Data tracking method of boiler steam drum manufacture process

A boiler steam drum and manufacturing process technology, applied in electromagnetic radiation induction, recording medium used by machines, instruments, etc., can solve problems such as no effective data tracking method, and achieve the effect of saving labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

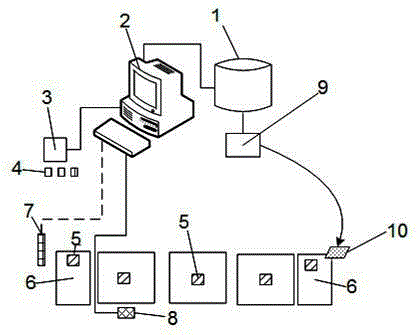

[0016] Such as figure 1 The structural diagram of the boiler steam drum manufacturing process data tracking system is shown in the figure. The boiler steam drum manufacturing execution system (MES) 1 generates the material BOM table according to the steam drum order, and directly forms the material list and material number for different processing parts 6. The material number includes Material manufacturer data, material batch data, material attribute data, storage date information, production serial number information are stored in the MES database 2 with the material number as the index.

[0017] The boiler steam drum manufacturing execution system (MES) 1 outputs the material number to the network label printer 3 through a wired network, and directly prints out the label 4, and the material number information is output as a two-dimensional code or a bar code.

[0018] Insert the label 4 containing the material number information into a label box 5 with a strong magnet at th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com