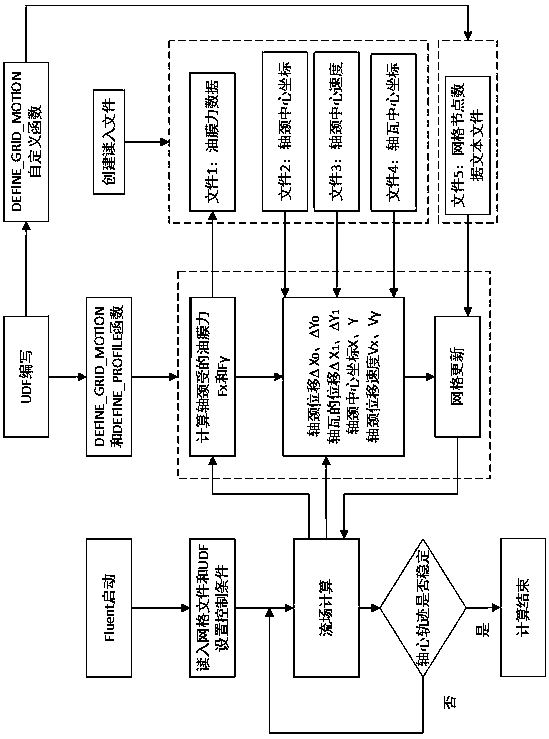

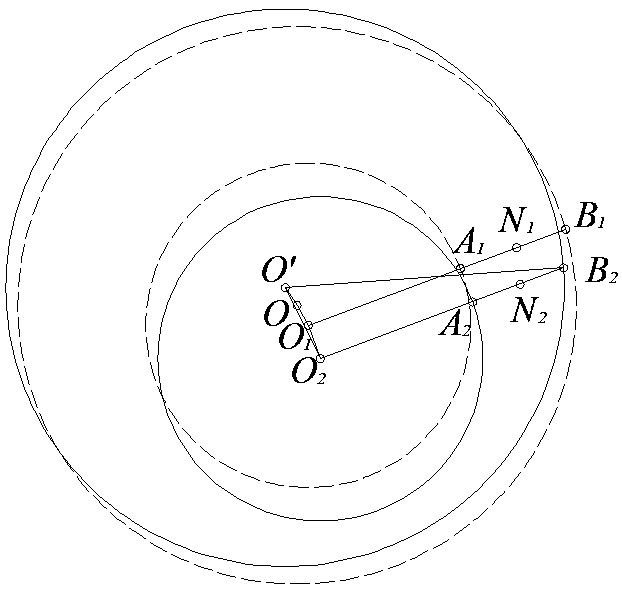

[0048] Such as Figure 1-4 As shown, the mesh node update in the Fluent software dynamic mesh update process is determined according to the displacement of the journal and bearing pad. The core of the grid update method is the algorithm for solving node coordinates. The schematic diagram of the grid node solution is as follows: figure 2 shown. Based on a Fluent-based radial oil film bearing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com